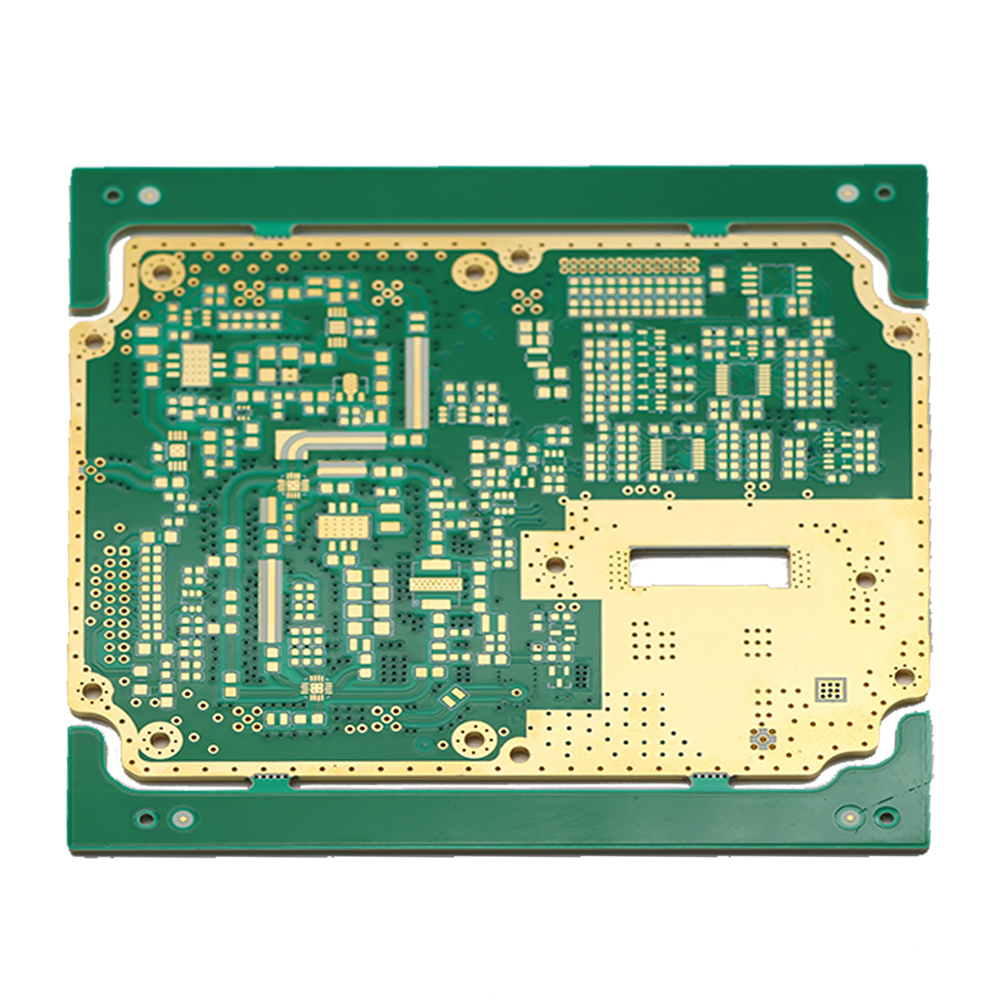

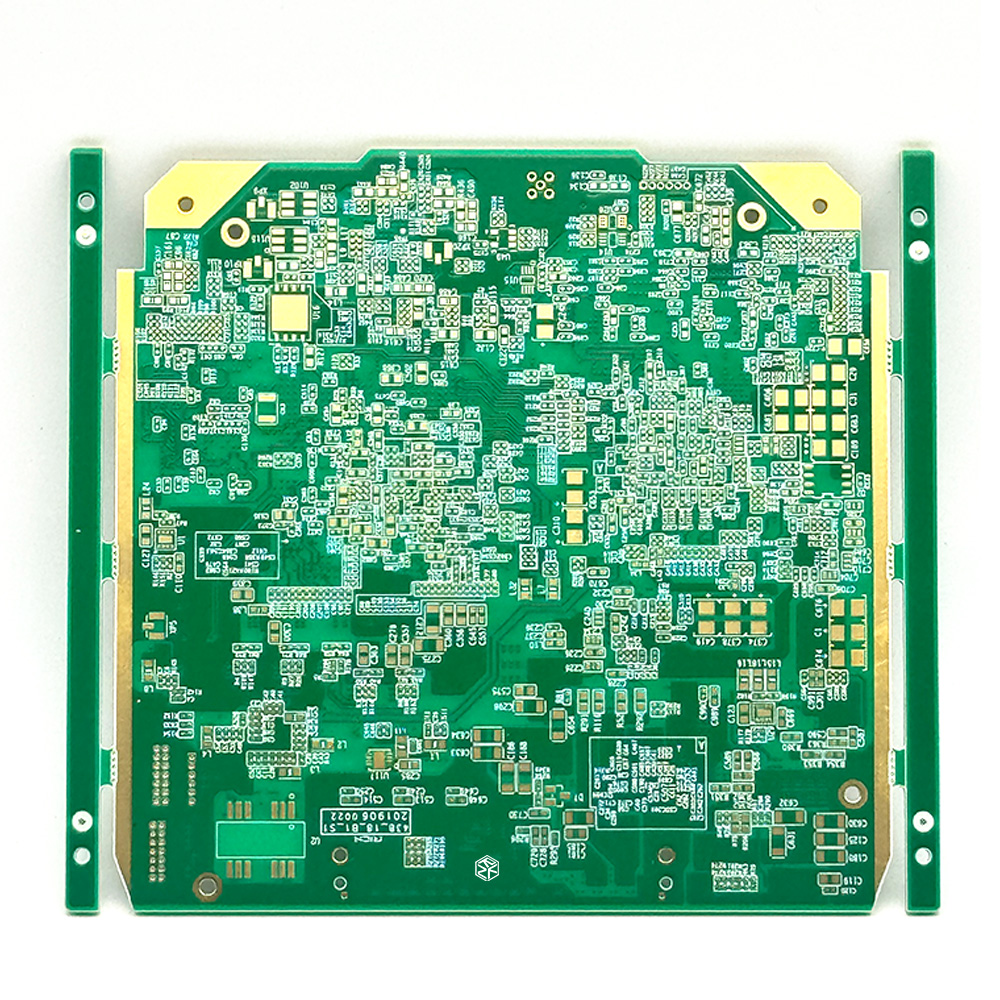

Optical Module HDI PCB Optical Module Gold Finger PCB

Mirayiridzo yekugadzira zvigadzirwa

| Type | maviri akaturikidzana HDI, impedance, resin plug gomba |

| Nyaya | Panasonic M6 Copper-Clad Laminate |

| Number of layer | 10L |

| Board Ukobvu | 1.2mm |

| Single size | 150*120mm/1SET |

| Surface finish | MUKURU |

| Mukati mhangura ukobvu | 18um |

| Kunze kwendarira ukobvu | 18um |

| Ruvara rwe solder mask | girini (GTS, GBS) |

| Silkscreen ruvara | chena(GTO,GBO) |

| Kuburikidza nekurapa | 0.2mm |

| Density ye mechanical drilling gomba | 16W/㎡ |

| Density ye laser drilling gomba | 100W/㎡ |

| Min kuburikidza nehukuru | 0.1mm |

| Min mutsara upamhi / nzvimbo | 3/3mil |

| Aperture ratio | 9mil |

| Kudzvanya nguva | 3 nguva |

| Nguva dzekuchera | 5nguva |

| PN | E240902A |

Key Control Points muKugadzirwa kweOptical Module HDI Gold Finger PCBs

- 1, Precision Etching Control Iyo wiring yeminwe yegoridhe uye HDI PCB yakaoma kwazvo, ichiita kutonga kweiyo etching maitiro akanyanya kukosha. Etching isina kunaka inogona kutungamira kune isina kuenzana mutsara wakafara, mapfupi maseketi, kana akavhurika maseketi. Naizvozvo, yakakwirira-chaiyo etching michina inofanirwa kushandiswa, uye nguva dzose calibration inodiwa kuti ive nechokwadi chekurongeka uye kuenderana mukuita etching.

3, Lamination process Control Lamination inhanho yakakosha uko akawanda PCB akatsikirirwa pamwe chete. Kudzora tembiricha, kudzvanywa, uye nguva panguva yekumisikidza kwakakosha kuve nechokwadi chekubatana kwakasimba kwezvikamu uye yunifomu yebhodhi ukobvu. Kushambidzika kwakashata kunogona kukonzera delamination kana voids, zvichikanganisa kushanda kwemagetsi uye simba remagetsi.

4、Goridhe Finger Plating Thickness Control Ukobvu hwegoridhe plating paminwe yegoridhe inobata zvakananga hupenyu hwekuisa uye kuvimbika kwekubata. Kana iyo yegoridhe yakanyanyisa kuonda, inogona kupera nekukurumidza; kana yakanyanya kukora, inowedzera mari. Naizvozvo, panguva yekuputira, nguva yekuisa goridhe uye huwandu hwazvino hunofanirwa kudzorwa zvakanyanya kuti ive nechokwadi chekuti ukobvu hweplating hunosangana nezviyero (kazhinji 30-50 microinches).

5, Impedance Control uye Testing Optical module HDI PCBs dzinowanzobata masaini ekumhanya, zvichiita kuti impedance kudzora kuve kwakakosha. Munguva yekugadzira, impedance yekuyedza michina inofanirwa kushandiswa kutarisa uye kuyera yakakosha masaini maratidziro munguva-chaiyo, kuve nechokwadi chekuti iyo impedance iri mukati meiyo dhizaini renji (semuenzaniso, zana ohms). Kusateedzera impedance kunogona kukonzera kusaina kutendeseka nyaya, senge kuratidza uye crosstalk.

6.Soldering Hunhu Kudzora Nekuda kwehukuru hukuru hwezvikamu zvinosanganisirwa muOptical module PCBs, iyo solder process inofanirwa kuve yakanyatso kurongeka. Yepamberi reflow soldering uye wave soldering michina inodiwa, uye solder tembiricha profiles dzinofanira kunyatsodzorwa kuti ive nechokwadi chekusimba kwemajoini ekutengesa uye kuvimbika kwekubatanidza magetsi.

7, Kucheneswa Kwepamusoro uye Dziviriro Padanho rega rega rekugadzira, nzvimbo yePCB inofanirwa kuchengetedzwa yakachena kudzivirira guruva, zvigunwe, kana oxidation masara. Izvi zvinosvibisa zvinogona kukonzera mapfupi emagetsi kana kukanganisa kunaka kweplating. Mushure mekugadzirwa, machira ekudzivirira akakodzera anofanirwa kuiswa kudzivirira unyoro uye zvinosvibisa kubva mukati.

8, Hunhu Kuongorora uye Kuongorora Kwakazara kwemhando yekuongorora, kusanganisira yekutarisa yekuona, yemagetsi kuyedzwa, uye kushanda kwekuyedza, kwakakosha. Nzira dzekuongorora dzakajairwa dzinosanganisira Automated Optical Inspection (AOI), kuyedza probe yekubhururuka, uye ongororo yeX-ray kuona kuti PCB yega yega inosangana nemagadzirirwo akatemwa uye mhando dzemhando.

Kukosha Kwekufambisa muOptical Module HDI PCBs

- Dimensions uye Spacing: Hupamhi uye nzvimbo yezvigunwe zvegoridhe zvinoda kunyatsodzorwa kuti ive nechokwadi chekuenderana neanobatanidza. Kazhinji, kufara kweminwe yegoridhe i 0.5mm, nekupanana kwe 0.5mm.

- Edge Chamfering: Chamfering inowanzodiwa kumicheto yePCB uko kune zvigunwe zvegoridhe kufambisa kupinza mutserendende.

Layer Count uye Stacking: HDI PCBs inowanzo sanganisira multilayer dhizaini kuti ipe mamwe magetsi ekubatanidza sarudzo. Iyo layer count uye stacking dhizaini inofanirwa kutariswa kuti ive nechokwadi chese chiratidzo chekuvimbika uye kusimba kwesimba.

Microvias: Kushandisa tekinoroji yemicrovia, senge mapofu uye yakavigwa vias, inogona kunyatso kudzikisa kureba kweiyo interlayer yekubatanidza, nekudaro kuderedza chiratidzo kunonoka uye kurasikirwa. Aya ma microvias anoda kunyatso kudzora chinzvimbo chavo uye hukuru.

Routing Density: Nekuda kweiyo yakakwira routing density yeHDI mabhodhi, kutarisisa kwakanyanya kunofanirwa kubhadharwa kune hupamhi uye nzvimbo yekutevera. Kazhinji, trace wides i3-4 mil, uye spacing zvakare 3-4 mil.

3.Chiratidzo Kuperera

Yakasiyana Pair Routing: Yakakwira-kumhanya chiratidzo chekufambisa chinowanzo shandiswa mumamodule optical chinoda mutsauko wepairi nzira kudzikisa kukanganiswa kwemagetsi uye chiratidzo chekuratidzira. Hurefu uye kupatsanurwa kwezviviri zviviri zvinofanirwa kuenderana, kuve nechokwadi chekutonga kwe impedance mukati mechikamu chinonzwisisika (semuenzaniso, 100 ohms).

Impedance Kudzora: Mukumhanya-kumhanya chiratidzo chekufambisa, yakasimba impedance control yakakosha. Impedance yekufananidza inogona kuwanikwa nekugadzirisa trace hupamhi, spacing, uye layer stacking.

Via Usage: Kushandiswa kwevias kunofanirwa kudzikiswa, sezvavanounza parasitic capacitance uye inductance, inokanganisa chiratidzo chemhando. Kana zvichidikanwa, zvakakodzera kuburikidza nemhando (senge mapofu uye akavigwa vias) uye nzvimbo dzinofanira kusarudzwa.

Decoupling Capacitors: Kuiswa kwakaringana kwe decoupling capacitors kunobatsira kudzikamisa magetsi emagetsi uye kuderedza ruzha rwemagetsi.

Power Plane Dhizaini: Kutora yakasimba simba ndege dhizaini inovimbisa yunifomu yazvino kugovera uye inoderedza kukanganiswa kwemagetsi (EMI).

Thermal Management: Sezvo optical modules ichigadzira kupisa kwakanyanya panguva yekushanda, magadzirirwo ekupisa anofanirwa kutariswa mukugadzira, sekushandisa thermal vias, conductive materials, kana kupisa sinks kuwedzera kupisa kwekupisa.

6.Kusarudzwa kwezvinhu

Substrate Material: Sarudza ma substrates akakodzera kune yakakwira-frequency application, senge polyimide (PI) kana fluoropolymers, kuve nechokwadi chekuvimbika uye kugadzikana kwekufambisa kwemasaini.

Solder Mask: Shandisa yakakwirira-tembiricha, yakaderera-kurasikirwa solder mask zvinhu kuti uve nechokwadi chekuchengetedzwa kwematanho uye kushanda kwemagetsi.

Goridhe chigunwe HDI PCBs anoshandiswa zvakanyanya munzvimbo dzakasiyana siyana nekuda kwehupamhi hwadzo uye hunhu hwepamusoro-hwekuita:

5, Zvishandiso zveMedical: Mumidziyo yekurapa inodiwa zvakanyanya senge CT scanner, michina yeMRI, uye mamwe maturusi ekuongorora, chigunwe chegoridhe HDI PCBs inova nechokwadi chekufambisa data uye kushanda kwakavimbika kwemidziyo.

- 6, Aerospace: Aya maPCB anoshandiswa mukudzora masisitimu emasatelliti, ndege, uye spacecraft, sezvo ivo vachigona kumirisana nehutsinye hwemamiriro ekunze vachichengetedza kuita kwepamusoro.

- 7, Industrial Kudzora: Mumunda weindasitiri otomatiki, PLCs (Programmable Logic Controllers), uye maindasitiri marobhoti, goridhe chigunwe HDI PCBs inopa yakavimbika kutonga uye kutapurirana chiratidzo.

Chigunwe chegoridhe

Yakadzama Nhanganyaya kune Goridhe Fingers

Zvigunwe zvegoridhe zvinoreva nzvimbo dzakaputirwa negoridhe pamucheto webhodhi rakadhindwa redunhu (PCB). Iwo anowanzo shandiswa kugadzira magetsi ekubatanidza neanobatanidza. Zita rokuti "chigunwe chegoridhe" rinobva pakuonekwa kwavo: zvikamu-zvakafanana negoridhe-zvakaputirwa zvikamu zvakafanana neminwe. Zvigunwe zvegoridhe zvinowanzoshandiswa mumaPCB anoiswa, akadai sememory sticks, graphics cards, nemimwe midziyo, kuti ibatane nema slots. Basa rekutanga rezvigunwe zvegoridhe ndere kupa akavimbika emagetsi ekubatanidza kuburikidza neakanyanya conductive goridhe plating layer uku uchivimbisa kusapfeka uye kusagadzikana kwekuora.

Kurongwa kweGoridhe Fingers

Zvigunwe zvegoridhe zvinogona kuverengerwa zvichienderana nebasa ravo, chinzvimbo, uye maitiro ekugadzira:

Electrical Connection Goridhe Zvigunwe: Izvi zvigunwe zvegoridhe zvinonyanya kushandiswa kupa yakagadzikana magetsi ekubatanidza, senge mumemori stick, makadhi emifananidzo, uye mamwe plug-in module. Vanofambisa masaini emagetsi nekupinzwa mumaslots pabhodhi reamai kana zvimwe zvishandiso.

Power Supply Gold Fingers: Aya anoshandiswa kupa simba kana pasi pekubatanidza, kuve nechokwadi chekuti zvishandiso zvinowana yakagadzikana yekuisa magetsi.

2.Kubva pane Position:

Edge Goridhe Fingers: Kazhinji inowanikwa kumucheto kwePCB, iyo inoshandiswa kune slot yekubatanidza uye inowanzowanikwa mundangariro tsvimbo, makadhi emifananidzo, uye mamodule ekutaurirana. Iyi ndiyo inonyanya kuzivikanwa mhando yemunwe wegoridhe.

Non-Edge Goridhe Fingers: Iyi minwe yegoridhe haisi kumucheto kwePCB asi yakamisikidzwa mukati kune chaiyo yekubatanidza kana mabasa, senge ma test point kana yemukati module yekubatanidza.

3.Kubva pane Manufacturing Process:

Kunyudza Goridhe Zvigunwe: Izvi zvinogadzirwa uchishandisa kemikari deposition process yekuisa chidimbu chegoridhe pafoiri yemhangura. Vane nzvimbo yakatsetseka, yakanaka asi goridhe rakatetepa, rinowanzo shandiswa kubatanidza magetsi epasi-frequency.

Electroplated Gold Fingers: Yakagadzirwa uchishandisa electroplating process, izvi zvigunwe zvegoridhe zvine mukobvu wegoridhe uye zvinoramba kupfeka, zvakakodzerwa nepamusoro-akavimbika kubatanidza magetsi kunoda kuiswa uye kubviswa nguva nenguva, senge mumemory stick uye makadhi emifananidzo. Iyi nzira inowanzo shandisa gobvu regoridhe rakakora ye30-50 microinches kuve nechokwadi chekusimba uye yakanaka conductivity.

4.Kubva paConnection Method:

Yakatwasuka Ipinza Goridhe Zvigunwe: Yakanyatsoiswa mukati meiyo slot, elasticity yeslot inobata zvigunwe zvegoridhe. Iyi nzira inoshandiswa zvakanyanya mumemory stick uye makadhi emifananidzo.

Latch Gold Fingers: Yakabatanidzwa uchishandisa latches kana zvimwe zvigadziriso zvekusimbisa, zvichipa mamwe ma mechanic fixation, inowanzoshandiswa kumamodule makuru uye maapplication anoda kugadzikana kwakasimba.

Maitiro ekushandisa kweGoridhe Fingers

- Yakakwira Conductivity uye Kugadzikana: Chinhu chikuru chezvigunwe zvegoridhe plating yegoridhe, ine yakanakisa uye yakagadzikana conductivity, ichipa epamusoro magetsi kuita.

- Wear Resistance: Zvikumbiro zvinosanganisira kugara uchiiswa uye kubvisa zvinoda zvigunwe zvegoridhe kuti zvive nekupfeka kwakanaka. Iyo goridhe plating layer inopa dziviriro iyi, kuve nechokwadi kuti zvigunwe zvegoridhe hazvisakara kana kuti oxidize zviri nyore panguva yekushandiswa.

- Corrosion Resistance: Iyo goridhe yeplating layer pazvigunwe zvegoridhe haingopi conductivity asiwo inodzivirira zvinhu zvinoparadza zviri munharaunda, ichiwedzera hupenyu hwezvigunwe zvegoridhe.

Kurongeka kweOptical Modules

1.Zvichienderana nekumhanya kwekufambisa:

10G Optical Modules: Inoshandiswa kune gumi Gigabit Ethernet application.

25G Optical Modules: Yakagadzirirwa 25 Gigabit Ethernet.

40G Optical Modules: Inoshandiswa mu40 Gigabit Ethernet network.

100G Optical Modules: Inokodzera 100 Gigabit Ethernet network.

400G Optical Modules: Yekupedzisira-yepamusoro-kumhanya 400 Gigabit Ethernet application.

2.Kubva pane Transmission Distance:

Short-Range Optical Modules (SR): Kazhinji inotsigira madaro anosvika mazana matatu emamita uchishandisa multimode fiber (MMF).

Yakareba-Range Optical Modules (LR): Yakagadzirirwa madaro anosvika makiromita gumi uchishandisa single-mode fiber (SMF).

Yakawedzerwa Range Optical Modules (ER): Inogona kutumira kusvika kumakiromita makumi mana pamusoro peSMF.

Yakareba Yakareba-Range Optical Modules (ZR): Tsigiro madaro anopfuura makiromita makumi masere pamusoro peSMF.

3.Kubva paWavelength:

850nm Modules: Inowanzo shandiswa kupfupi-renji kutapurirana pamusoro pemultimode fiber.

1310nm Modules: Inokodzera yepakati-renji kutapurirana pane imwe-modhi fiber.

1550nm Modules: Anoshandiswa kutapurirana-refu-refu, kunyanya pamusoro pe-single-mode fiber.

4.Kubva paFomu Factor:

SFP (Small Form-Factor Pluggable): Inowanzoshandiswa kune 1G uye 10G network.

SFP + (Yakawedzerwa Diki Form-Factor Pluggable): Inoshandiswa kune 10G network nepamusoro pekuita.

QSFP (Quad Diki Form-Factor Pluggable): Inokodzera 40G zvikumbiro.

QSFP28: Yakagadzirirwa 100G network, inopa yakakwira density solution.

CFP (C Form-Factor Pluggable): Inoshandiswa mu100G uye 400G zvikumbiro, zvakakura kudarika SFP / QSFP modules.

5.Kubva pane Application:

Data Center Optical Modules: Yakagadzirirwa yakakwirira-kumhanya kufambisa data mukati me data data.

Telecom Optical Modules: Inoshandiswa mune zvekufonera zvivakwa zvekureba-kure data kutapurirana.

Industrial Optical Modules: Yakagadzirirwa nharaunda dzakaomarara, nekupikisa kwakanyanya kusiyanisa tembiricha uye kukanganiswa kwemagetsi.

Nzira yekusiyanisa HDI Nhanho Inoverengera

Kuvigwa Vias: Makomba akaiswa mukati mebhodhi, asingaonekwe kubva kunze.

Mabofu: Makomba anoonekwa nekunze asi asingaone.

Danho Kuverenga: Nhamba yemhando dzakasiyana dzemapofu evhasi, sezvinoonekwa kubva kune imwe mugumo webhodhi, inogona kutsanangurwa sechiverengero chenhanho.

Lamination Count: Nhamba yenguva mapofu/akavigwa vias anopfuura neakawanda cores kana dielectric layer.

Iyo PCB inogadzirwa uchishandisa Panasonic M6 copper-clad laminate

Iyo PCB inogadzirwa uchishandisa Panasonic M6 copper-clad laminate. Isu tine ruzivo rwakakura mundima iyi uye tinoziva mashandisiro akazara kuita kwePanasonic M6 zvinhu nekutarisa kune dzinotevera nzvimbo:

1. Kusarudzwa kwezvinhu uye Kuongorora

Strict Supplier Sarudzo: Sarudza inovimbika uye yakavimbika Panasonic M6 yemhangura-yakapfeka laminate vatengesi kuti ive nechokwadi chakagadzikana uye chakajairwa-chinotevedzera zvinhu. Izvi zvinogona kuitwa nekuongorora zvikwaniriso zvemupi, kugona kwekugadzira, uye masisitimu ekudzora mhando. Makore edu eruzivo akatigonesa kumisa kudyidzana kwenguva refu, kwakagadzikana nevashambadziri vemhando yepamusoro, kuve nechokwadi chemhando yezvinhu kubva kunobva.

Material Inspection: Paunenge wagamuchira iyo copper-clad laminate zvinhu, ita ongororo yakasimba kuti utarise zvakakanganisika senge kukuvadzwa kana mavara uye kuyera maparamendi akadai seukobvu uye hukuru kuti uone kuti anozadzisa zvinodiwa. Yakasarudzika yekuyedza michina inogona zvakare kushandiswa kuyedza zvinhu zvemagetsi zvivakwa, zvinopisa conductivity, uye zvimwe zviratidzo zvekuita kuti ive nechokwadi chekuti zvinosangana nezvinodiwa zvekugadzira. Chikwata chedu chehunyanzvi chekuyedza chinoshandisa michina yemhando yepamusoro uye maitiro akasimba kuti ive nechokwadi chekuti hapana ruzivo rwunoregeredzwa.

2. Dhizaini Optimization

Circuit Layout Dhizaini: Kubva pane hunhu hwePanasonic M6 mhangura-yakapfeka laminate, gadzira dhizaini dhizaini dhizaini zvakakodzera. Kune ma-high-frequency circuits, pfupisa nzira dzechiratidzo kuderedza kuratidzwa kwechiratidzo uye kukanganisa. Kumaseketi emagetsi epamusoro, funga zvizere nyaya dzekupisa kupisa, ronga zvinhu zvekudziya, uye nzira dzekubvisa kupisa nemazvo kuti kuwedzere kupisa kwekupisa kwecopper-clad laminate. Chikwata chedu chedhizaini chinonzwisisa zvivakwa zvePanasonic M6 laminate uye inogona kunyatso dhizaini magadzirirwo zvinoenderana neakasiyana edunhu zvinodiwa.

Stack-Up Dhizaini: Gadzirisa dhizaini yedhizaini-up chimiro zvichienderana nekuoma kwedunhu uye kuita zvinodiwa. Sarudza nhamba yakakodzera yezvikamu, interlayer spacing, uye insulation zvinhu kuti uve nechokwadi chekuvimbika kwechiratidzo uye kugadzikana kwemagetsi. Zvakare, funga kupisa kwekutamisa uye kuparadzira mhedzisiro pakati pematanho kudzivirira kupisa kwenzvimbo. Kuburikidza nekudzidzira kwakawanda uye kuenderera mberi nekugadzirisa, isu takagadzira sainzi uye inonzwisisika stack-up dhizaini mhinduro.

3. Manufacturing Process Control

Etching Maitiro: Nyatsodzora etching paramita kuti ive nechokwadi chechokwadi uye mhando yematanho ebhodhi redunhu. Sarudza etchants akakodzera uye etching mamiriro kuti udzivise kunyanya-etching kana pasi-etching. Pamusoro pezvo, chenjerera kuchengetedza kwezvakatipoteredza panguva yekugadzira nzira yekudzivirira kusvibiswa kwemhangura-yakapfeka laminate. Isu tine ruzivo rwakapfuma mukuita etching maitiro uye tinokwanisa kunyatso kudzora maitiro kuti tive nechokwadi chemhando yebhodhi redunhu.

Kuchera Maitiro: Shandisa yakakwirira-chaiyo yekuchera midziyo uye kutonga kuchera paramita kuti uve nechokwadi chegomba kukura uye kurongeka kwenzvimbo. Kuchengetedza kunofanira kutorwa kuti kurege kukuvadza mhangura-clad laminate, iyo inogona kukanganisa kushanda kwayo. Yedu yepamusoro yekuchera michina uye vane hunyanzvi vanoshanda vanovimbisa kurongeka kwemaitiro ekuchera.

Lamination process: Nyatsodzora lamination paramita kuti ive nechokwadi chekunamatira interlayer uye kushanda kwemagetsi. Sarudza yakakodzera lamination tembiricha, kudzvanywa, uye nguva yekuve nechokwadi chekubatana pakati pemhangura-yakapfeka laminate uye zvimwe zvinodzivirira zvinhu. Zvakare, teerera kune nyaya dzekuneta panguva yelamination process kudzivirira mabubble uye delamination. Kudzora kwedu kwakasimba kweiyo lamination process inovimbisa kugadzikana kuita kwedunhu bhodhi.

4. Quality Testing uye Debugging

Magetsi Ekuita Kuyedzwa: Shandisa yakasarudzika midziyo yekuyedza kuyedza zvimiro zvemagetsi zvedhipatimendi redunhu, zvinosanganisira kuramba, kugona, inductance, insulation kuramba, uye chiratidzo chekufambisa kumhanya. Ita shuwa kuti kushanda kwemagetsi kunosangana nezvinodiwa zvekugadzira uye kuti yakaderera dielectric inogara uye yakaderera dielectric kurasikirwa tangent maitiro ePanasonic M6 copper-clad laminate anoshandiswa zvizere. Yedu yepamusoro uye yakazara yekuyedza michina inogona kuyedza ese maficha emagetsi bhodhi redunhu.

Thermal Performance Testing: Shandisa zvigadziriso zvekufungidzira zvinopisa kuti utarise tembiricha yekushanda yebhodhi redunhu uye tarisa kushanda kwekupisa kupisa. Ita bvunzo dzekuvhundutsa kwekushisa kuti uongorore kugadzikana kwekuita kwebhodhi redunhu pasi pemamiriro ekushisa akasiyana. Yedu yakasimba yekudziya yekupisa performance test inovimbisa kugadzikana kwedunhu bhodhi munzvimbo dzakasiyana dzekushanda.

Debugging uye Optimization: Mushure mekupedza dhizaini bhodhi kugadzira, ita debugging uye optimization. Gadzirisa maparamita edunhu zvichienderana nemhedzisiro yebvunzo kuti uvandudze mashandiro uye kugadzikana kwebhodhi redunhu. Pamusoro pezvo, gara uchipfupikisa zviitiko uye zvidzidzo zvakadzidzwa kuramba uchivandudza magadzirirwo ekugadzira uye dhizaini mhinduro dzekushandisa zvirinani zvakanakira Panasonic M6 copper-clad laminate. Yedu yedebugging uye optimization timu inogona nekukurumidza uye nemazvo kuita debugging kuti irambe ichivandudza kunaka kwechigadzirwa.

Muchidimbu, neruzivo rwedu rwakakura rwekugadzira uye kunzwisisa kwakadzama kwePanasonic M6 copper-clad laminate zvinhu, tine chivimbo mukupa vatengi vedu zvemhando yepamusoro PCB zvigadzirwa.