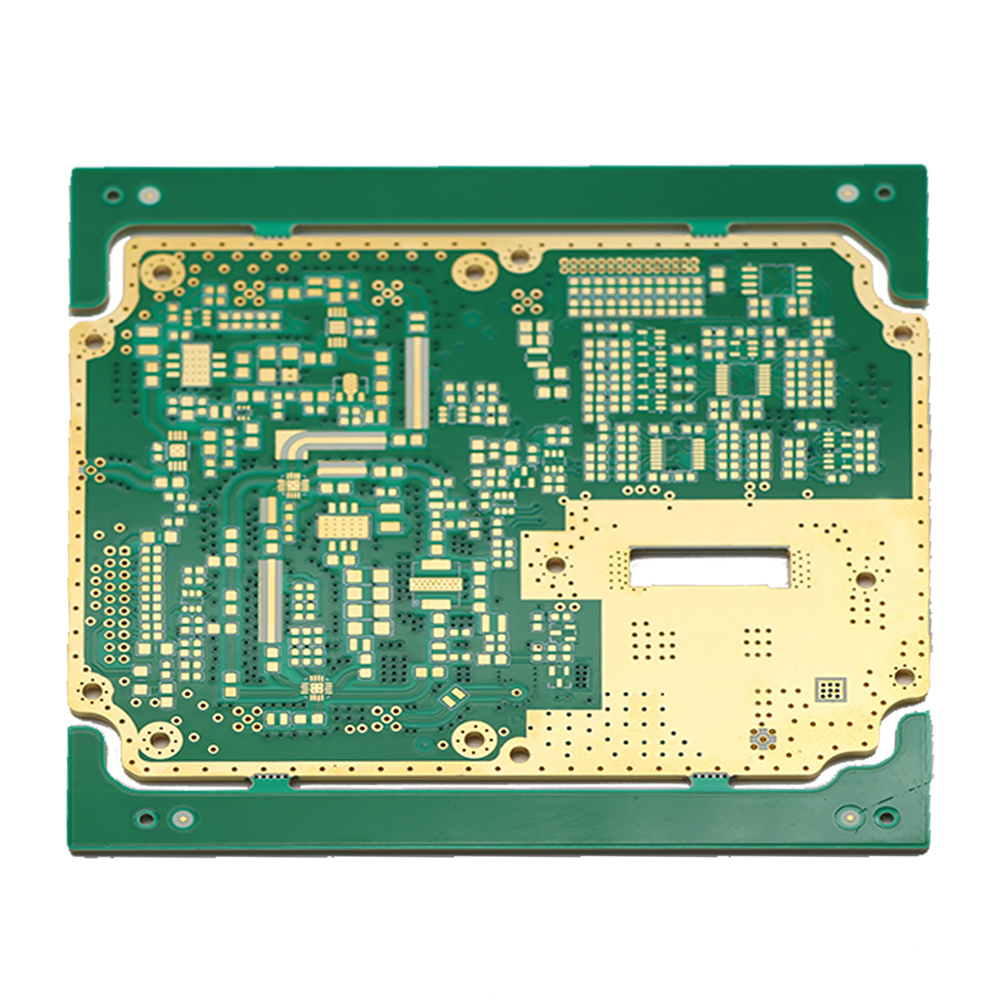

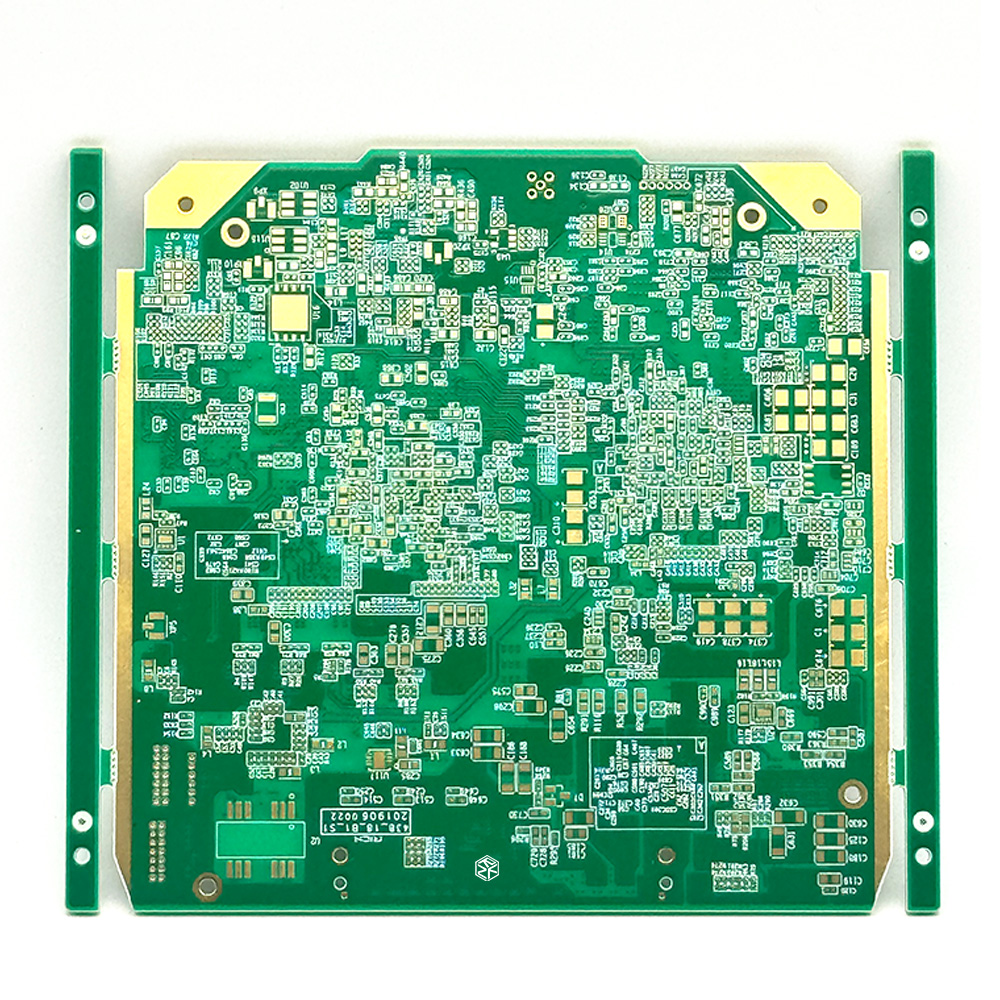

Optical Module HDI PCB Optical Module Kub ntiv tes PCB

Cov lus qhia kev tsim khoom

| Hom | ob txheej HDI, impedance, resin plug qhov |

| Teeb meem | Panasonic M6 Copper-Clad Laminate |

| Tus naj npawb ntawm txheej | 10 L |

| Board Thickness | 1.2 hli |

| Ib leeg loj | 150 * 120 hli / 1SET |

| Nto tiav | PRINCIPAL |

| Sab hauv tooj liab thickness | 18 awm |

| Sab nrauv tooj liab thickness | 18 awm |

| Xim ntawm daim npog ntsej muag | ntsuab (GTS, GBS) |

| Silkscreen xim | dawb (GTO, GBO) |

| Ntawm kev kho mob | 0.2 hli |

| Qhov ceev ntawm mechanical drilling qhov | 16W / ㎡ |

| Qhov ceev ntawm laser drilling qhov | 100W / ㎡ |

| Min ntawm qhov loj me | 0.1 hli |

| Min kab dav / qhov chaw | 3/3 mil |

| Aperture ratio | 9mil ua |

| Nias lub sij hawm | 3 xee |

| Lub sijhawm drilling | 5 lub sijhawm |

| PN | E240902A |

Cov ntsiab lus tseem ceeb hauv kev tsim cov Optical Module HDI Kub ntiv tes PCBs

- 1, Precision Etching Control Cov xov hlau ntawm cov ntiv tes kub thiab HDI PCBs yog qhov nyuaj heev, ua rau kev tswj cov txheej txheem etching tseem ceeb tshwj xeeb. Tsis zoo etching tuaj yeem ua rau cov kab tsis sib xws, luv luv, lossis qhib circuits. Yog li ntawd, yuav tsum tau siv high-precision etching khoom, thiab calibration tsis tu ncua yog tsim nyog los xyuas kom meej qhov tseeb thiab sib xws nyob rau hauv cov txheej txheem etching.

3 、 Lamination Txheej Txheem Tswj Lamination yog ib kauj ruam tseem ceeb uas ntau txheej txheej PCB raug nias ua ke. Kev tswj qhov kub, siab, thiab lub sij hawm thaum lub sij hawm lamination yog ib qho tseem ceeb los xyuas kom meej qhov ruaj khov ntawm cov khaubncaws sab nraud povtseg thiab uniform board thickness. Cov lamination tsis zoo tuaj yeem ua rau delamination lossis voids, cuam tshuam rau ob qho tib si hluav taws xob kev ua haujlwm thiab lub zog txhua yam.

4 、 Kub ntiv tes Plating Thickness Tswj Lub thickness ntawm cov kub plating ntawm cov ntiv tes kub ncaj qha cuam tshuam rau lub neej thiab kev sib cuag. Yog hais tias kub plating yog nyias, nws yuav hnav sai sai; yog tuab heev, nws nce nqi. Yog li ntawd, thaum lub sij hawm plating txheej txheem, kub plating lub sij hawm thiab tam sim no ceev yuav tsum tau nruj me ntsis tswj kom lub plating thickness raws li cov qauv (feem ntau 30-50 microinches).

5、Impedance Control thiab Test Optical module HDI PCBs feem ntau tuav cov teeb liab ceev, ua rau impedance tswj tseem ceeb heev. Thaum lub sijhawm tsim khoom, cov khoom siv ntsuas impedance yuav tsum tau siv los saib xyuas thiab ntsuas cov cim tseem ceeb hauv lub sijhawm tiag tiag, kom ntseeg tau tias qhov impedance nyob rau hauv qhov tsim ntau yam (xws li, 100 ohms). Tsis ua raws li impedance tuaj yeem ua rau muaj teeb meem kev ncaj ncees, xws li kev xav thiab kev sib tham.

6.Soldering Quality Control Vim muaj qhov ntom ntom ntawm cov khoom siv hauv cov khoom siv kho qhov muag PCBs, cov txheej txheem soldering yuav tsum yog qhov tseeb. Advanced reflow soldering thiab yoj soldering cov cuab yeej yuav tsum tau, thiab soldering kub profiles yuav tsum tau nruj me ntsis tswj los xyuas kom meej lub robustness ntawm solder pob qij txha thiab kev ntseeg siab ntawm hluav taws xob kev twb kev txuas.

7, Kev Tu Nto thiab Kev Tiv Thaiv Nyob rau txhua theem ntawm kev tsim khoom, PCB nto yuav tsum tau ua kom huv si kom tsis txhob muaj plua plav, ntiv tes, lossis oxidation residues. Cov kab mob no tuaj yeem ua rau hluav taws xob luv lossis cuam tshuam rau qhov zoo ntawm cov plating. Tom qab kev tsim khoom, cov txheej txheem tiv thaiv tsim nyog yuav tsum tau siv los tiv thaiv kev ya raws thiab cov kab mob los ntawm kev nkag mus.

8 、 Kev Tshuaj Xyuas Zoo thiab Kev Tshawb Fawb Kev Tshawb Fawb Kev Tshawb Fawb Kev Tshawb Fawb, suav nrog kev tshuaj xyuas qhov muag, kuaj hluav taws xob, thiab kev sim ua haujlwm, yog qhov tseem ceeb. Cov kev tshuaj ntsuam xyuas feem ntau suav nrog Kev Tshawb Fawb Kev Siv Hluav Taws Xob (AOI), kev sojntsuam ya, thiab X-ray tshuaj xyuas kom ntseeg tau tias txhua PCB ua tau raws li cov qauv tsim thiab cov qauv zoo.

Qhov tseem ceeb ntawm Routing hauv Optical Module HDI PCBs

- Dimensions thiab Spacing: Qhov dav thiab qhov sib nrug ntawm cov ntiv tes kub yuav tsum tau tswj nruj me ntsis kom ntseeg tau tias qhov zoo meej haum nrog cov khoom sib txuas. Feem ntau, qhov dav ntawm cov ntiv tes kub yog 0.5 hli, nrog qhov sib nrug ntawm 0.5 hli.

- Ntug Chamfering: Chamfering feem ntau yuav tsum tau nyob rau ntawm cov npoo ntawm PCB qhov twg cov ntiv tes kub nyob rau hauv kev pab txhawb smoother ntxig rau hauv cov qhov.

Txheej suav thiab stacking: HDI PCBs feem ntau suav nrog ntau txheej txheej tsim los muab kev xaiv hluav taws xob txuas ntxiv. Cov txheej suav thiab stacking tsim yuav tsum tau txiav txim siab los xyuas kom meej ob qho tib si teeb liab kev ncaj ncees thiab lub zog ncaj ncees.

Microvias: Siv cov tshuab microvia, xws li qhov muag tsis pom thiab faus vias, tuaj yeem txo qhov ntev ntawm kev sib txuas ntawm interlayer, yog li txo cov teeb liab qeeb thiab poob. Cov microvias no xav tau kev tswj xyuas meej ntawm lawv txoj haujlwm thiab qhov ntev.

Routing Density: Vim yog qhov siab ceev ntawm HDI boards, tshwj xeeb yuav tsum tau them rau qhov dav thiab qhov sib txawv ntawm cov kab. Feem ntau, kab dav dav yog 3-4 mil, thiab qhov sib txawv kuj yog 3-4 mil.

3.Teeb liab kev ncaj ncees

Differential Pair Routing: High-ceev teeb liab kis tau tus mob feem ntau siv nyob rau hauv optical modules yuav tsum tau sib txawv khub routing los txo electromagnetic cuam tshuam thiab teeb liab xav. Qhov ntev thiab qhov sib txawv ntawm cov khub sib txawv yuav tsum sib phim, kom ntseeg tau tias kev tswj hwm impedance nyob rau hauv qhov tsim nyog (piv txwv li, 100 ohms).

Impedance Control: Nyob rau hauv high-ceev teeb liab routing, nruj impedance tswj yog qhov tseem ceeb. Kev sib txuam impedance tuaj yeem ua tiav los ntawm kev kho qhov dav dav, qhov sib nrug, thiab txheej txheej txheej.

Ntawm Kev Siv: Kev siv cov vias yuav tsum raug txo kom tsawg, raws li lawv qhia cov kab mob parasitic capacitance thiab inductance, cuam tshuam cov teeb liab zoo. Thaum tsim nyog, tsim nyog ntawm hom (xws li qhov muag tsis pom thiab faus vias) thiab qhov chaw yuav tsum tau xaiv.

Decoupling Capacitors: Kev tso cai ntawm decoupling capacitors pab tswj lub zog hluav taws xob thiab txo lub suab nrov.

Fais fab Plane Design: Txais cov khoom siv fais fab dav hlau tsim kom muaj kev sib faib tam sim no thiab txo cov kev cuam tshuam hluav taws xob (EMI).

Kev Tswj Thermal: Txij li cov khoom siv kho qhov muag ua kom muaj cua sov thaum lub sijhawm ua haujlwm, cov kev tswj xyuas thermal yuav tsum raug txiav txim siab hauv kev tsim, xws li siv cov khoom siv thermal, cov khoom siv hluav taws xob, lossis cov dab dej kub los txhim kho cov cua sov kom zoo.

6.Kev xaiv khoom

Cov khoom siv substrate: Xaiv cov substrates uas haum rau cov ntawv thov ntau zaus, xws li polyimide (PI) lossis fluoropolymer, kom ntseeg tau tias cov teeb liab kis tau zoo thiab ruaj khov.

Solder Mask: Siv cov khoom siv kub-kub, tsis tshua muaj cov khoom siv los tiv thaiv cov kab thiab hluav taws xob.

Kub ntiv tes HDI PCBs tau siv dav hauv ntau qhov chaw vim lawv qhov ceev thiab cov yam ntxwv ua haujlwm siab:

5 、 Cov Khoom Siv Kho Mob: Hauv cov khoom siv kho mob xav tau zoo li CT scanners, MRI tshuab, thiab lwm yam cuab yeej kuaj mob, cov ntiv tes kub HDI PCBs ua kom cov ntaub ntawv raug xa mus thiab txhim khu kev lag luam ntawm cov cuab yeej.

- 6, Aerospace: Cov PCBs no tau siv rau hauv kev tswj hwm ntawm satellites, aircraft, thiab spacecraft, raws li lawv tuaj yeem tiv taus ib puag ncig hnyav thaum tswj kev ua haujlwm siab.

- 7 、 Kev Tswj Xyuas Kev Lag Luam: Hauv kev lag luam automation, PLCs (Programmable Logic Controllers), thiab cov neeg hlau muaj, cov ntiv tes kub HDI PCBs muab kev tswj xyuas kev ntseeg siab thiab cov teeb liab kis tau tus mob.

Kub ntiv tes

Kev Taw Qhia Kom Paub Txog Cov Ntiv Kub Kub

Cov ntiv tes kub xa mus rau thaj chaw kub-plated ntawm ntug ntawm lub rooj tsav xwm luam tawm (PCB). Lawv feem ntau yog siv los ua hluav taws xob sib txuas nrog cov khoom sib txuas. Lub npe "gold finger" los ntawm lawv cov tsos: cov sawb zoo li kub-plated seem zoo li cov ntiv tes. Cov ntiv tes kub feem ntau yog siv rau hauv cov khoom siv PCBs, xws li cov cim nco, cov ntawv teev lus, thiab lwm yam khoom siv, los txuas nrog cov slots. Lub luag haujlwm tseem ceeb ntawm cov ntiv tes kub yog muab kev sib txuas hluav taws xob txhim khu kev qha los ntawm cov txheej txheem kub kub plating thaum ua kom ntseeg tau hnav tsis kam thiab corrosion kuj.

Kev faib cov ntiv tes kub

Cov ntiv tes kub tuaj yeem raug cais raws li lawv txoj haujlwm, txoj haujlwm, thiab cov txheej txheem tsim khoom:

Hluav taws xob txuas Kub ntiv tes: Cov ntiv tes kub no tsuas yog siv los muab kev sib txuas hluav taws xob ruaj khov, xws li hauv ncoo, daim npav kos duab, thiab lwm yam khoom siv plug-in. Lawv xa cov teeb liab hluav taws xob los ntawm kev muab tso rau hauv qhov chaw ntawm lub motherboard lossis lwm yam khoom siv.

Lub Hwj Chim Kub Kub: Cov no yog siv los muab lub zog lossis kev sib txuas hauv av, kom ntseeg tau tias cov khoom siv tau txais cov khoom siv hluav taws xob ruaj khov.

2.Raws li Txoj Haujlwm:

Ntug Kub ntiv tes: Feem ntau nyob ntawm ntug ntawm PCB, lawv tau siv rau kev sib txuas ntawm qhov sib txuas thiab feem ntau pom muaj nyob hauv cov cim xeeb, cov ntawv teev lus, thiab cov qauv sib txuas lus. Qhov no yog hom kub ntiv tes tshaj plaws.

Non-Edge Gold Fingers: Cov ntiv tes kub no tsis nyob ntawm ntug ntawm PCB tab sis tau muab tso rau sab hauv rau cov kev sib txuas tshwj xeeb lossis kev ua haujlwm, xws li cov ntsiab lus ntsuas lossis kev sib txuas hauv module.

3.Raws li Manufacturing Process:

Immersion Gold Fingers: Cov no yog tsim los siv cov txheej txheem chemical deposition los siv ib txheej kub rau ntawm daim ntawv tooj liab. Lawv muaj ib tug du, zoo nto, tab sis ib tug nyias txheej txheej, feem ntau yog siv rau qis zaus hluav taws xob sib txuas.

Electroplated Kub ntiv tes: Ua los ntawm cov txheej txheem electroplating, cov ntiv tes kub no muaj cov txheej kub tuab dua thiab hnav-tiv taus ntau dua, haum rau cov khoom siv hluav taws xob uas muaj kev ntseeg siab uas yuav tsum tau ntxig thiab tshem tawm ntau zaus, xws li hauv cov ntawv cim xeeb thiab cov ntawv teev lus. Cov txheej txheem no feem ntau siv cov txheej kub txheej tuab ntawm 30-50 microinches los xyuas kom meej durability thiab zoo conductivity.

4.Raws li txoj kev sib txuas:

Ncaj Ntiv Ntiv Kub Ntiv Nplhaib: Tso ncaj qha rau hauv lub qhov, qhov qhov elasticity tuav cov ntiv tes kub. Txoj kev no yog dav siv hauv nco sticks thiab graphics phaib.

Latch Kub ntiv tes: Txuas siv latches lossis lwm yam khoom siv fastening, muab cov khoom siv kho kom zoo ntxiv, feem ntau siv rau cov qauv loj thiab cov ntawv thov uas xav tau kev sib txuas ruaj khov dua.

Daim ntawv thov yam ntxwv ntawm tus ntiv tes kub

- High Conductivity thiab Stability: Cov khoom tseem ceeb ntawm cov ntiv tes kub yog kub plating, uas muaj cov conductivity zoo heev thiab ruaj khov, muab kev ua haujlwm zoo tshaj plaws.

- Hnav Resistance: Cov ntawv thov uas nquag ntxig thiab tshem tawm yuav tsum tau ntiv tes kub kom muaj kev hnav zoo. Cov txheej kub plating muaj qhov kev tiv thaiv no, kom ntseeg tau tias cov ntiv tes kub tsis hnav lossis oxidize yooj yim thaum siv.

- Corrosion Resistance: Cov txheej kub plating ntawm cov ntiv tes kub tsis yog tsuas yog muab cov khoom siv hluav taws xob xwb tab sis kuj tiv thaiv cov khoom corrosive nyob rau hauv ib puag ncig, ncua lub neej ntawm cov ntiv tes kub.

Classification ntawm Optical Modules

1.Raws li kev sib kis ceev:

10G Optical Modules: Siv rau 10 Gigabit Ethernet daim ntawv thov.

25G Optical Modules: Tsim rau 25 Gigabit Ethernet.

40G Optical Modules: Siv hauv 40 Gigabit Ethernet tes hauj lwm.

100G Optical Modules: Haum rau 100 Gigabit Ethernet tes hauj lwm.

400G Optical Modules: Rau ultra-high-speed 400 Gigabit Ethernet daim ntaub ntawv.

2.Raws li Kev Tshaj Tawm Tshaj Tawm:

Short-Range Optical Modules (SR): Feem ntau txhawb kev ncua mus txog 300 meters siv multimode fiber (MMF).

Ntev-Range Optical Modules (LR): Tsim los rau kev ncua mus txog 10 kilometers siv ib hom fiber ntau (SMF).

Extended Range Optical Modules (ER): tuaj yeem xa mus txog 40 mais hla SMF.

Ntev-Range Optical Modules (ZR): Kev them nyiaj yug nrug ntau dua 80 mais ntawm SMF.

3.Raws li Wavelength:

850nm Modules: Feem ntau siv rau luv luv kis tau tus mob hla multimode fiber ntau.

1310nm Modules: Haum rau nruab nrab-ntau kis tau tus mob tshaj ib hom fiber ntau.

1550nm Modules: Siv rau kev sib kis ntev, tshwj xeeb tshaj yog ib hom fiber ntau.

4.Raws li Form Factor:

SFP (Small Form-Factor Pluggable): Feem ntau siv rau 1G thiab 10G tes hauj lwm.

SFP + (Enhanced Small Form-Factor Pluggable): Siv rau 10G tes hauj lwm nrog kev ua tau zoo dua.

QSFP (Quad Small Form-Factor Pluggable): Haum rau 40G daim ntawv thov.

QSFP28: Tsim los rau 100G tes hauj lwm, muab kev daws teeb meem ntau dua.

CFP (C Form-Factor Pluggable): Siv hauv 100G thiab 400G daim ntawv thov, loj dua SFP / QSFP modules.

5.Raws li Daim Ntawv Thov:

Data Center Optical Modules: Tsim los rau kev xa cov ntaub ntawv ceev ceev hauv cov chaw zov me nyuam.

Telecom Optical Modules: Siv hauv kev sib txuas lus hauv kev sib txuas lus rau kev xa cov ntaub ntawv mus ntev.

Industrial Optical Modules: Ua rau thaj chaw rugged, nrog kev ua haujlwm siab kub hloov pauv thiab cuam tshuam electromagnetic.

Yuav ua li cas paub qhov txawv HDI Kauj Ruam suav

faus Vias: Cov qhov embedded nyob rau hauv lub rooj tsavxwm, tsis pom los ntawm sab nraud.

Qhov muag tsis pom kev: Qhov qhov uas pom sab nraud tab sis tsis pom-dhau.

Qib suav: Tus naj npawb ntawm ntau hom kev dig muag vias, raws li pom los ntawm ib qho kawg ntawm lub rooj tsavxwm, tuaj yeem txhais tau tias yog cov kauj ruam suav.

Lamination suav: Tus naj npawb ntawm lub sij hawm qhov muag tsis pom / faus vias dhau los ntawm ntau lub cores lossis dielectric txheej.

PCB yog tsim los ntawm Panasonic M6 tooj liab-clad laminate

PCB yog tsim los ntawm Panasonic M6 tooj liab-clad laminate. Peb muaj kev paub dhau los hauv daim teb no thiab paub yuav ua li cas thiaj li siv tau qhov kev ua tau zoo ntawm Panasonic M6 cov ntaub ntawv los ntawm kev tsom mus rau thaj chaw hauv qab no:

1. Kev xaiv thiab tshuaj xyuas cov khoom

Kev xaiv tus neeg siv khoom nruj: Xaiv lub npe nrov thiab txhim khu kev qha Panasonic M6 tooj liab-clad laminate lwm tus neeg los xyuas kom meej cov khoom ruaj khov thiab cov qauv ua raws. Qhov no tuaj yeem ua tiav los ntawm kev ntsuas tus neeg xa khoom tsim nyog, muaj peev xwm tsim khoom, thiab kev tswj xyuas zoo. Peb lub xyoo dhau los tau ua rau peb tsim kom muaj kev sib koom tes ntev, ruaj khov nrog cov neeg muag khoom zoo, ua kom cov khoom zoo los ntawm qhov chaw.

Kev tshuaj xyuas cov khoom: Thaum tau txais cov khoom siv tooj liab-clad, ua cov kev tshuaj xyuas nruj heev los xyuas qhov tsis xws luag xws li kev puas tsuaj lossis stains thiab ntsuas qhov tsis xws li tuab thiab qhov ntev kom ntseeg tau tias lawv ua tau raws li qhov yuav tsum tau ua. Cov cuab yeej kuaj tshwj xeeb kuj tuaj yeem siv los ntsuas cov khoom siv hluav taws xob, thermal conductivity, thiab lwm yam ntsuas kev ua haujlwm kom ntseeg tau tias lawv ua tau raws li cov qauv tsim. Peb pab neeg soj ntsuam kev tshaj lij siv cov cuab yeej siv siab heev thiab cov txheej txheem nruj kom ntseeg tau tias tsis muaj kev nthuav dav.

2. Kev tsim kho kom zoo

Circuit layout Design: Raws li cov yam ntxwv ntawm Panasonic M6 tooj liab-clad laminate, tsim lub Circuit Court board layout kom tsim nyog. Rau high-frequency circuits, shorten teeb liab txoj kev los txo cov teeb liab xav txog thiab cuam tshuam. Rau high-power circuits, tag nrho xav txog cov teeb meem kub dissipation, npaj cov khoom cua sov, thiab cov cua kub dissipation raws kom zoo tshaj plaws thermal conductivity ntawm tooj liab-clad laminate. Peb pab neeg tsim khoom nkag siab txog cov khoom ntawm Panasonic M6 laminate thiab tuaj yeem tsim cov qauv tsim raws li ntau yam kev xav tau hauv Circuit Court.

Stack-Up Design: Optimize lub Circuit Court board lub stack-up qauv raws li Circuit Court complexity thiab kev ua tau zoo yuav tsum tau. Xaiv qhov tsim nyog tus naj npawb ntawm cov khaubncaws sab nraud povtseg, interlayer spacing, thiab rwb thaiv tsev cov ntaub ntawv los xyuas kom meej lub teeb liab thiab hluav taws xob kev ua tau zoo stability. Tsis tas li, xav txog kev hloov hluav taws xob thiab kev cuam tshuam ntawm cov txheej txheem kom tsis txhob muaj cua sov hauv zos. Los ntawm kev xyaum dav dav thiab kev ua kom zoo tsis tu ncua, peb tau tsim ib qho kev tshawb fawb thiab tsim nyog tsim kev daws teeb meem.

3. Kev tswj cov txheej txheem tsim khoom

Etching txheej txheem: Muaj tseeb tswj etching tsis kom ntseeg tau qhov tseeb thiab zoo ntawm lub rooj tsav xwm Circuit Court cov kab. Xaiv cov etchants tsim nyog thiab etching tej yam kev mob kom tsis txhob over-etching los yog under-etching. Tsis tas li ntawd, nco ntsoov txog kev tiv thaiv ib puag ncig thaum lub sij hawm etching txheej txheem los tiv thaiv kev sib kis ntawm tooj liab-clad laminate. Peb muaj kev nplua nuj nyob rau hauv cov txheej txheem etching thiab tuaj yeem tswj cov txheej txheem kom ntseeg tau tias qhov zoo ntawm lub rooj tsavxwm.

Cov txheej txheem Drilling: Siv cov cuab yeej ua haujlwm siab zoo drilling thiab tswj qhov ntsuas qhov ntsuas kom paub meej lub qhov loj thiab qhov chaw raug. Kev saib xyuas yuav tsum tau ua kom tsis txhob ua kom puas lub copper-clad laminate, uas yuav cuam tshuam rau nws cov kev ua tau zoo. Peb cov cuab yeej drilling siab heev thiab cov neeg ua haujlwm txawj ua kom ntseeg tau qhov tseeb ntawm cov txheej txheem drilling.

Txheej txheem lamination: nruj me ntsis tswj cov txheej txheem lamination kom paub meej interlayer adhesion thiab hluav taws xob ua haujlwm. Xaiv qhov tsim nyog lamination kub, siab, thiab lub sij hawm los xyuas kom meej kev sib raug zoo ntawm cov tooj liab-clad laminate thiab lwm yam ntaub ntawv insulating. Tsis tas li ntawd, xyuam xim rau cov teeb meem tso tawm thaum lub sij hawm lamination txheej txheem kom tsis txhob muaj npuas thiab delamination. Peb txoj kev tswj hwm nruj ntawm cov txheej txheem lamination ua kom ruaj khov kev ua haujlwm ntawm lub rooj tsav xwm Circuit Court.

4. Kev soj ntsuam zoo thiab kev debugging

Kev Ntsuas Hluav Taws Xob: Siv cov cuab yeej ntsuas tshwj xeeb los ntsuas cov khoom hluav taws xob ntawm lub rooj tsav xwm hauv Circuit Court, suav nrog kev ua haujlwm, kev muaj peev xwm, inductance, rwb thaiv tsev tsis kam, thiab teeb liab kis ceev. Xyuas kom meej tias cov hluav taws xob ua tau raws li qhov yuav tsum tau ua thiab qhov tsis tshua muaj dielectric tsis tu ncua thiab qis dielectric poob tangent yam ntxwv ntawm Panasonic M6 tooj liab-clad laminate yog siv tag nrho. Peb cov cuab yeej ntsuas qib siab thiab muaj peev xwm tuaj yeem kuaj txhua yam ntawm lub rooj tsav xwm hluav taws xob ua haujlwm hluav taws xob.

Thermal Performance Testing: Siv cov cuab yeej ntsuas cua sov los saib xyuas qhov ua haujlwm kub ntawm lub rooj tsavxwm Circuit Court thiab xyuas qhov ua tau zoo ntawm cov cua kub dissipation. Ua cov kev ntsuam xyuas thermal shock los ntsuas qhov kev ruaj ntseg ntawm lub rooj tsav xwm hauv Circuit Court kev ua haujlwm nyob rau hauv qhov sib txawv ntawm qhov kub thiab txias. Peb qhov kev ntsuam xyuas thermal ua tau zoo ua kom muaj kev ruaj ntseg ntawm lub rooj tsav xwm hauv Circuit Court hauv ntau qhov chaw ua haujlwm.

Debugging thiab Optimization: Tom qab ua tiav cov khoom siv hluav taws xob hauv Circuit Court, ua kev debugging thiab optimization. Kho qhov ntsuas hluav taws xob raws li qhov ntsuas tau los txhim kho kev ua haujlwm thiab kev ruaj ntseg ntawm lub rooj tsav xwm Circuit Court. Tsis tas li ntawd, tas li sau cov kev paub dhau los thiab cov lus qhia uas tau kawm los txuas ntxiv txhim kho cov txheej txheem tsim khoom thiab tsim cov kev daws teeb meem kom zoo dua siv qhov zoo ntawm Panasonic M6 tooj liab-clad laminate. Peb pab neeg debugging thiab optimization tuaj yeem sai thiab raug ua tiav debugging kom txuas ntxiv txhim kho cov khoom zoo.

Hauv cov ntsiab lus, nrog peb cov kev paub ntau lawm thiab kev nkag siab tob ntawm Panasonic M6 tooj liab-clad laminate cov ntaub ntawv, peb ntseeg siab muab peb cov neeg siv khoom nrog cov khoom zoo PCB.