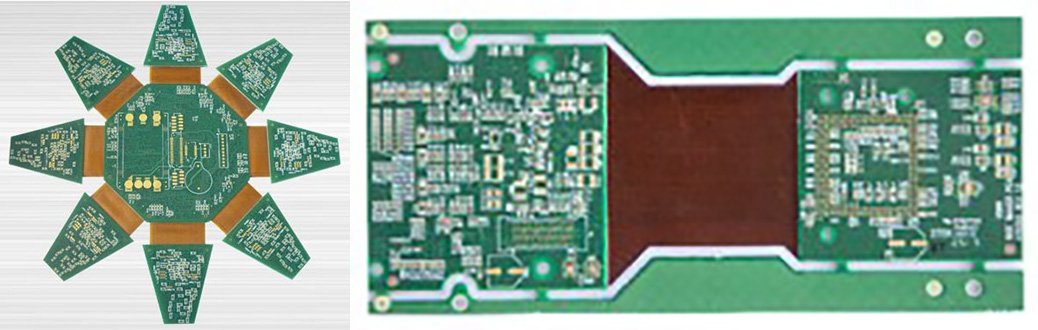

Rigid-Flex Board

Ntau Efficient Advanced Technology & Perfect Solution.

Qhov zoo ntawm Rigid-Flex Board

Niaj hnub no, tus tsim yog nce mus nrhiav miniaturization, tsis tshua muaj nqi thiab siab ceev ntawm cov khoom, tshwj xeeb tshaj yog nyob rau hauv lub mobile ntaus ntawv ua lag luam, uas feem ntau yuav muaj high-density hluav taws xob circuits. Siv Rigid-Flex Boards yuav yog qhov kev xaiv zoo tshaj plaws rau cov khoom siv peripheral txuas nrog IO. Xya qhov zoo tshaj plaws los ntawm kev tsim cov kev xav tau ntawm kev sib koom ua ke ntawm cov ntaub ntawv yooj yim board thiab cov ntaub ntawv nruj hauv cov txheej txheem tsim khoom, sib txuas cov 2 substrate cov ntaub ntawv nrog prepreg, thiab tom qab ntawd ua tiav interlayer hluav taws xob kev sib txuas ntawm conductors los ntawm-qhov lossis qhov muag tsis pom / faus vias yog raws li hauv qab no :

3D sib dhos los txo cov circuits

Kev sib txuas zoo dua kev ntseeg

Txo tus naj npawb ntawm cov khoom thiab qhov chaw

Zoo dua impedance sib xws

Muaj peev xwm tsim cov txheej txheem stacking heev

Ua raws li kev tsim qauv zoo nkauj dua

Txo qhov loj me

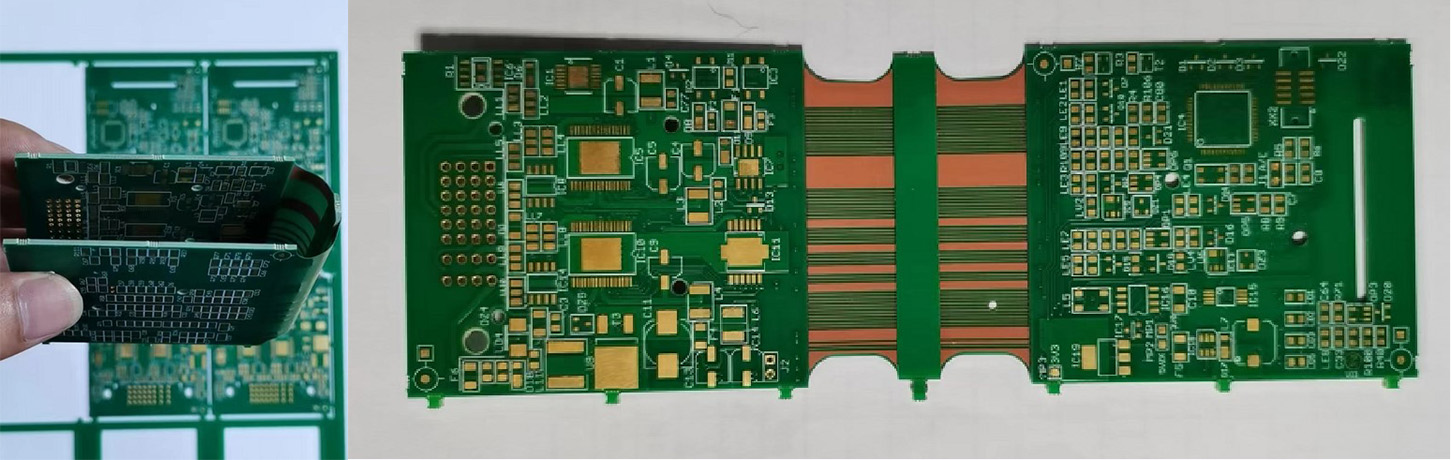

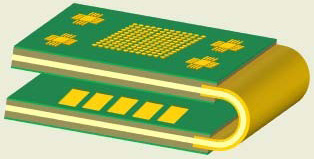

Lub rigid-flex yog ib lub rooj tsavxwm uas sib txuas ua ke rigidity thiab saj zawg zog, ua ob qho tib si rigidity ntawm rigid board thiab yooj ntawm lub rooj tsavxwm hloov tau.

Semi FPC

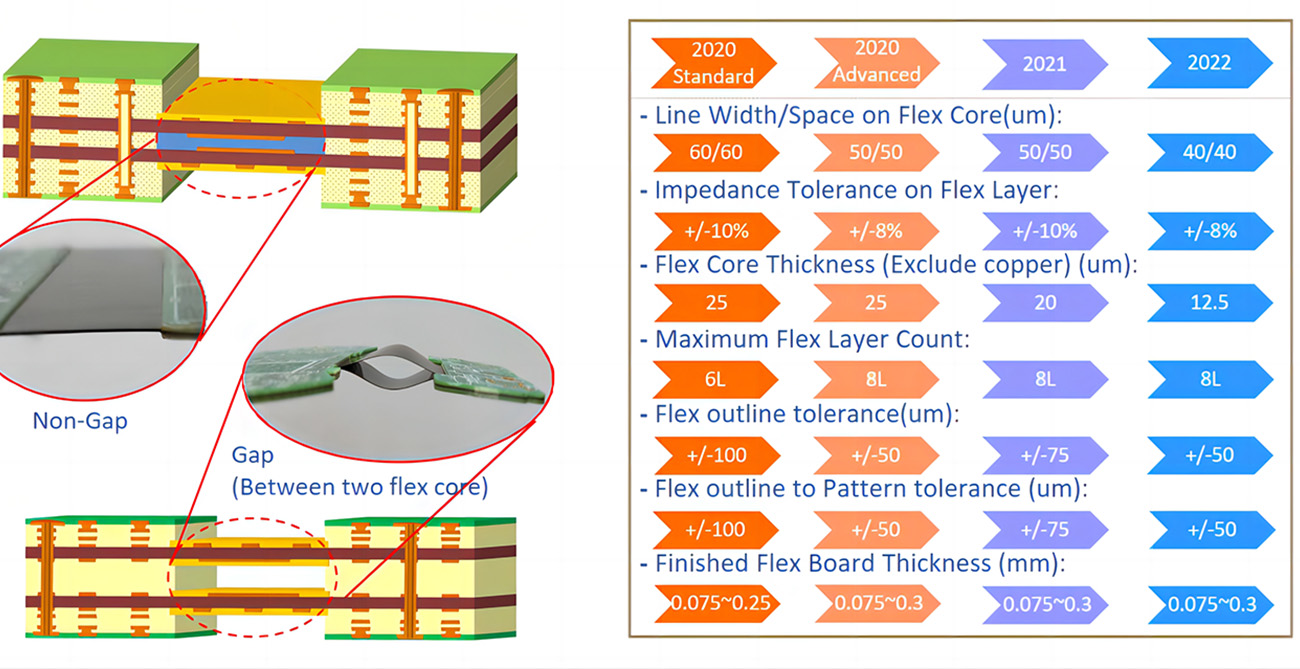

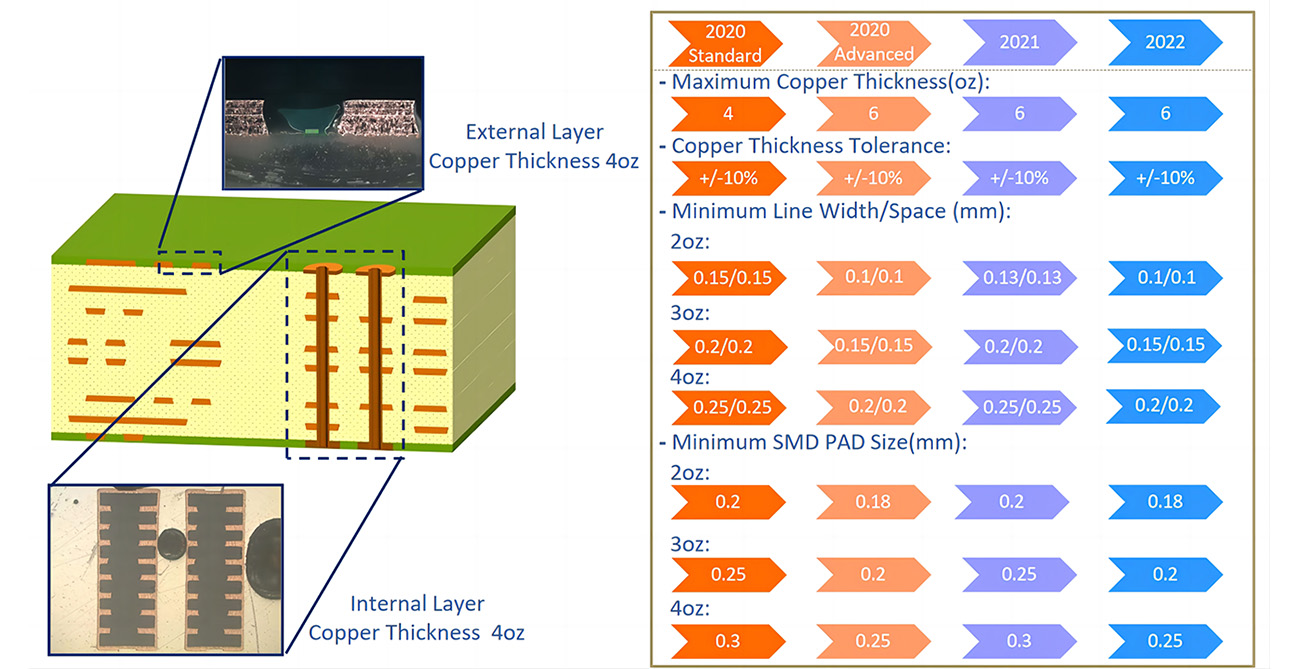

Muaj peev xwm Roadmap

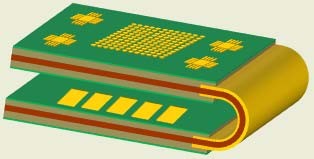

| Yam khoom | Flex - nruj | Regal | Semi-Flex |

| Daim duab |  |  |  |

| Cov khoom siv yooj yim | Polyimide | FR4 + Coverlay (Polyimide) | FR4 |

| Flexible thickness | 0.025 ~ 0.1mm (Tsis suav nrog tooj liab) | 0.05 ~ 0.1mm (Tsis suav nrog tooj liab) | Tseem Thickness: 0.25 +/- 0.05mm (Dedicated Khoom: EM825 (I)) |

| Khoov lub kaum sab xis | Max 180 ° | Max 180 ° | Max 180 ° (Flex txheej 2) |

| Flexural Endurance; IPC-TM-650, Txoj Kev 2.4.3. | Tias | ||

| Bending Test; 1) Txoj kab uas hla: 6.25mm | |||

| Daim ntawv thov | Flex rau nruab & Dynamic (ib sab) | Flex rau nruab | Flex rau nruab |

| Nto tiav | Tus nqi | Tus neeg muab khoom | |

| Volunteer Fire Department |  | 0.2 ~ 0.6um; 0.2 ~ 0.35um | Enthone Shikoku tshuaj |

| Pom zoo |  | Au: 0.03 ~ 0.12um, Ni: 2.5 ~ 5um | ATO tech/Chuang Zhi |

| Selective ENIG |  | Au: 0.03 ~ 0.12um, Ni: 2.5 ~ 5um | ATO tech/Chuang Zhi |

| PRINCIPAL |  | Au: 0.05 ~ 0.125um, Pd: 0.05 ~ 0.125um, Ni : 5 ~ 10um | Chuang Zhi |

| Hard kub |  | Au: 0.2 ~ 1.5um, Ni: min 2.5um | Tus neeg them nyiaj |

| Mos Kub |  | Au: 0.15 ~ 0.5um, Ni: min 2.5um | EJA |

| Immersion Tin |  | Min: 1 um | Enthone / ATO Tech |

| Immersion Nyiaj |  | 0.15 ~ 0.45 hli | Macdermid |

| HASL & Lead free HASL (OS) |  | 1 ~ 25 hli | Nihon Superior |

Au/Ni Type

● Kub plating yuav muab faib ua nyias kub thiab tuab kub raws li thickness. Feem ntau, kub hauv qab 4u "(0.41um) yog hu ua nyias kub, thaum kub saum 4u" yog hu ua kub kub. ENIG tsuas tuaj yeem ua kub nyias, tsis kub kub. Tsuas yog kub plating yuav ua tau ob qho tib si nyias thiab tuab kub. Qhov siab tshaj plaws ntawm tuab kub ntawm lub rooj tsavxwm hloov tau tuaj yeem dhau 40u ". Cov kub kub yog siv nyob rau hauv kev ua hauj lwm ib puag ncig nrog kev sib txuas los yog hnav tsis kam yuav tsum tau ua.

● Kub plating tuaj yeem muab faib ua kub kub thiab tawv kub los ntawm hom. Cov kub kub yog kub zoo tib yam, thaum kub kub yog cobalt muaj kub. Nws yog qhov tseeb vim hais tias cobalt tau ntxiv tias qhov hardness ntawm cov txheej kub nce siab tshaj 150HV kom ua tau raws li qhov yuav tsum tau ua.

| Hom khoom | Cov khoom | Tus neeg muab khoom | |

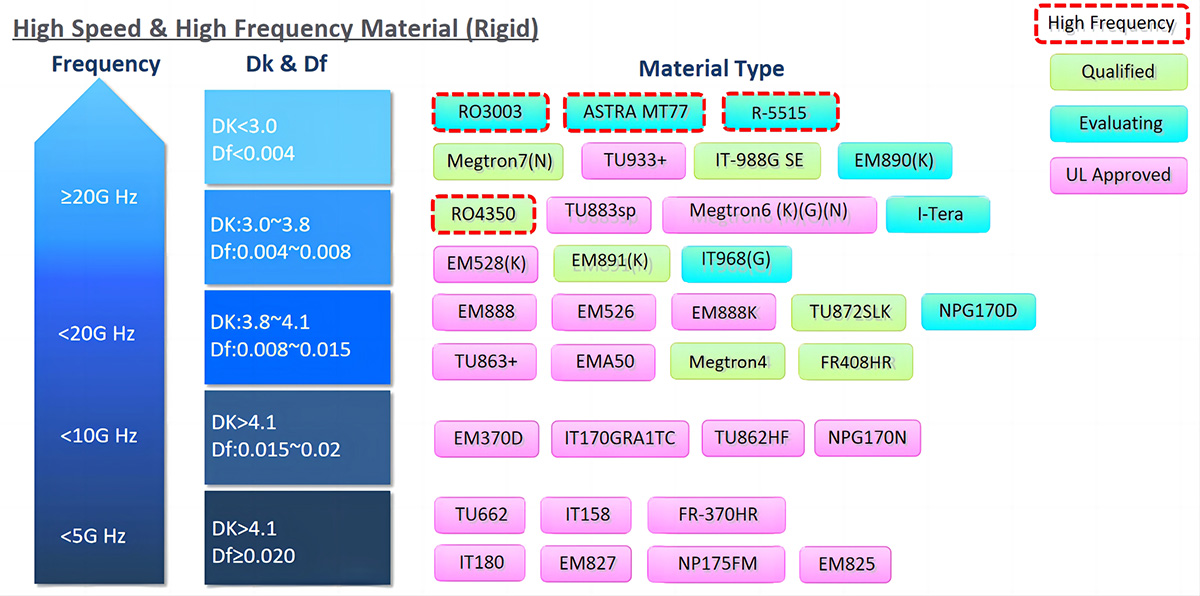

| Rigid Khoom | Poob li qub | DK> 4.2, DF> 0.02 | NanYa / EMC / TUC / ITEQ / ShengYi / Isola / Doosan thiab lwm yam. |

| Nruab nrab poob | DK> 4.1, DF: 0.015 ~ 0.02 | NanYa / EMC / TUC / ITEQ thiab lwm yam. | |

| Kev poob qis | DK: 3.8 ~ 4.1, DF: 0.008 ~ 0.015 | EMC / NanYa / TUC / Isola / Panasonic thiab lwm yam. | |

| Loss tsawg heev | DK: 3.0 ~ 3.8, DF: 0.004 ~ 0.008 | EMC / Panasonic / Rogers / TUC / Isola / ITEQ / NanYa thiab lwm yam. | |

| Ultra Tsawg Loss | DK | Rogers / TUC / ITEQ / Panasonic / Isola thiab lwm yam. | |

| BT | Xim: Dawb / Dub | MGC / Hitachi / NanYa / ShengYi thiab lwm yam. | |

| Copper Foil | Txuj | Roughness (RZ) = 6.34um | NanYa, KB, LCY |

| RTF | Roughness (RZ) = 3.08um | NanYa, KB, LCY | |

| VLP | Roughness (RZ) = 2.11um | MITSUI, Circuit Foil | |

| HVLP | Roughness (RZ) = 1.74um | MITSUI, Circuit Foil | |

| Hom khoom | Normal DK/DF | Tsawg DK/DF | |||

| Cov khoom | Tus neeg muab khoom | Cov khoom | Tus neeg muab khoom | ||

| Flex Khoom | FCCL (Nrog ED & RA) | Ib txwm Polyimide DK: 3.0 ~ 3.3 DF: 0.006 ~ 0.009 | Thinflex / Panasonic / Taiflex | Hloov kho Polyimide DK: 2.8 ~ 3.0 DF: 0.003 ~ 0.007 | Thinflex / Taiflex |

| Coverlay (Dub / Daj) | Ib txwm Adhesive DK: 3.3 ~ 3.6 Df: 0.01 ~ 0.018 | Taiflex / Dupont | Hloov Adhesive DK: 2.8 ~ 3.0 DF: 0.003 ~ 0.006 | Taiflex / Arisawa | |

| Bond-film (Thickness: 15/25/40 um) | Ib txwm Epoxy DK: 3.6 ~ 4.0 DF: 0.06 | Taiflex / Dupont | Hloov kho Epoxy DK: 2.4 ~ 2.8 DF: 0.003 ~ 0.005 | Taiflex / Arisawa | |

| S/M Ink | Solder mask; Xim: Ntsuab / Xiav / Dub / Dawb / Daj / Liab | Ib txwm Epoxy DK: 4.1 DF: 0.031 | Taiyo / OTC / AMC | Hloov kho Epoxy DK: 3.2 DF: 0.014 | Taiyo |

| Dab neeg tus cwj mem | Xim Xim: Dub / Dawb / Yellow Inkjet Xim: Dawb | AMC | |||

| Lwm yam khoom siv | IMS | Insulated Metallic Substrates (nrog Al lossis Cu) | EMC / Ventec | ||

| Siab Thermal conductive | 1.0 / 1.6 / 2.2 (W / M * K) | ShengYi / Ventec | |||

| Kuv | Cov ntawv nyiaj (SF-PC6000-U1 / SF-PC8600-C) | Taus | |||

High Speed & High Frequency Material (Slexible)

| DK | Df | Hom khoom | |

| FCCL (Polyimide) | 3.0 ~ 3.3 | 0.006-0.009 Nws | Panasonic R-775 series; Thinflex A series; Thinflex W series; Taiflex 2up series |

| FCCL (Polyimide) | 2.8-3.0 Nws | 0.003-0.007 Nws | Thinflex LK series; Taiflex 2FPK series |

| FCCL (LCP) | 2.8-3.0 Nws | 0.002 ib | Thinflex LC series; Panasonic R-705T se; Taiflex 2CPK series |

| Coverlay | 3.3-3.6 | 0.01-0.018 Nws | Dupont FR series; Taiflex FGA series; Taiflex FHB series; Taiflex FHK series |

| Coverlay | 2.8-3.0 Nws | 0.003-0.006 Nws | Arisawa C23 series; Taiflex FXU series |

| Daim ntawv cog lus | 3.6 ~ 4.0 | 0.06 ib | Taiflex BT series; Dupont FR series |

| Daim ntawv cog lus | 2.4-2.8 Nws | 0.003 ~ 0.005 hli | Arisawa A23F series; Taiflex BHF series |

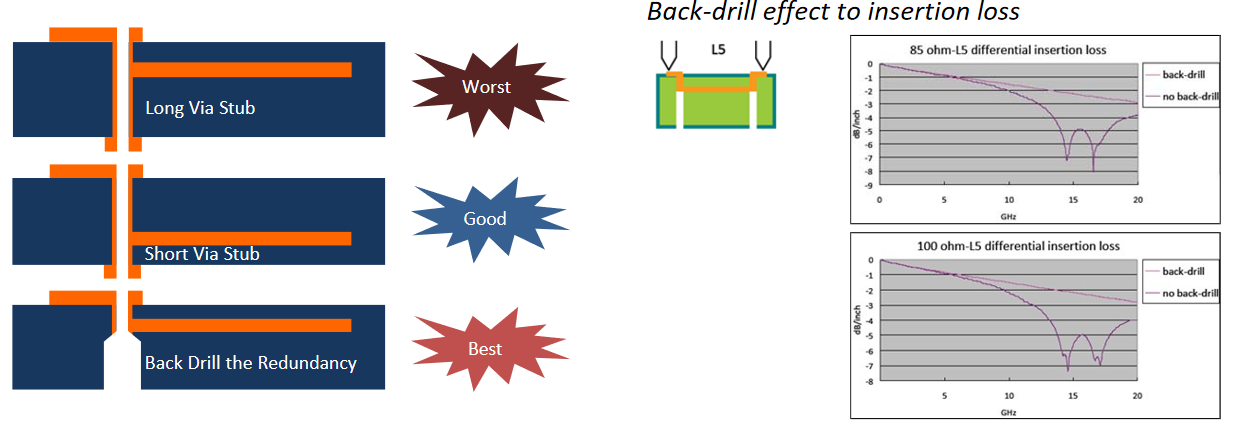

Back Drill Technology

● Cov kab mob Microstrip yuav tsum tsis muaj vias, lawv yuav tsum tau soj ntsuam los ntawm kab mob sab.

● Cov kab nyob rau sab thib ob yuav tsum tau soj ntsuam los ntawm sab thib ob (Lub community launch yuav tsum nyob rau sab ntawd).

● Cov qauv tsim zoo yog tias cov kab stripline yuav tsum tau soj ntsuam los ntawm qhov twg sab feem ntau txo qhov ntawm cov stub.

● Cov txiaj ntsig zoo tshaj plaws rau stripline yuav tau txais los ntawm kev siv luv luv vias uas yog rov qab.

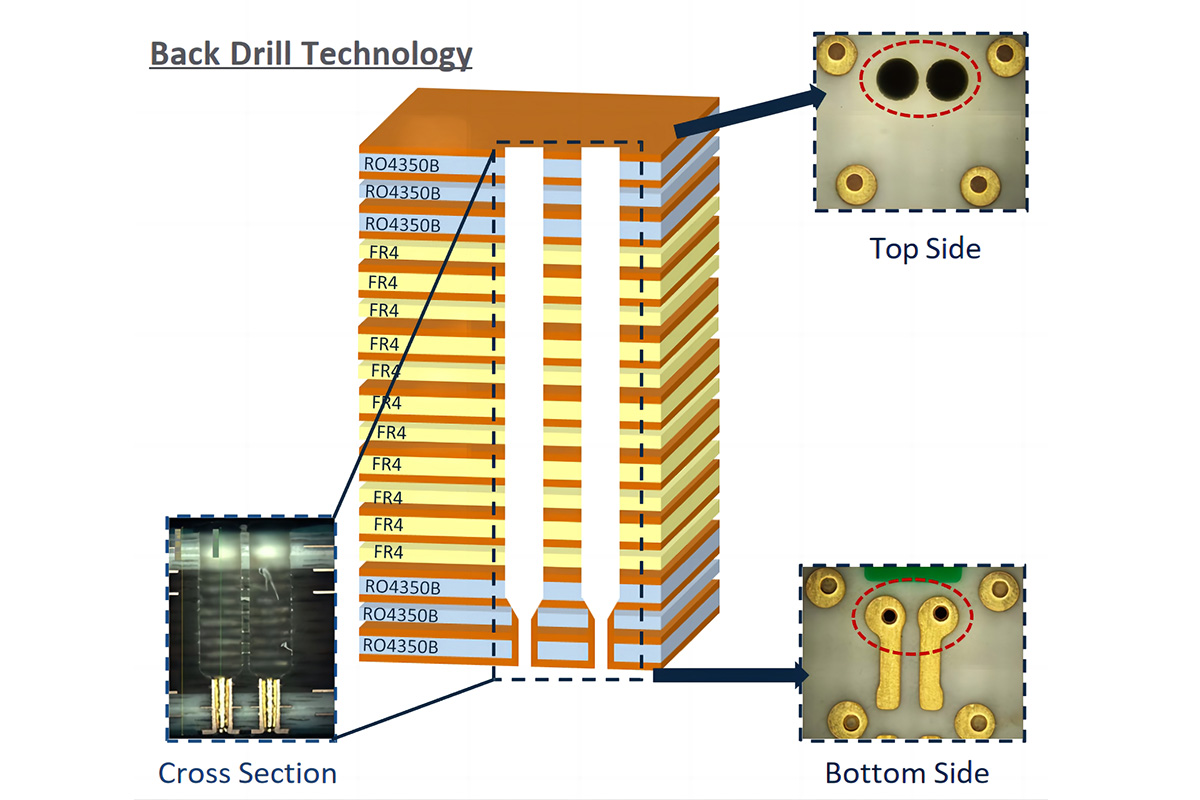

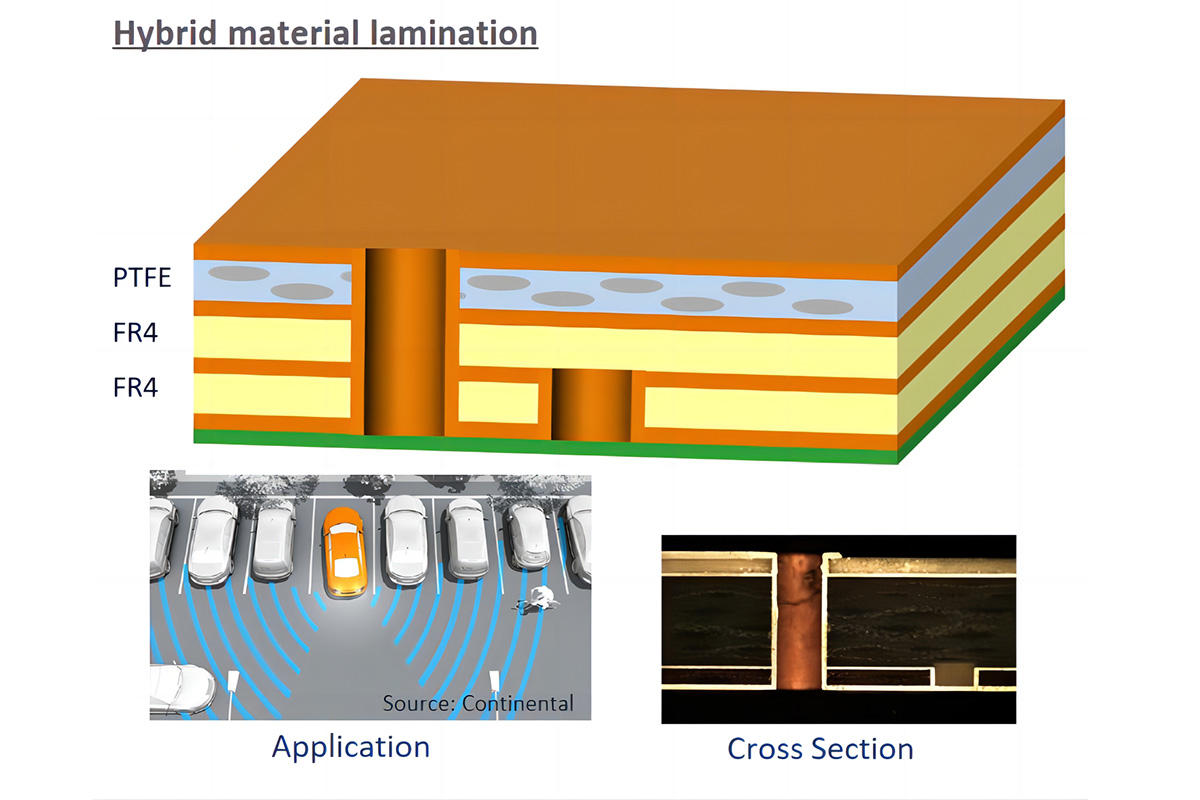

Khoom siv:Automotive radar sensor

Khoom Paub meej:

4 Txheej PCB nrog hybrid khoom (Hydrocarbon + Standard FR4)

Pob: 4L HDI / Asymmetric

Kev sib tw:

Cov khoom siv ntau zaus nrog Standard FR4 Lamination

Tswj qhov tob tob

Khoom siv:Automotive radar sensor

Khoom Paub meej:

4 Txheej PCB nrog hybrid khoom (Hydrocarbon + Standard FR4)

Pob: 4L HDI / Asymmetric

Kev sib tw:

Cov khoom siv ntau zaus nrog Standard FR4 Lamination

Tswj qhov tob tob

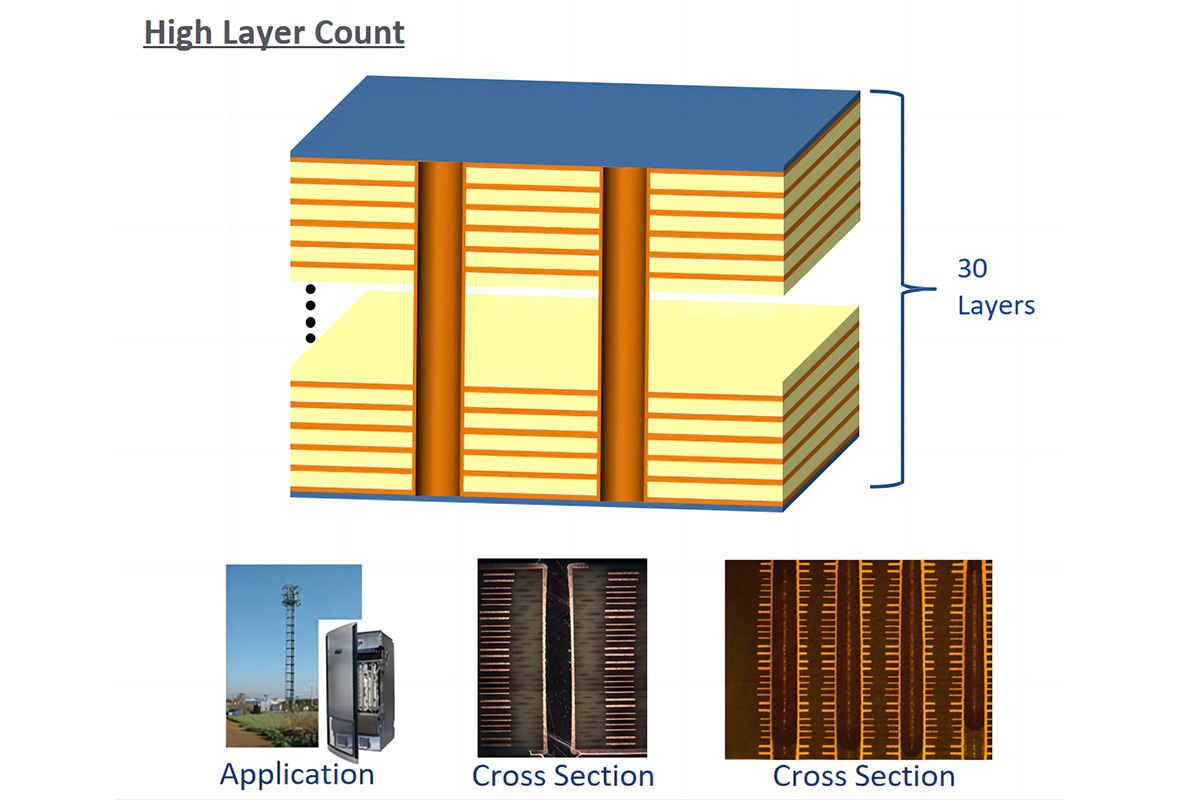

Khoom siv:

Base chaw nres tsheb

Khoom Paub meej:

30 Txheej (homogeneous khoom)

Stack up: High txheej suav / Symmetrical

Kev sib tw:

Kev sau npe rau txhua txheej

High nam piv ntawm PTH

Critical lamination parameter

Khoom siv:

Nco

Khoom Paub meej:

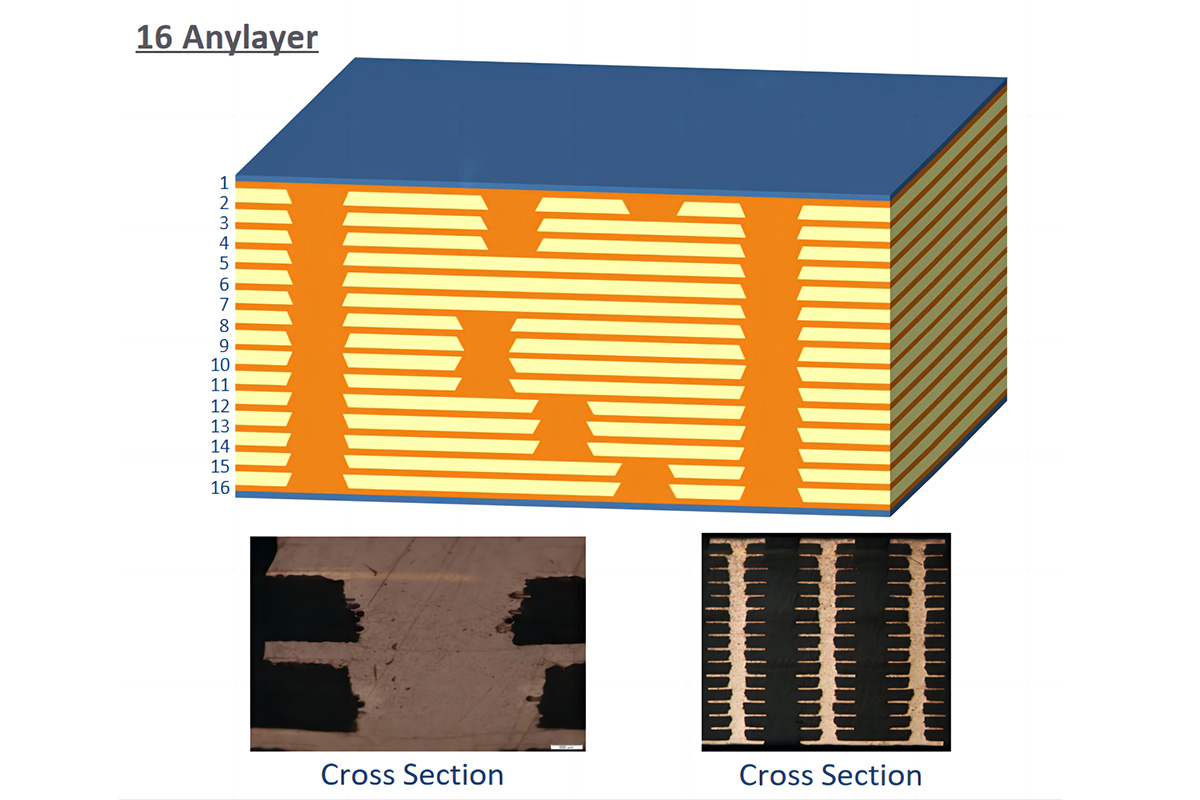

Stack up: 16 Layers Anylayer

IST Kev Xeem: Qhov Ntsuas: 25-190 ℃ Sijhawm: 3 min, 190-25 ℃ Sijhawm: 2min, 1500 Cycles. Resistance hloov tus nqi≤10%, xeem txoj kev: IPC-TM650-2.6.26. Qhov tshwm sim: Pass.

Kev sib tw:

Laminating ntau tshaj 6 zaug

Laser vias qhov tseeb

Khoom siv:

Nco

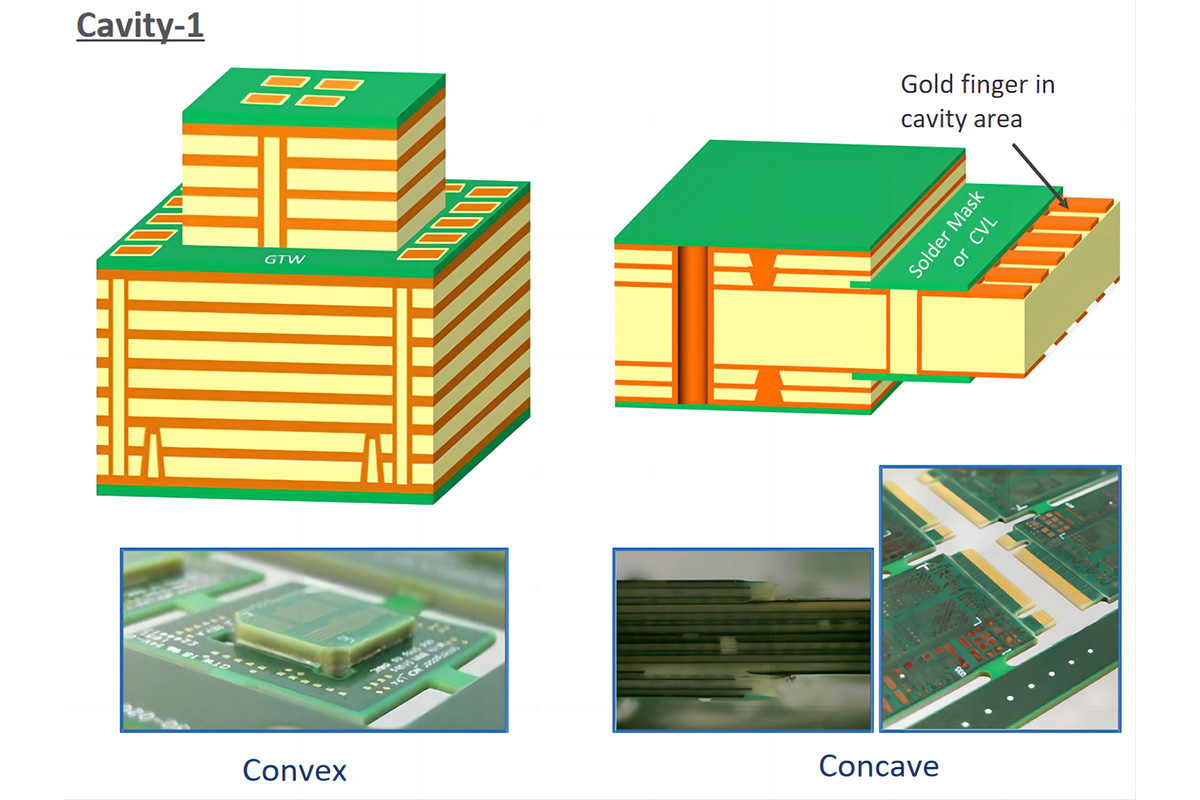

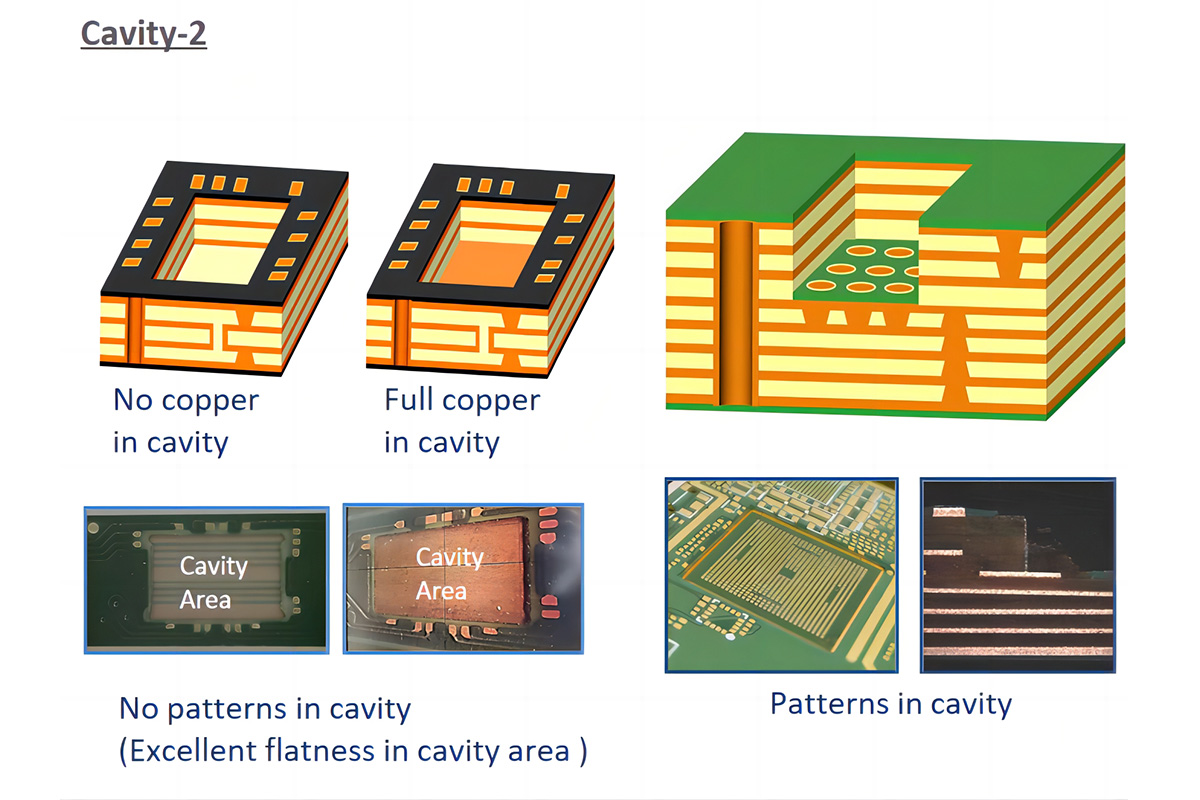

Khoom Paub meej:

Kev sib tw: Cavity

Khoom siv: Standard FR4

Kev sib tw:

Siv De-cap thev naus laus zis ntawm Rigid PCB

Kev sau npe ntawm cov txheej txheem

Tsawg nyem tawm ntawm thaj tsam kauj ruam

Cov txheej txheem tseem ceeb beveling rau G / F

Khoom siv:

Lub koob yees duab Module / Notebook

Khoom Paub meej:

Kev sib tw: Cavity

Khoom siv: Standard FR4

Kev sib tw:

Siv De-cap thev naus laus zis ntawm Rigid PCB

Qhov kev pab cuam laser tseem ceeb thiab tsis muaj nyob hauv De-cap txheej txheem

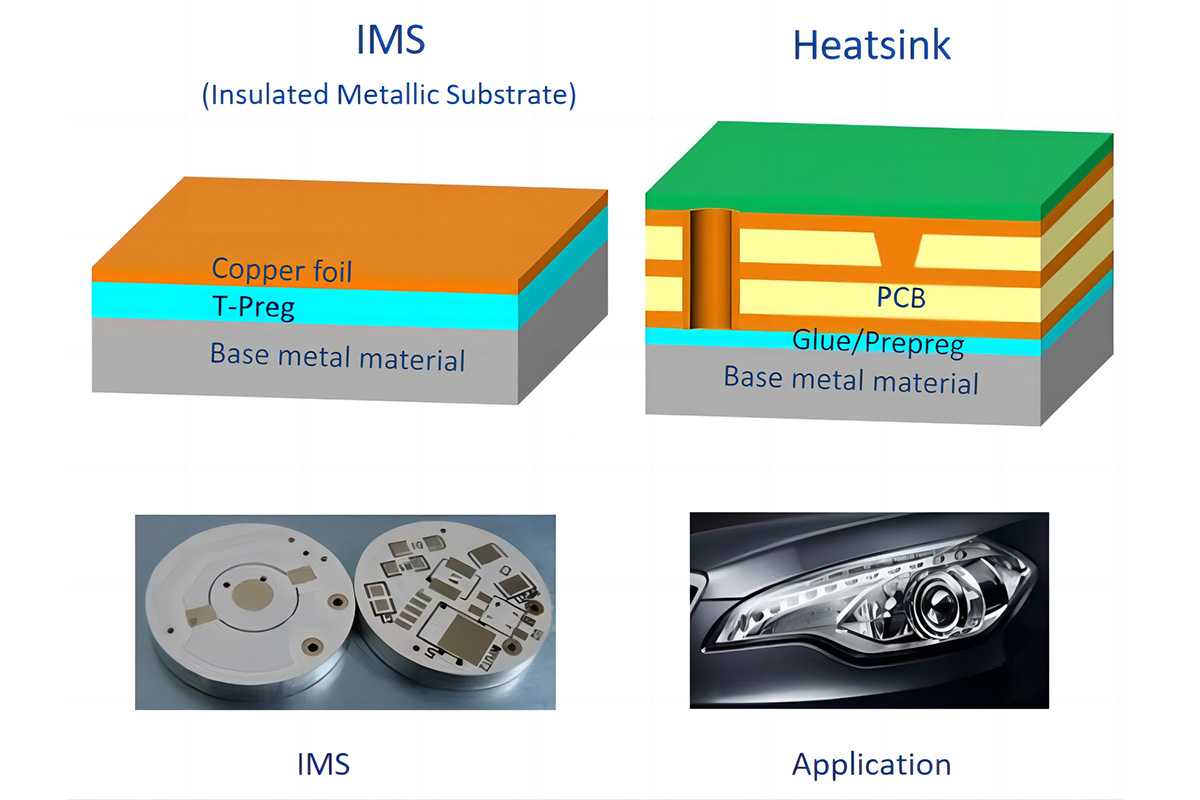

Khoom siv:

Automotive teeb

Khoom Paub meej:

Pob: IMS / Heatsink

Khoom siv: Hlau + Glue / Prepreg + PCB

Kev sib tw:

Aluminium puag thiab tooj liab puag (ib txheej)

Thermal conductivity

FR4 + Glue / Prepreg + Al lamination

Qhov zoo:

Thaum tshav kub kub Dissipation

Khoom Paub meej:

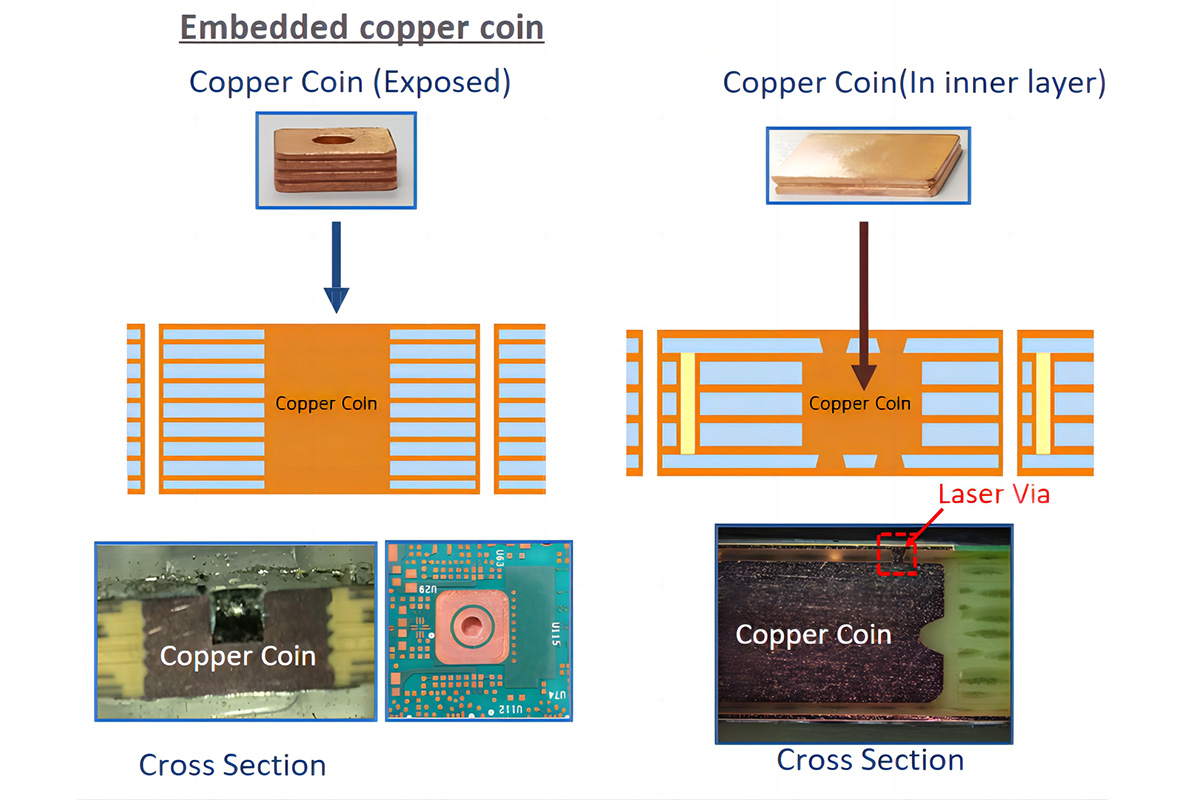

Cov khoom siv ceev ceev (homogeneous)

Pem hauv ntej: Embedded tooj liab npib / Symmetric

Kev sib tw:

Qhov tseeb ntawm npib dimension

Qhov tseeb ntawm lamination qhib

Tseem ceeb resin flow

Khoom siv:

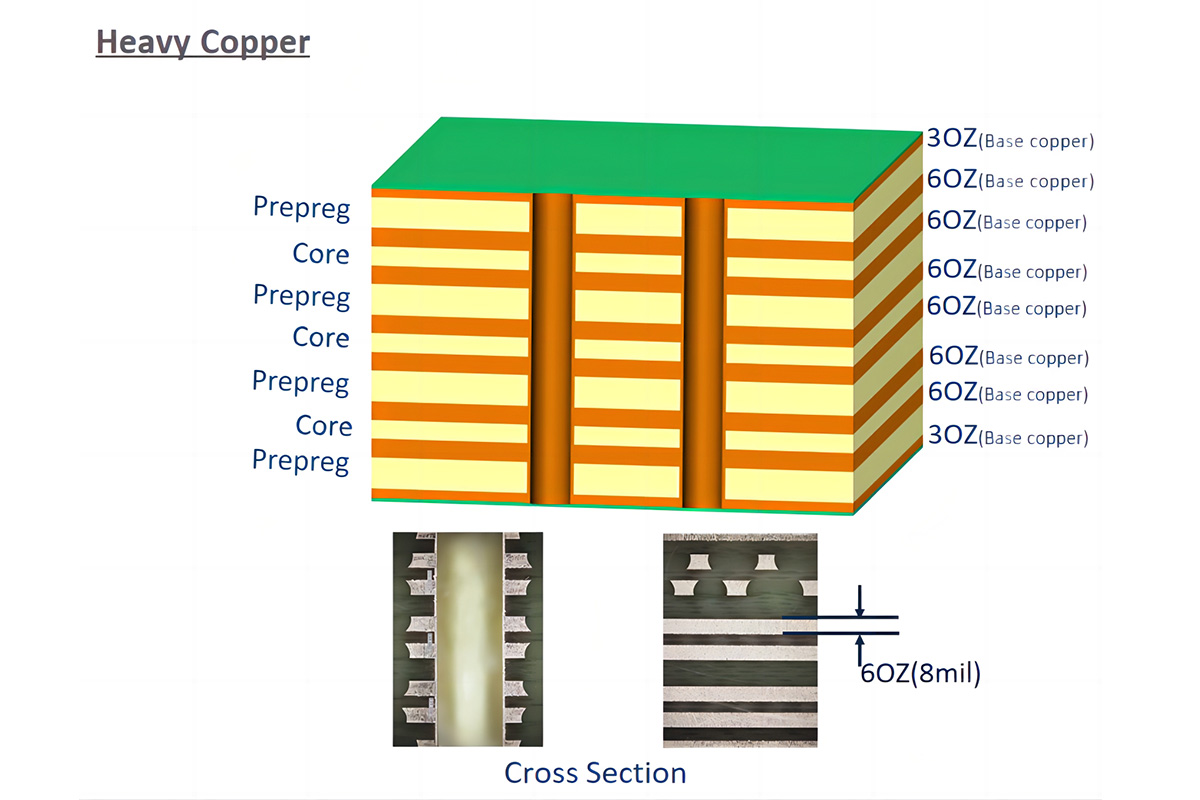

Automotive / Industrial / Base chaw nres tsheb

Khoom Paub meej:

Sab hauv txheej puag tooj liab 6OZ

Sab nrauv txheej puag tooj liab 3OZ / 6OZ Stack up:

6OZ tooj liab hnyav hauv txheej sab hauv

Kev sib tw:

6OZ tooj liab kis tau puv nrog epoxy

Tsis muaj drift hauv lamination ua

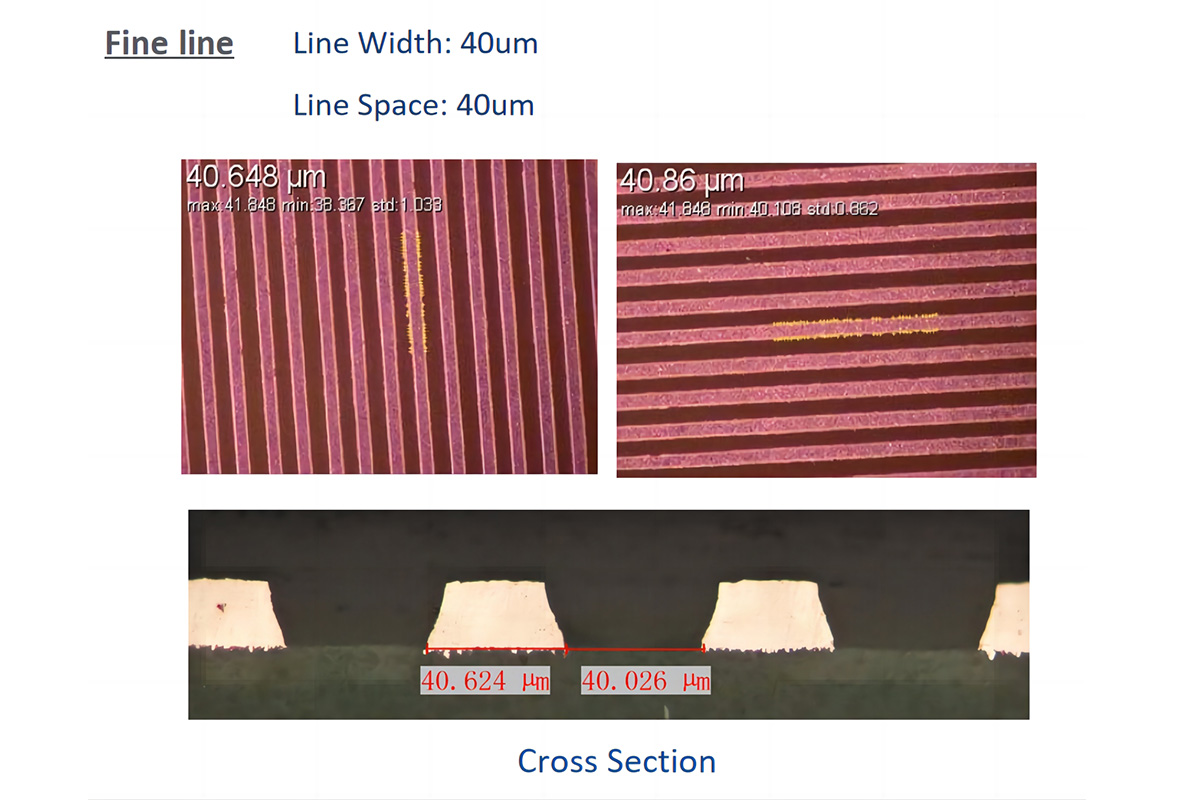

Khoom siv:

Smartphone / SD Card / SSD

Khoom Paub meej:

Pob: HDI / Anylayer

Khoom siv: Standard FR4

Kev sib tw:

Tsawg profile / RTF Cu ntawv ci

Plating uniformity

High daws teeb meem qhuav zaj duab xis

LDI nthuav tawm (Laser Direct Duab)

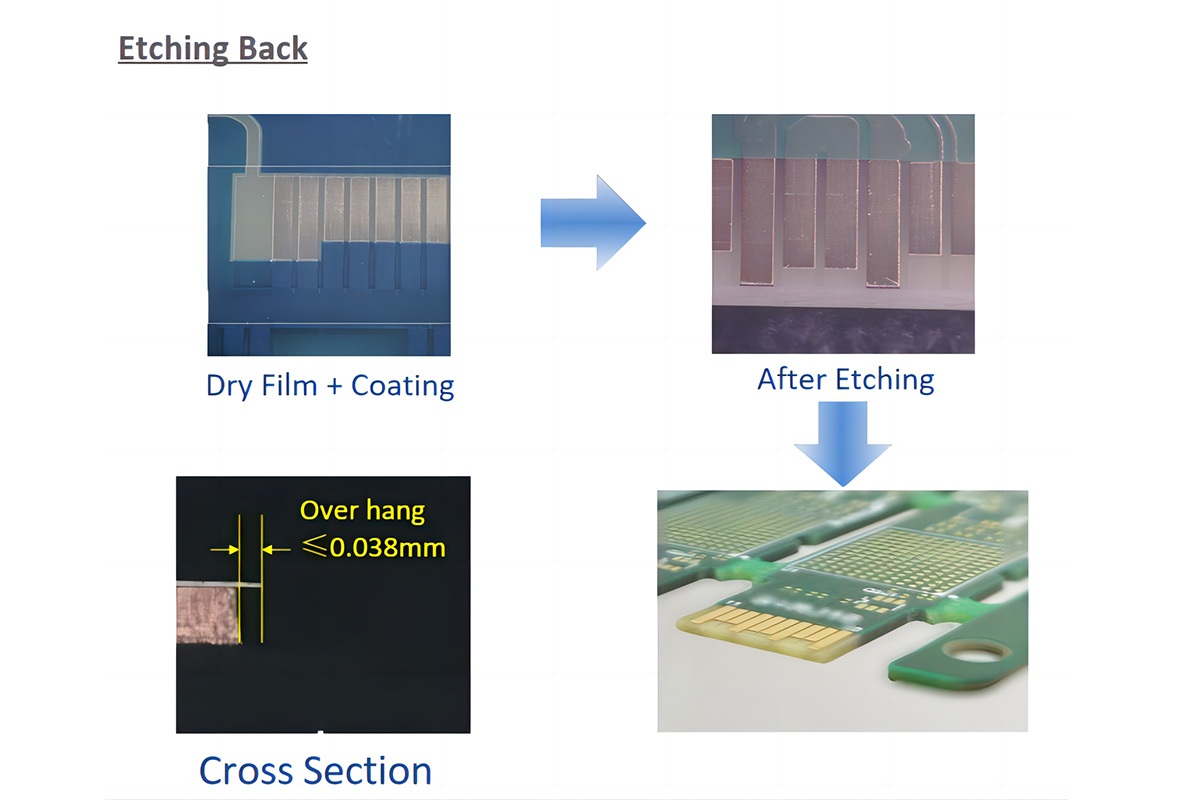

Khoom siv:

Kev sib txuas lus / SD Card / Optical Module

Khoom Paub meej:

Pob: HDI / Anylayer

Khoom siv: Standard FR4

Kev sib tw:

Tsis muaj qhov sib txawv ntawm tus ntiv tes ntug thaum PCB hauv kev ua haujlwm kub plating

Tshwj xeeb resistant zaj duab xis

Khoom siv:

Kev lag luam

Khoom Paub meej:

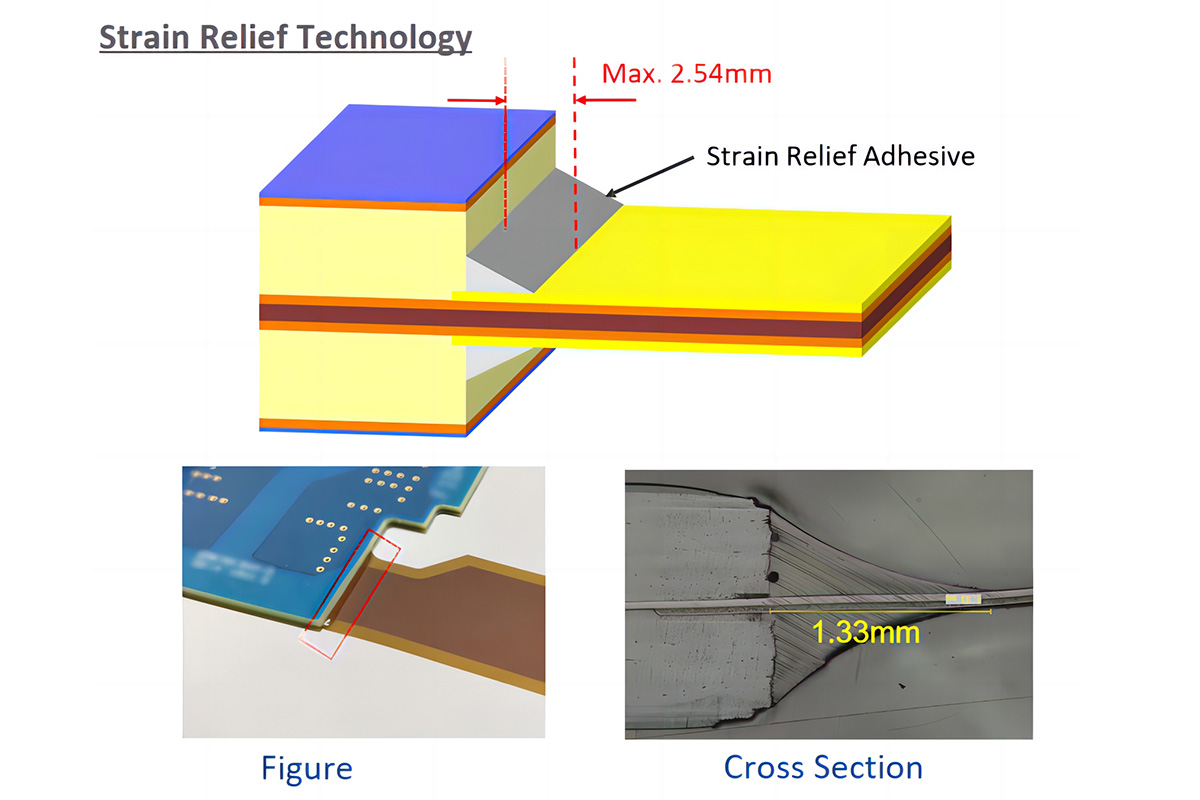

Sib dhos: Rigid-Flex

Nrog Eccobond ntawm Rigid-Flex transformation

Kev sib tw:

Qhov tseem ceeb txav ceev thiab qhov tob rau ncej

Critical cua siab parameter