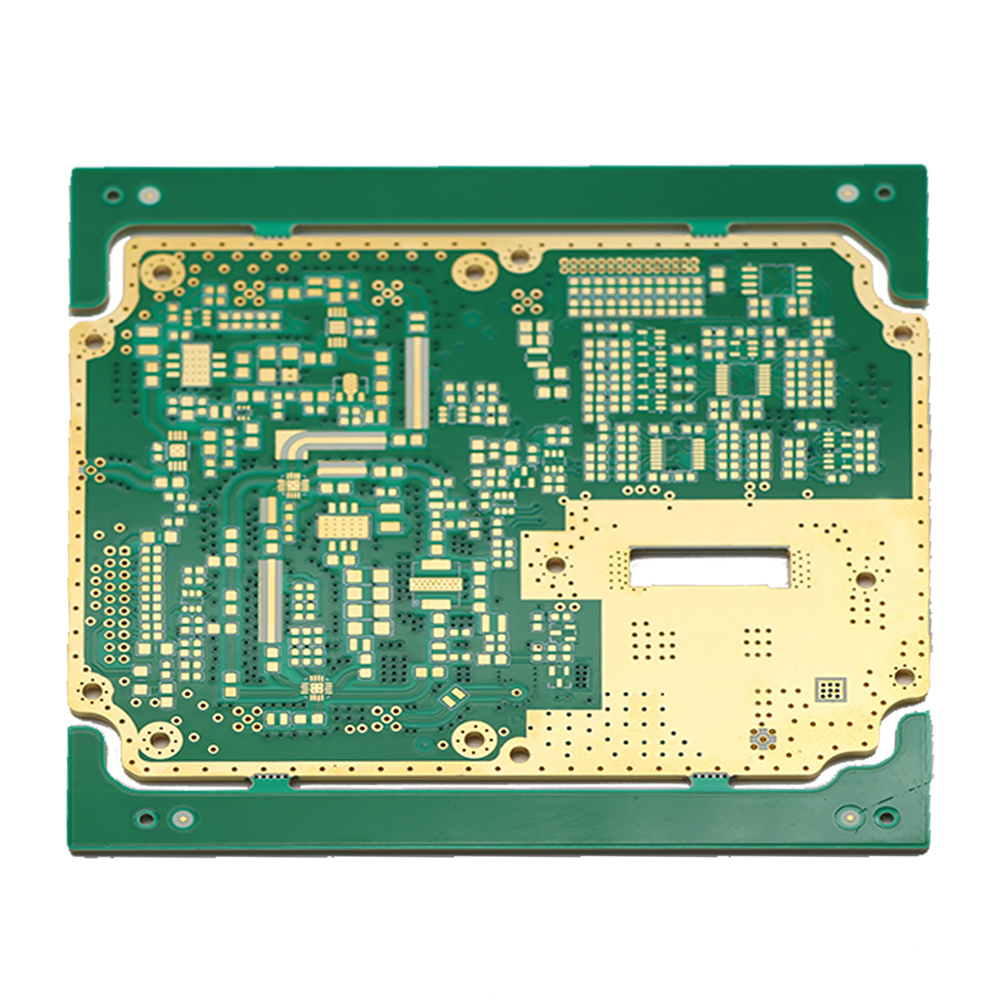

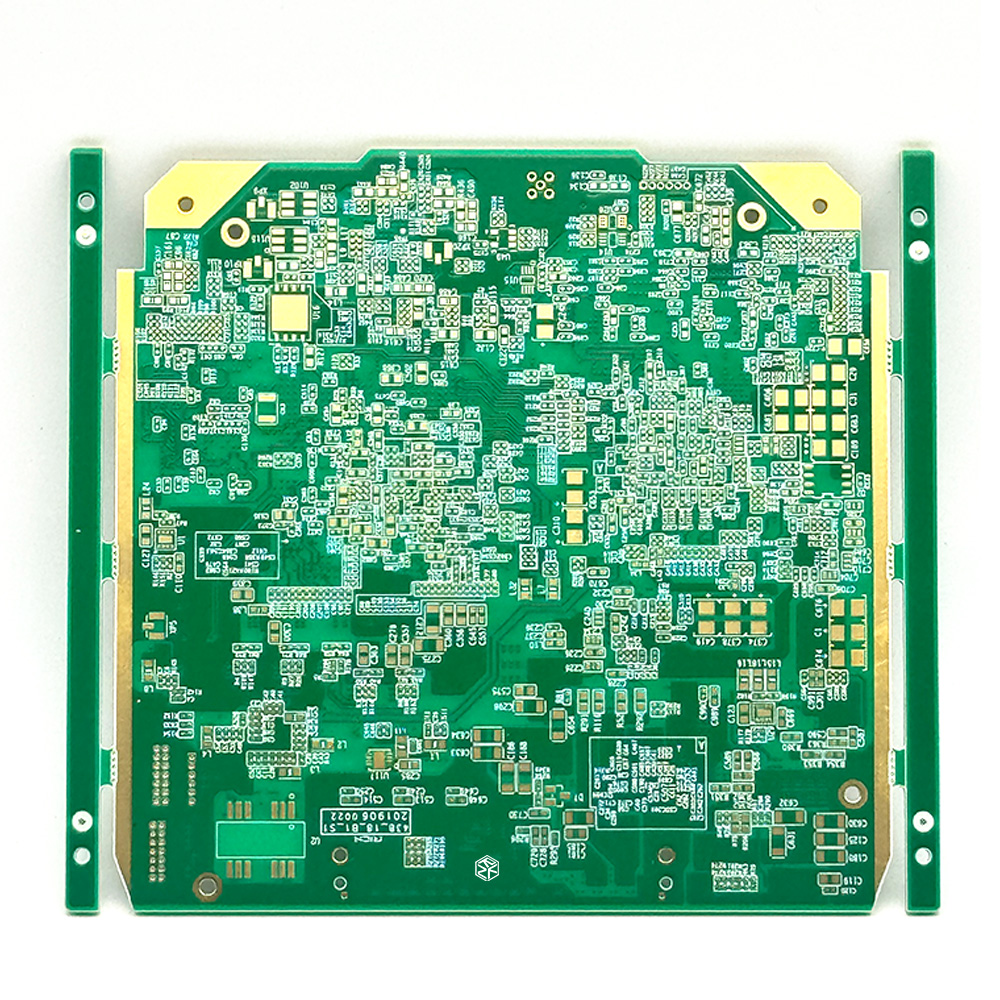

Module Na gani HDI PCB Optical Module Gold Finger PCB

Umarnin samar da samfur

| Nau'in | biyu Layer HDI, impedance, guduro toshe rami |

| Al'amari | Panasonic M6 Copper-Clad Laminate |

| Yawan Layer | 10L |

| Kaurin allo | 1.2mm |

| Girman guda ɗaya | 150*120mm/1SET |

| Ƙarshen saman | MAI GIRMA |

| Kaurin jan karfe na ciki | 18 ku |

| Kaurin jan ƙarfe na waje | 18 ku |

| Launi na solder mask | kore (GTS, GBS) |

| Launin siliki | fari (GTO,GBO) |

| Ta hanyar magani | 0.2mm ku |

| Yawa na inji hakowa rami | 16W/㎡ |

| Yawa na Laser hakowa rami | 100W/㎡ |

| Min ta hanyar girman | 0.1mm |

| Min layin nisa/ sarari | 3/3 mil |

| Rabon buɗe ido | 9 mil |

| Lokutan latsawa | 3 lokaci |

| Lokutan hakowa | 5 lokaci |

| PN | E240902A |

Maɓallin Sarrafa Maɓalli a cikin Samar da Module Na gani HDI PCBs yatsa na Zinare

- 1, Daidaitaccen Etching Control The wayoyi na zinariya yatsunsu da HDI PCBs ne sosai m, yin iko da etching aiwatar musamman muhimmanci. Rashin ƙazafi na iya haifar da faɗuwar layi marar daidaituwa, gajeriyar kewayawa, ko buɗaɗɗen da'irori. Sabili da haka, dole ne a yi amfani da kayan aiki mai mahimmanci, kuma gyare-gyare na yau da kullum ya zama dole don tabbatar da daidaito da daidaito a cikin tsarin etching.

3, Lamination Process Control Lamination wani muhimmin mataki ne inda mahara PCB yadudduka aka guga man tare. Sarrafa zafin jiki, matsa lamba, da lokaci yayin lamination yana da mahimmanci don tabbatar da ingantaccen haɗin yadudduka da kauri na allo. Lamination mara kyau na iya haifar da lalacewa ko ɓarna, yana shafar aikin lantarki da ƙarfin injina.

4, Gold Finger Plating Kauri Control The kauri daga cikin zinariya plating a kan zinariya yatsunsu kai tsaye rinjayar saka rayuwa da lamba AMINCI. Idan platin gwal ɗin ya yi bakin ciki sosai, zai iya ƙarewa da sauri; idan yayi kauri, yana kara tsada. Sabili da haka, yayin aiwatar da plating, lokacin plating na zinari da yawa na yanzu dole ne a sarrafa shi sosai don tabbatar da kauri na plating ya dace da ma'auni (yawanci 30-50 microinches).

5, Ipedance Control da Testing Optical module HDI PCBs sau da yawa rike high-gudun sigina, yin impedance iko muhimmanci. A lokacin samarwa, ya kamata a yi amfani da kayan gwajin impedance don saka idanu da auna alamun sigina masu mahimmanci a cikin ainihin lokacin, tabbatar da cewa impedance yana cikin kewayon ƙira (misali, 100 ohms). Ƙunƙarar da ba ta yarda ba na iya haifar da al'amuran amincin sigina, kamar tunani da magana.

6.Ikon Sayar da Ingancin Sayar da ɗimbin ɗimbin abubuwan da ke cikin PCBs na gani, dole ne tsarin siyarwar ya zama daidai sosai. Ana buƙatar ci gaba da siyar da siyar da kayan aikin igiyar ruwa, kuma dole ne a sarrafa bayanan martabar zafin jiki mai ƙarfi don tabbatar da ƙarfin haɗin gwiwa da amincin haɗin lantarki.

7, Surface Cleaning da Kariya A kowane mataki na samar, da PCB surface dole ne a kiyaye tsabta don kauce wa kura, yatsa, ko hadawan abu da iskar shaka sharan. Waɗannan gurɓatattun na iya haifar da gajerun wando na lantarki ko kuma su shafi ingancin plating. Bayan samarwa, ya kamata a yi amfani da kayan kariya masu dacewa don hana danshi da gurɓataccen abu daga shiga.

8, Quality dubawa da Tabbatarwa m ingancin dubawa, ciki har da gani dubawa, lantarki gwajin, da kuma aikin gwaji, suna da muhimmanci. Hanyoyin dubawa gama gari sun haɗa da Inspection Optical Inspection (AOI), gwajin gwajin tashi sama, da duban X-ray don tabbatar da cewa kowane PCB ya cika ƙayyadaddun ƙira da ƙa'idodi masu inganci.

Muhimmancin Gudanarwa a Module HDI PCBs

- Girma da Tazarar Tazara: Faɗin da tazarar yatsun zinare suna buƙatar kulawa sosai don tabbatar da dacewa da masu haɗin. Gabaɗaya, faɗin yatsun zinare shine 0.5mm, tare da tazarar 0.5mm.

- Edge Chamfering: Ana buƙatar chamfering yawanci akan gefuna na PCB inda yatsun zinare suke don sauƙaƙe shigar da santsi a cikin ramummuka.

Ƙididdigar Layer da Stacking: HDI PCBs yawanci sun haɗa da ƙira mai yawa don samar da ƙarin zaɓuɓɓukan haɗin lantarki. Ana buƙatar la'akari da ƙidayar Layer da ƙirar ƙira don tabbatar da amincin sigina da amincin iko.

Microvias: Yin amfani da fasahar microvia, kamar makafi da binne ta hanyar, na iya rage tsayin haɗin kai yadda ya kamata, ta haka rage jinkirin sigina da asara. Waɗannan microvias suna buƙatar daidaitaccen iko na matsayi da girman su.

Dinsity Din: Saboda babban yawan zirga-zirgar allunan HDI, dole ne a biya kulawa ta musamman ga faɗin da tazarar sawu. Yawanci, faɗin alamar suna mil 3-4, kuma tazara kuma mil 3-4 ne.

3.Mutuncin Sigina

Bambance-bambancen Hanya Biyu: watsa sigina mai sauri wanda aka saba amfani da shi a cikin na'urori masu gani na gani yana buƙatar bambance-bambancen bibiyu don rage tsangwama na lantarki da kuma tunanin sigina. Tsawon tsayi da tazarar nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan tsiro da tsayi da tsayi da tsayin tsayi da tsayi suna buƙatar daidaitawa, suna tabbatar da ikon sarrafa impedance a cikin kewayon da ya dace (misali, 100 ohms).

Sarrafa Impedance: A cikin siginar siginar sauri mai sauri, kulawa mai ƙarfi yana da mahimmanci. Ana iya samun madaidaicin matsewa ta hanyar daidaita nisa, tazara, da tari.

Ta hanyar Amfani: Ya kamata a rage yawan amfani da ta hanyar, yayin da suke gabatar da iyawar parasitic da inductance, yana shafar ingancin sigina. A lokacin da ya cancanta, dace ta iri (kamar makafi da binne vias) da kuma wurare ya kamata a zabi.

Haɓaka Capacitors: Daidaitaccen jeri na ƙwanƙwasa capacitors yana taimakawa daidaita ƙarfin wutar lantarki da rage hayaniyar wuta.

Ƙirƙirar Jirgin Wuta na Wuta: Ƙarfafa ƙira mai ƙarfi na jirgin sama yana tabbatar da rarraba kayan aiki na yanzu kuma yana rage tsangwama na lantarki (EMI).

Gudanar da thermal: Tun da na'urori masu gani suna haifar da zafi mai mahimmanci yayin aiki, yakamata a yi la'akari da hanyoyin sarrafa zafin jiki a cikin ƙira, kamar yin amfani da tazarar zafi, kayan sarrafawa, ko nutsewar zafi don haɓaka haɓakar zafin zafi.

6.Zaɓin kayan aiki

Material Substrate: Zaɓi abubuwan da suka dace don aikace-aikacen mitoci masu girma, kamar polyimide (PI) ko fluoropolymers, don tabbatar da abin dogaro da ingantaccen watsa sigina.

Solder Mask: Yi amfani da babban zafin jiki, kayan abin rufe fuska mai ƙarancin asara don tabbatar da kariyar alamun da aikin lantarki.

PCBs HDI yatsa na zinari ana amfani da su ko'ina a fagage daban-daban saboda girman girmansu da halayen halayensu:

5, Medical na'urorin: A high-bukatar likita kayan aiki kamar CT scanners, MRI inji, da kuma sauran bincike kayan aikin, zinariya yatsa HDI PCBs tabbatar da m watsa bayanai da kuma abin dogara aiki na kayan aiki.

- 6, Aerospace: Wadannan PCBs ake amfani da iko tsarin na tauraron dan adam, jirgin sama, da kuma sararin samaniya, kamar yadda za su iya yin tsayayya da matsananci yanayi yanayi yayin da rike high yi.

- 7, Industrial Control: A cikin filin na masana'antu aiki da kai, PLCs (Programmable Logic Controllers), da kuma masana'antu mutummutumi, zinariya yatsa HDI PCBs samar da abin dogara iko da siginar watsa.

Yatsar zinari

Cikakken Gabatarwa zuwa Yatsun Zinare

Yatsun zinari suna nufin wuraren da aka yi wa zinari a gefen allon da'ira da aka buga (PCB). Yawancin lokaci ana amfani da su don yin haɗin lantarki tare da masu haɗawa. Sunan "yatsa na zinari" ya fito ne daga bayyanar su: sassan da aka yi da zinari-kamar zinariya suna kama da yatsunsu. Ana amfani da yatsun zinari a cikin PCBs masu iya sakawa, kamar sandunan ƙwaƙwalwa, katunan zane, da sauran na'urori, don haɗawa da ramummuka. Babban aikin yatsun zinari shine samar da ingantattun hanyoyin haɗin lantarki ta hanyar daɗaɗɗen gwal mai ɗaukar nauyi yayin tabbatar da juriya da juriya na lalata.

Rarraba Yatsun Zinare

Za a iya rarraba yatsun zinari bisa la'akari da aikinsu, matsayi, da tsarin masana'antu:

Haɗin Wutar Lantarki na Zinare: Ana amfani da waɗannan yatsun zinare galibi don samar da tsayayyen haɗin wutar lantarki, kamar a cikin sandunan ƙwaƙwalwa, katunan zane, da sauran na'urorin toshewa. Suna isar da siginar lantarki ta hanyar sanya su cikin ramummuka akan motherboard ko wasu na'urori.

Yatsun Zinare Mai Ba da Wutar Lantarki: Ana amfani da waɗannan don samar da wutar lantarki ko haɗin ƙasa, tabbatar da cewa na'urori sun sami ingantaccen shigar wutar lantarki.

2.Dangane da Matsayi:

Fingers na Edge Gold: Yawanci suna a gefen PCB, ana amfani da su don haɗin ramin kuma ana samun su a cikin sandunan ƙwaƙwalwa, katunan zane, da kayan sadarwa. Wannan shine mafi yawan nau'in yatsan zinare.

Fingers ɗin Zinare Ba-Edge: Waɗannan yatsun zinare ba su kasance a gefen PCB ba amma an sanya su a ciki don takamaiman haɗin gwiwa ko ayyuka, kamar wuraren gwaji ko haɗin haɗin ginin ciki.

3.Dangane da Tsarin Samfura:

Immersion Zinare Fingers: Ana ƙirƙira waɗannan ta amfani da tsarin saka sinadarai don shafa ruwan gwal akan foil ɗin tagulla. Suna da santsi, lafiyayyan ƙasa amma siraren zinari, yawanci ana amfani da su don ƙananan haɗin lantarki.

Yatsun Zinare Masu Wutar Lantarki: Anyi ta amfani da tsarin lantarki, waɗannan yatsun zinari suna da kauri mai kauri kuma sun fi jure lalacewa, dacewa da ingantaccen haɗin lantarki da ke buƙatar shigarwa akai-akai da cirewa, kamar a cikin sandunan ƙwaƙwalwa da katunan zane. Wannan tsari yawanci yana amfani da kauri mai kauri na 30-50 microinches don tabbatar da dorewa da aiki mai kyau.

4.Dangane da Hanyar Haɗi:

Saka Fingers Zinare Madaidaici: An saka kai tsaye cikin ramin, elasticity ɗin ramin yana kama yatsun gwal. Ana amfani da wannan hanyar sosai a cikin sandunan ƙwaƙwalwa da katunan zane.

Latch Gold Fingers: Haɗa ta amfani da latches ko wasu na'urori masu ɗaurewa, suna ba da ƙarin gyaran inji, wanda aka saba amfani da shi don manyan kayayyaki da aikace-aikacen da ke buƙatar ƙarin haɗin kai.

Halayen Aikace-aikacen Yatsan Zinare

- Babban Haɓakawa da Kwanciyar hankali: Babban kayan yatsan zinari shine platin zinare, wanda ke da kyakkyawan aiki da kwanciyar hankali, yana ba da ingantaccen aikin lantarki.

- Juriya na Sawa: Aikace-aikacen da suka haɗa da sakawa akai-akai da cirewa suna buƙatar yatsun zinariya don samun juriya mai kyau. Layin zinari yana ba da wannan kariyar, yana tabbatar da cewa yatsun zinare ba su ƙarewa ko oxidize cikin sauƙi yayin amfani.

- Resistance Lalacewa: Layin zinari akan yatsun zinare ba wai yana samar da aiki kawai ba amma kuma yana tsayayya da abubuwa masu lalata a cikin muhalli, yana tsawaita tsawon rayuwar yatsun gwal.

Rarraba Modulolin gani

1.Dangane da Gudun Watsawa:

10G Optical Modules: Ana amfani dashi don aikace-aikacen Gigabit Ethernet 10.

Modulolin gani na 25G: An tsara don 25 Gigabit Ethernet.

40G Optical Modules: Ana amfani dashi a cikin cibiyoyin sadarwa na Gigabit Ethernet 40.

100G Optical Modules: Ya dace da cibiyoyin sadarwa na Gigabit Ethernet 100.

400G Optical Modules: Don aikace-aikacen 400 Gigabit Ethernet mai ƙarfi mai ƙarfi.

2.Dangane da Nisan Watsawa:

Modules Na gani na gajere (SR): Yawanci suna goyan bayan nisa har zuwa mita 300 ta amfani da fiber multimode (MMF).

Modules na gani mai tsayi (LR): An ƙera shi don nisa har zuwa kilomita 10 ta amfani da fiber-mode fiber (SMF).

Extended Range Optical Modules (ER): Zai iya watsa har zuwa kilomita 40 akan SMF.

Modules Na gani Mai Doguwa (ZR): Taimakon nisan sama da kilomita 80 akan SMF.

3.Dangane da Tsawon Wave:

850nm Modules: Gabaɗaya ana amfani da su don watsa gajeriyar hanya akan fiber multimode.

1310nm Modules: Ya dace da watsa tsaka-tsakin matsakaici akan fiber yanayin yanayi guda ɗaya.

1550nm Modules: Ana amfani da shi don watsawa mai nisa, musamman akan fiber na yanayi guda ɗaya.

4.Dangane da Factor Factor:

SFP (Small Form-Factor Pluggable): An fi amfani da shi don cibiyoyin sadarwa na 1G da 10G.

SFP+ (Ƙaramin Ƙarfafa Faɗakarwa-Factor Pluggable): Ana amfani da shi don cibiyoyin sadarwa na 10G tare da babban aiki.

QSFP (Quad Small Form-Factor Pluggable): Ya dace da aikace-aikacen 40G.

QSFP28: An tsara shi don cibiyoyin sadarwa na 100G, yana ba da mafi girman bayani mai yawa.

CFP (C Form-Factor Pluggable): Ana amfani da shi a cikin aikace-aikacen 100G da 400G, wanda ya fi girma fiye da samfuran SFP/QSFP.

5.Dangane da Aikace-aikacen:

Modules na gani na Cibiyar Data: An ƙirƙira don watsa bayanai cikin sauri a cikin cibiyoyin bayanai.

Modules Optical Modules: Ana amfani da su a kayan aikin sadarwa don watsa bayanai mai nisa.

Modulolin gani na masana'antu: Gina don mahalli masu ruguza, tare da babban juriya ga bambancin zafin jiki da tsangwama na lantarki.

Yadda Ake Bambance Ƙididdigar Matakin HDI

Bine Vias: Ramukan da ke cikin allo, ba a iya gani daga waje.

Vias Makafi: Ramukan da ake iya gani daga waje amma ba a gani ba.

Ƙididdiga Mataki: Adadin nau'ikan makafi daban-daban, kamar yadda aka duba daga ƙarshen allo, ana iya bayyana shi azaman ƙidayar mataki.

Ƙididdiga na Lamination: Yawan lokutan makafi/binne vias suna wucewa ta maɓalli da yawa ko yadudduka na wuta.

An ƙera PCB ta amfani da laminate na Panasonic M6

An ƙera PCB ta amfani da laminate na Panasonic M6. Muna da ƙwarewa mai yawa a cikin wannan filin kuma mun san yadda ake amfani da cikakken aikin kayan aikin Panasonic M6 ta hanyar mai da hankali kan waɗannan yankuna:

1. Zabin kayan aiki da dubawa

Zaɓin Mai Bayar da Tsayayyar: Zabi sananne kuma abin dogaro Panasonic M6 masu siyar da laminate na jan karfe don tabbatar da daidaito da daidaitattun kayan aiki. Ana iya yin haka ta hanyar kimanta cancantar mai kaya, iyawar samarwa, da tsarin sarrafa inganci. Shekarunmu na gwaninta sun ba mu damar kafa dogon lokaci, haɗin gwiwa tare da masu samar da inganci, tabbatar da ingancin kayan aiki daga tushe.

Duban Abu: Bayan karɓar kayan laminate ɗin jan ƙarfe, gudanar da bincike mai ƙarfi don bincika lahani kamar lalacewa ko tabo da auna sigogi kamar kauri da girma don tabbatar da sun cika buƙatun. Hakanan za'a iya amfani da na'urorin gwaji na musamman don gwada kayan lantarki na kayan, ƙarfin zafin jiki, da sauran alamun aiki don tabbatar da sun cika buƙatun ƙira. Ƙwararrun gwajin mu na yin amfani da kayan aiki na ci gaba da tsauraran matakai don tabbatar da cewa ba a kula da cikakkun bayanai ba.

2. Haɓaka Zane

Zane-zanen Da'irar: Dangane da halayen Panasonic M6 laminate mai sanye da jan karfe, tsara shimfidar allon allon da'ira daidai. Don manyan da'irori, gajarta hanyoyin sigina don rage tunanin sigina da tsangwama. Don manyan da'irar wutar lantarki, cikakken la'akari da al'amurran da suka shafi zubar da zafi, shirya abubuwan dumama, da tashoshi masu rarraba zafi yadda ya kamata don haɓaka yanayin zafi na laminate mai sanye da tagulla. Teamungiyar ƙirar mu ta fahimci kaddarorin laminate na Panasonic M6 kuma suna iya tsara ƙirar ƙira daidai da buƙatun kewaye daban-daban.

Ƙirƙirar Tari: Ƙirƙira tsarin tattara tarin allon da'irar bisa ƙayyadaddun da'irar da buƙatun aiki. Zaɓi adadin da ya dace na yadudduka, tsaka-tsakin tsaka-tsakin, da kayan rufewa don tabbatar da amincin sigina da kwanciyar hankali na aikin lantarki. Har ila yau, yi la'akari da canja wurin zafi da tasirin watsawa tsakanin yadudduka don kauce wa zafi na gida. Ta hanyar aiki mai yawa da ci gaba da ingantawa, mun haɓaka ingantaccen tsarin ƙira na kimiyya da ma'ana.

3. Sarrafa Tsarin Gudanarwa

Tsarin Etching: Daidaitaccen sarrafa sigogin etching don tabbatar da daidaito da ingancin alamun allon kewayawa. Zabi madaidaitan etchants da yanayin ƙugiya don guje wa wuce gona da iri ko ƙazafi. Bugu da ƙari, a kula da kariyar muhalli yayin aikin etching don hana gurɓata laminate ɗin da aka yi da jan karfe. Muna da ƙwararrun ƙwarewa a cikin matakan etching kuma muna iya sarrafa tsari daidai don tabbatar da ingancin hukumar kewayawa.

Tsarin Hakowa: Yi amfani da ingantaccen kayan aikin hakowa da sarrafa sigogin hakowa don tabbatar da girman rami da daidaiton matsayi. Ya kamata a yi taka tsantsan don guje wa lalata laminate ɗin da aka sanye da tagulla, wanda zai iya shafar aikin sa. Kayan aikin mu na hakowa da ƙwararrun ma'aikata suna tabbatar da daidaiton aikin hakowa.

Tsarin Lamination: Tsare-tsare ma'aunin lamination don tabbatar da mannewar interlayer da aikin lantarki. Zaɓi zafin lamination da ya dace, matsa lamba, da lokaci don tabbatar da haɗin gwiwa mai kyau tsakanin laminate da aka yi da jan karfe da sauran kayan rufewa. Har ila yau, kula da al'amurran da suka shafi shaye-shaye yayin aikin lamination don kauce wa kumfa da delamination. Mu stringent iko na lamination tsari yana tabbatar da barga aiki na kewaye hukumar.

4. Gwajin inganci da gyarawa

Gwajin Ayyukan Wutar Lantarki: Yi amfani da na'urorin gwaji na musamman don gwada kaddarorin lantarki na allon kewayawa, gami da juriya, ƙarfin aiki, inductance, juriya mai ƙarfi, da saurin watsa sigina. Tabbatar cewa aikin lantarki ya dace da buƙatun ƙira kuma ana amfani da ƙarancin wutar lantarki akai-akai da ƙarancin hasarar tangent na Panasonic M6 laminate na jan karfe. Na'urorin gwajinmu na ci gaba da haɓaka na iya gwada duk abubuwan da ke tattare da aikin lantarki na hukumar da'ira.

Gwajin Aiki na thermal: Yi amfani da na'urorin hoto masu zafi don saka idanu zafin aiki na hukumar da'ira da kuma duba tasirin watsar da zafi. Yi gwaje-gwajen girgiza zafin zafi don tantance daidaiton aikin hukumar da'ira a ƙarƙashin yanayin zafi daban-daban. Gwajin aikin mu mai tsauri yana tabbatar da kwanciyar hankali na hukumar kewayawa a wurare daban-daban na aiki.

Gyarawa da Haɓakawa: Bayan kammala ƙirar allon kewayawa, yi gyara da ingantawa. Daidaita sigogin kewayawa bisa sakamakon gwaji don inganta aiki da kwanciyar hankali na hukumar kewayawa. Bugu da ƙari, ci gaba da taƙaita gogewa da darussan da aka koya don ci gaba da haɓaka hanyoyin masana'antu da ƙirar ƙira don mafi kyawun amfani da fa'idodin Panasonic M6 laminate tagulla. Ƙungiyar mu na gyarawa da haɓakawa na iya hanzarta aiwatar da gyara kurakurai don ci gaba da haɓaka ingancin samfur.

A taƙaice, tare da ɗimbin ƙwarewar samarwa da zurfin fahimtar Panasonic M6 kayan laminate na jan karfe, muna da kwarin gwiwa wajen samarwa abokan cinikinmu samfuran PCB masu inganci.