PCB nto tiav

| Nto tiav | Tus nqi | Tus neeg muab khoom |

| Volunteer Fire Department | 0.3 ~ 0.55um, 0.25 ~ 0.35um | Enthone |

| Shikoku tshuaj | ||

| Pom zoo | Los yog: 0.03 ~ 0.12um, Ni: 2.5 ~ 5um | ATO tech/Chuang Zhi |

| Selective ENIG | Los yog: 0.03 ~ 0.12um, Ni: 2.5 ~ 5um | ATO tech/Chuang Zhi |

| PRINCIPAL | Au: 0.05 ~ 0.125um, Pd: 0.05 ~ 0.3um, | Chuang Zhi |

| Hauv: 3 ~ 10um | ||

| Hard kub | Au: 0.127 ~ 1.5um, Ni : min 2.5um | Payer/EEJA |

| Mos Kub | Au: 0.127 ~ 0.5um, Ni : min 2.5um | EJA |

| Immersion Tin | Min: 1 um | Enthone / ATO Tech |

| Immersion Nyiaj | 0.127 ~ 0.45 hli | Macdermid |

| Lead dawb HASL | 1 ~ 25 hli | Nihon Superior |

Vim lub fact tias tooj liab muaj nyob rau hauv daim ntawv ntawm oxides nyob rau hauv cov huab cua, nws cuam tshuam rau solderability thiab hluav taws xob kev ua tau zoo ntawm PCBs. Yog li ntawd, nws yog ib qho tsim nyog yuav tsum ua kom tiav qhov kawg ntawm PCBs. Yog tias qhov chaw ntawm PCBs tsis tiav, nws yog ib qho yooj yim los ua cov teeb meem virtual soldering, thiab nyob rau hauv cov xwm txheej hnyav, cov ntaub qhwv thiab cov khoom siv tsis tuaj yeem soldered. PCB nto tiav yog hais txog cov txheej txheem ntawm kev tsim cov txheej txheem saum npoo ntawm PCB. Lub hom phiaj ntawm PCB tiav yog los xyuas kom meej tias PCB muaj kev ua haujlwm zoo lossis hluav taws xob ua haujlwm. Muaj ntau hom kev ua tiav rau PCBs.

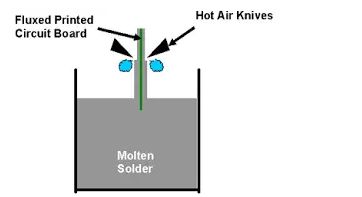

Cua kub Solder Leveling (HASL)

Nws yog txheej txheem ntawm kev siv cov molten tin lead solder rau ntawm qhov chaw ntawm PCB, flattening (tshuab) nws nrog cua sov compressed cua thiab tsim ib txheej txheej uas yog ob qho tib si tiv taus tooj liab oxidation thiab muab zoo solderability. Thaum lub sij hawm tus txheej txheem no, nws yog ib qho tsim nyog yuav tau ua raws li qhov tseem ceeb hauv qab no: soldering kub, cua kub riam kub, cua kub riam siab, immersion lub sij hawm, lifting ceev, thiab lwm yam.

Qhov zoo ntawm HASL

1. Lub sijhawm khaws cia ntev dua.

2. Cov ntaub qhwv zoo ntub dej thiab npog tooj liab.

3. Siv dav siv lead ua dawb (RoHS raws) hom.

4. Cov cuab yeej technology, tus nqi qis.

5. Zoo heev rau kev kuaj pom thiab kuaj hluav taws xob.

Tsis muaj zog ntawm HASL

1. Tsis haum rau kev sib txuas xov hlau.

2. Vim lub ntuj meniscus ntawm molten solder, lub flatness tsis zoo.

3. Tsis siv rau capacitive kov keyboards.

4. Rau cov vaj huam sib luag tshwj xeeb, HASL yuav tsis haum. Qhov kub ntawm lub da dej yuav ua rau lub rooj tsav xwm Circuit Court warp.

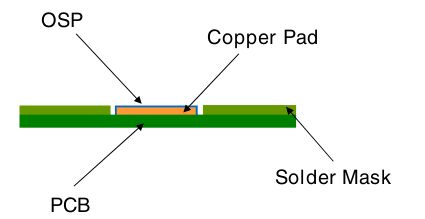

2. Lub Chaw Haujlwm Pabcuam Hluav Taws Xob

OSP yog lub npe luv rau Organic Solderability Preservative, tseem hu ua ib qho solder. Nyob rau hauv luv luv, OSP yog hais tias yuav tsum tau txau rau saum npoo ntawm tooj liab solder pads los muab ib tug tiv thaiv zaj duab xis ua los ntawm cov organic tshuaj. Cov yeeb yaj kiab no yuav tsum muaj cov khoom xws li oxidation tsis kam, thermal shock resistance thiab ya raws los tiv thaiv tooj liab nto los ntawm xeb (oxidation los yog vulcanization, thiab lwm yam) nyob rau hauv ib puag ncig ib puag ncig. Txawm li cas los xij, nyob rau hauv lub tom ntej kub-kub soldering, qhov kev tiv thaiv zaj duab xis yuav tsum tau yooj yim tshem tawm los ntawm cov flux sai, yog li hais tias cov ntaub so ntswg tooj liab tuaj yeem tam sim ntawd nrog cov melted solder los ua ib qho kev sib koom ua ke hauv lub sijhawm luv luv. Hauv lwm lo lus, lub luag haujlwm ntawm OSP yog los ua qhov thaiv ntawm tooj liab thiab huab cua.

Qhov zoo ntawm OSP

1. Yooj yim thiab pheej yig; Qhov saum npoo tiav tsuas yog txau txheej.

2. Qhov saum npoo ntawm cov ntaub so ntswg yog du heev, nrog ib tug flatness piv rau ENIG.

3. Ua kom dawb (ua raws li RoHS cov qauv) thiab tus phooj ywg ib puag ncig.

4. Reworkable.

Tsis muaj zog ntawm OSP

1. Cov dej tsis zoo.

2. Qhov tseeb thiab nyias nyias ntawm zaj duab xis txhais tau hais tias nws yog qhov nyuaj rau kev ntsuas qhov zoo los ntawm kev tshuaj xyuas qhov muag thiab ua kev sim online.

3. Lub neej ua haujlwm luv luv, kev xav tau siab rau kev khaws cia thiab tuav.

4. Kev tiv thaiv tsis zoo rau plated los ntawm qhov.

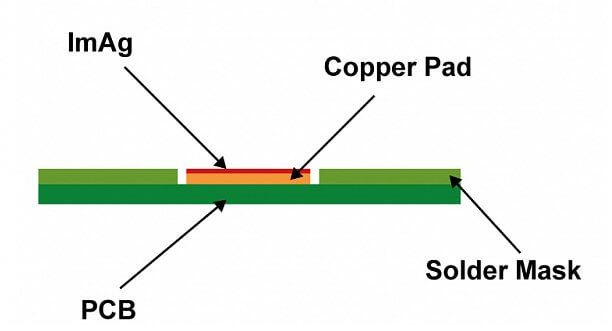

Immersion Nyiaj

Silver muaj cov tshuaj lom neeg ruaj khov. Lub PCB ua tiav los ntawm cov nyiaj immersion thev naus laus zis tseem tuaj yeem muab hluav taws xob ua haujlwm tau zoo txawm tias raug kub hnyiab, qhov chaw ntub dej thiab muaj kuab paug, nrog rau kev tswj xyuas kom zoo txawm tias nws yuav poob nws cov luster. Immersion Silver yog ib qho kev hloov pauv hloov qhov twg ib txheej ntawm cov nyiaj ntshiab yog tso ncaj qha rau ntawm tooj liab. Qee zaum, cov nyiaj immersion yog ua ke nrog OSP txheej los tiv thaiv cov nyiaj los ntawm kev ua haujlwm nrog sulfides hauv ib puag ncig.

Qhov zoo ntawm Immersion Silver

1. Siab solderability.

2. Zoo nto flatness.

3. Tus nqi qis thiab tsis muaj txhuas (ua raws li RoHS cov qauv).

4. Muaj feem xyuam rau Al hlau sib txuas.

Tsis muaj zog ntawm Immersion Silver

1. Kev cia siab siab thiab yooj yim kom muaj kuab paug.

2. Lub sij hawm luv luv lub qhov rais tom qab tshem tawm ntawm lub ntim.

3. Tsis yooj yim rau kev kuaj hluav taws xob.

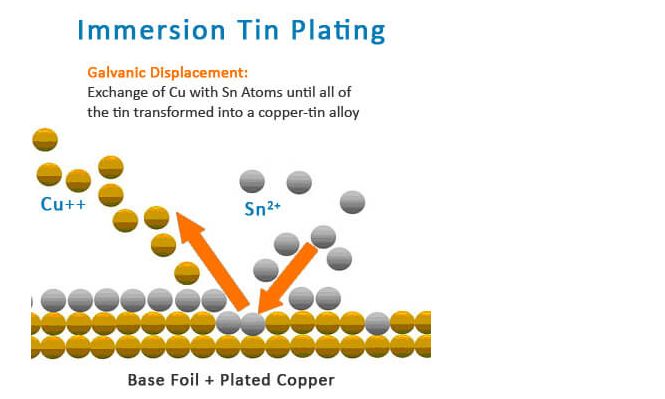

Immersion Tin

Txij li thaum tag nrho cov solder yog tin raws li, lub tin txheej tuaj yeem phim txhua hom solder. Tom qab ntxiv cov organic additives rau tin immersion tov, tin txheej qauv nthuav tawm cov qauv granular, kov yeej cov teeb meem tshwm sim los ntawm tin whiskers thiab tin migration, thaum tseem muaj thermal stability thiab solderability.

Cov txheej txheem Immersion Tin tuaj yeem tsim cov tooj liab tin intermetallic sib txuas ua kom cov immersion tin muaj qhov zoo solderability yam tsis muaj flatness lossis intermetallic compound diffusion teeb meem.

Qhov zoo ntawm Immersion Tin

1. Muaj feem xyuam rau kab rov tav ntau lawm.

2. Muaj feem xyuam rau kev ua cov hlau zoo thiab tsis muaj cov hlau lead, tshwj xeeb tshaj yog siv rau cov txheej txheem crimping.

3. Lub flatness yog zoo heev, muaj feem xyuam rau SMT.

Tsis muaj zog ntawm Immersion Tin

1. Kev khaws cia siab, yuav ua rau cov ntiv tes hloov xim.

2. Tin whiskers tuaj yeem ua rau luv luv thiab cov teeb meem sib koom ua ke, yog li ua rau lub sijhawm luv luv.

3. Tsis yooj yim rau kev kuaj hluav taws xob.

4. Cov txheej txheem muaj cov carcinogens.

Pom zoo

ENIG (Electroless Nickel Immersion Gold) yog siv dav siv txheej txheej txheej txheej txheej txheej txheej txheej txheej ntawm 2 hlau txheej, qhov uas npib tsib xee ncaj qha tso rau ntawm tooj liab thiab tom qab ntawd kub atoms raug plated rau tooj liab los ntawm kev hloov pauv. Lub thickness ntawm npib tsib xee puab txheej yog feem ntau 3-6um, thiab cov deposition thickness ntawm kub txheej txheej yog feem ntau 0.05-0.1um. Cov npib tsib xee ua ib txheej txheej ntawm cov solder thiab tooj liab. Kev ua haujlwm ntawm kub yog los tiv thaiv npib tsib xee oxidation thaum lub sij hawm cia, yog li ncua lub txee lub neej, tab sis cov txheej txheem immersion kub kuj tuaj yeem tsim cov nplaim zoo.

Kev khiav dej num ntawm ENIG yog: tu--> etching--> catalyst--> tshuaj nickel plating--> kub deposition--> ntxuav residue.

Qhov zoo ntawm ENIG

1. Haum rau cov hlau lead dawb (RoHS raws) cov khoom siv.

2. Zoo heev nto smoothness.

3. Lub neej txee ntev thiab ruaj khov nto.

4. Haum rau Al hlau sib txuas.

Tsis muaj zog ntawm ENIG

1. Nqi vim siv kub.

2. Cov txheej txheem nyuaj, nyuaj los tswj.

3. Yooj yim los tsim qhov tshwm sim ntawm lub ncoo dub.

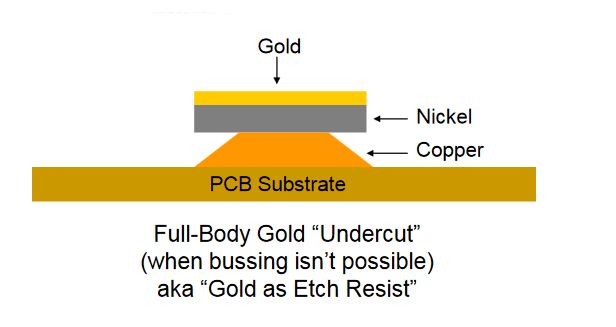

Electrolytic Nickel / Kub (nyuaj kub / mos kub)

Electrolytic npib tsib xee kub tau muab faib ua "nyuaj kub" thiab "mos kub". Cov kub kub muaj qhov purity tsawg thiab feem ntau yog siv hauv cov ntiv tes kub (PCB ntug connectors), PCB tiv tauj lossis lwm qhov chaw hnav-tiv taus. Lub thickness ntawm kub yuav txawv raws li qhov yuav tsum tau ua. Cov kub mos muaj ntau dua purity thiab feem ntau yog siv nyob rau hauv kev sib txuas ntawm hlau.

Qhov zoo ntawm Electrolytic Nickel / Kub

1. Lub neej txee ntev dua.

2. Haum rau kev sib cuag hloov thiab xaim kev sib txuas.

3. Hard kub yog haum rau kev kuaj hluav taws xob.

4. Lead dawb (RoHS raws)

Tsis muaj zog ntawm Electrolytic Nickel / Kub

1. Feem ntau kim nto tiav.

2. Electroplating kub ntiv tes xav tau cov xov hlau txuas ntxiv.

3. Muaj kub muaj tsis zoo solderability. Vim lub thickness ntawm kub, thicker txheej yog nyuaj rau solder.

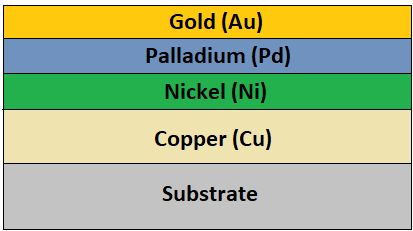

PRINCIPAL

Electroless Nickel Electroless Palladium Immersion Kub los yog ENEPIG tau nce siv rau PCB nto tiav. Piv nrog rau ENIG, ENEPIG ntxiv ib txheej ntxiv ntawm palladium ntawm npib tsib xee thiab kub los tiv thaiv cov nickel txheej los ntawm corrosion thiab tiv thaiv kev tsim cov ntaub qhwv dub uas yooj yim tsim nyob rau hauv ENIG nto tiav txheej txheem. Lub deposition thickness ntawm npib tsib xee yog hais txog 3-6um, lub thickness ntawm palladium yog hais txog 0.1-0.5um thiab lub thickness ntawm kub yog 0.02-0.1um. Txawm hais tias lub thickness ntawm kub yog me dua ENIG, ENEPIG yog kim dua. Txawm li cas los xij, qhov tsis ntev los no poob ntawm cov nqi palladium tau ua rau ENEPIG tus nqi pheej yig dua.

Qhov zoo ntawm ENEPIG

1. Muaj tag nrho cov txiaj ntsig ntawm ENIG, tsis muaj qhov tshwm sim ntawm lub ncoo dub.

2. Tsim nyog rau kev sib txuas ntawm cov hlau ntau dua li ENIG.

3. Tsis muaj kev pheej hmoo ntawm corrosion.

4. Lub sijhawm cia ntev, tsis muaj txhuas (RoHS raws)

Tsis muaj zog ntawm ENEPIG

1. Cov txheej txheem nyuaj, nyuaj rau tswj.

2. Tus nqi siab.

3. Nws yog ib txoj kev tshiab thiab tseem tsis tau paub tab.