PCB Surface Qetella

| Surface Finish | Boleng bo Tlwaelehileng | Mofani |

| Lefapha la Boithaopo ba Mollo | 0,3 ~ 0,55um, 0,25 ~ 0,35um | Enthone |

| Shikoku lik'hemik'hale | ||

| DUMELA | Au : 0.03~0.12um, Ni : 2.5~5um | ATO tech/Chuang Zhi |

| Khetho ea ENIG | Au : 0.03~0.12um, Ni : 2.5~5um | ATO tech/Chuang Zhi |

| MOKHOSI | Au : 0.05~0.125um, Pd : 0.05~0.3um, | Chuang Zhi |

| Ka: 3 ~ 10um | ||

| Khauta e Thata | Au : 0.127~1.5um , Ni : min 2.5um | Molefi/EEJA |

| Khauta e Bonolo | Au : 0.127~0.5um , Ni : min 2.5um | EJA |

| Tin ea ho qoelisoa | Min: 1um | Enthone / ATO tech |

| Silivera ea ho qoelisoa | 0.127 ~ 0,45um | Macdermid |

| Keta HASL mahala | 1 ~ 25um | Nihon Superior |

Ka lebaka la 'nete ea hore koporo e teng ka sebopeho sa li-oxide moeeng, e ama ka botebo ho solderability le ts'ebetso ea motlakase ea li-PCB. Ka hona, hoa hlokahala ho phethahatsa pheletso ea li-PCB. Haeba bokaholimo ba li-PCB bo sa phethoa, ho bonolo ho baka mathata a ho soasoa, 'me maemong a boima, lipache tsa solder le likarolo li ke ke tsa rekisoa. Qetello ea bokaholimo ba PCB e bolela mokhoa oa ho etsa lera la bokaholimo ho PCB. Sepheo sa ho qeta PCB ke ho netefatsa hore PCB e na le solderability e ntle kapa ts'ebetso ea motlakase. Ho na le mefuta e mengata ea ho qeta holimo bakeng sa li-PCB.

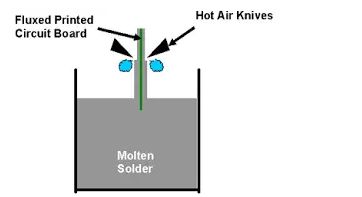

Mocheso oa Solder Leveling (HASL)

Ke ts'ebetso ea ho sebelisa solder e entsoeng ka tšepe e qhibilihisitsoeng holim'a PCB, ho e batalatsa (ho e phethola) ka moea o hatelitsoeng ka mocheso le ho etsa lesela la ho roala le thibelang oxidation ea koporo le ho fana ka solderability e ntle. Nakong ea ts'ebetso ena, hoa hlokahala ho tseba lintlha tse latelang tsa bohlokoa : mocheso oa soldering, mocheso oa thipa ea moea o chesang, khatello ea thipa ea moea o chesang, nako ea ho qoelisoa, ho phahamisa lebelo, joalo-joalo.

Molemo oa HASL

1. Nako e telele ea polokelo.

2. Ho kolobisa pad e ntle le ho koaheloa ka koporo.

3. Mofuta o sebelisoang haholo oa lead free (RoHS compliant).

4. Theknoloji e hōlileng tsebong, theko e tlaase.

5. E loketse haholo bakeng sa tlhahlobo ea pono le tlhahlobo ea motlakase.

Bofokoli ba HASL

1. Ha e loketse ho kopanya mohala.

2. Ka lebaka la meniscus ea tlhaho ea solder e qhibilihisitsoeng, flatness e futsanehile.

3. Ha e sebetse ho li-switches tsa capacitive touch.

4. Bakeng sa liphanele tse tšesaane ka ho khetheha, HASL e ka 'na ea se ke ea tšoaneleha. Mocheso o phahameng oa ho hlapa o ka etsa hore boto ea potoloho e sothe.

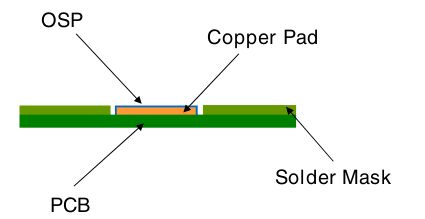

2. Lefapha la Boithaopo ba Mollo

OSP ke khutsufatso ea Organic Solderability Preservative, eo hape e tsejoang e le ka solder. Ka bokhuts'oane, OSP ke hore ho fafatsoa ka holim'a liphahlo tsa koporo solder ho fana ka filimi e sireletsang e entsoeng ka lik'hemik'hale tse phelang. Filimi ena e tlameha ho ba le thepa e kang ho hanyetsa oxidation, ho hanyetsa mocheso oa mocheso le ho hanyetsa mongobo ho sireletsa bokaholimo ba koporo ho tloha mafome (oxidation kapa vulcanization, joalo-joalo) libakeng tse tloaelehileng. Leha ho le joalo, ka mor'a mocheso o phahameng oa mocheso, filimi ena e sireletsang e tlameha ho tlosoa habonolo ke ho phalla ka potlako, e le hore sebaka se pepeneng sa koporo se hloekileng se ka kopana hang-hang le solder e qhibilihisitsoeng ho theha motsoako o matla oa solder ka nako e khutšoanyane haholo. Ka mantsoe a mang, karolo ea OSP ke ho sebetsa joalo ka mokoallo lipakeng tsa koporo le moea.

Molemo oa OSP

1. E bonolo ebile e theko e tlaase; Karolo e ka holimo ke ho roala feela ka spray.

2. Sebaka sa marang-rang sa solder se boreleli haholo, se nang le flatness se bapisoang le ENIG.

3. Ketapele ea mahala (e tsamaellanang le litekanyetso tsa RoHS) ebile e baballa tikoloho.

4. Reworkable.

Bofokoli ba OSP

1. Ho fokola ha metsi.

2. Sebopeho se hlakileng le se tšesaane sa filimi se bolela hore ho thata ho lekanya boleng ka ho hlahloba pono le ho etsa tlhahlobo ea inthanete.

3. Bophelo bo khutšoanyane ba tšebeletso, litlhoko tse phahameng tsa ho boloka le ho tšoara.

4. Tšireletso e fokolang bakeng sa ho kenngoa ka mekoting.

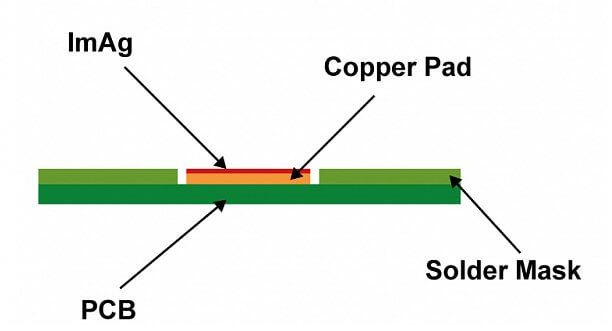

Silivera ea ho qoelisoa

Silevera e na le lik'hemik'hale tse tsitsitseng. The PCB sebetswa ke silevera qoelisoa theknoloji e ntse e ka fana ka tshebetso e ntle ea motlakase esita le ha e pepesehetse mocheso o phahameng, mongobo le tikoloho e silafetseng, hammoho le ho boloka solderability e ntle le haeba e ka lahleheloa ke khanya ea eona. Immersion Silver ke karabelo ea phalliso moo sekala sa silevera se hloekileng se beoang ka kotloloho holim'a koporo. Ka linako tse ling, silevera e qoelisoang e kopantsoe le liphahlo tsa OSP ho thibela silevera ho sebetsana le sulfide tikolohong.

Monyetla oa Silivera ea ho Konoa

1. High solderability.

2. E ntle holim'a flatness.

3. Theko e tlase le lead mahala (e lumellana le litekanyetso tsa RoHS).

4. E sebetsa ho Al terata bonding.

Bofokoli ba ho Inela Silivera

1. Litlhoko tse phahameng tsa polokelo le bonolo ho silafatsoa.

2. Nako e khuts'oane ea fensetere ea kopano ka mor'a ho tsoa ka har'a sephutheloana.

3. Ho thata ho etsa tlhahlobo ea motlakase.

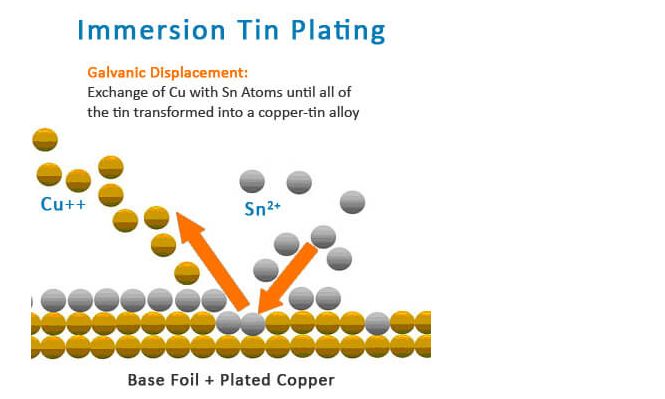

Tin ea ho qoelisoa

Kaha solder eohle e thehiloe ka thini, lesela la thini le ka lumellana le mofuta ofe kapa ofe oa solder. Ka mor'a ho eketsa li-additives ho tharollo ea ho qoelisoa ka thini, mohaho oa lesela la thini o hlahisa sebopeho sa granular, se hlōlang mathata a bakoang ke litelu tsa thini le ho falla ha thini, ha o ntse o e-na le botsitso bo botle ba mocheso le solderability.

Ts'ebetso ea Immersion Tin e ka etsa metsoako ea koporo e sephara ea koporo ea tšepe ho etsa hore tin e qoelisoang e be le solderability ntle le ho sephara kapa mathata a pharalletseng a motsoako.

Molemo oa Tin ea ho Koalloa

1. E sebetsa ho mela ea tlhahiso e otlolohileng.

2. E sebetsa ho ts'ebetso e ntle ea terata le solder e se nang lead, haholo-holo e sebetsang ts'ebetsong ea crimping.

3. Thepa e ntle haholo, e sebetsa ho SMT.

Bofokoli ba Tin ea ho Koalloa

1. Tlhokahalo e phahameng ea polokelo, e ka etsa hore menoana ea menoana e fetole 'mala.

2. Litelu tsa masenke li ka baka li-circuits tse khutšoane le mathata a manonyeletso a solder, ka hona tsa khutsufatsa sethala sa nako.

3. Ho thata ho etsa tlhahlobo ea motlakase.

4. Mokhoa ona o kenyelletsa li-carcinogens.

DUMELA

ENIG (Electroless Nickel Immersion Gold) ke sekoaelo sa holimo se sebelisoang haholo se entsoeng ka likarolo tse peli tsa tšepe, moo nickel e beoang ka kotloloho holim'a koporo ebe liathomo tsa khauta li tšeloa holim'a koporo ka karabelo ea phallo. Botenya ba lesela le ka hare la nickel hangata ke 3-6um, 'me botenya ba bokantle ba khauta hangata ke 0.05-0.1um. Nickel e etsa lera la mokoallo pakeng tsa solder le koporo. Mosebetsi oa khauta ke ho thibela nickel oxidation nakong ea polokelo, kahoo e lelefatsa bophelo ba sethala, empa ts'ebetso ea khauta e qoelisoang e ka boela ea hlahisa bokhabane bo botle ba bokaholimo.

Phallo ea ts'ebetso ea ENIG ke: ho hloekisa-->etching-->catalyst-->chemical nickel plating-->gold deposition-->ho hloekisa masalla

Melemo ea ENIG

1. E loketse soldering ea mahala (RoHS compliant) soldering.

2. Excellent holim'a boreleli.

3. Nako e telele ea lihalalello le sebaka se tšoarellang.

4. E loketse bakeng sa ho kopanya Al terata.

Bofokoli ba ENIG

1. E theko e boima ka lebaka la ho sebelisa khauta.

2. Mokhoa o rarahaneng, o thata ho o laola.

3. Ho bonolo ho hlahisa ketsahalo e ntšo ea pad.

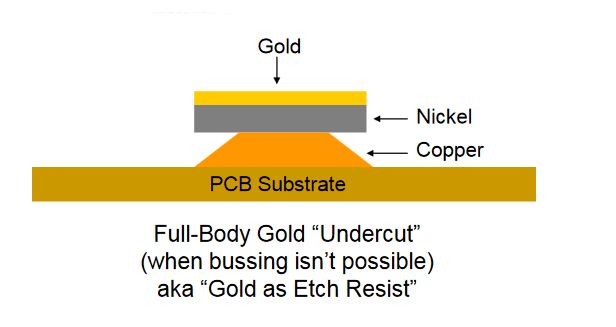

Electrolytic Nickel/Khauta(khauta e thata/khauta e bonolo)

Electrolytic nickel khauta e arotsoe ka "khauta e thata" le "khauta e bonolo". Khauta e thata e na le bohloeki bo fokolang 'me hangata e sebelisoa menoana ea khauta (lihokelo tsa PCB edge), likhokahano tsa PCB kapa libaka tse ling tse sa keneng. Botenya ba khauta bo ka fapana ho ea ka litlhoko. Khauta e bonolo e na le bohloeki bo phahameng 'me hangata e sebelisoa ho kopanya terata.

Monyetla oa Electrolytic Nickel/Gold

1. Bophelo ba shelefo e telele.

2. E loketse bakeng sa phetoho ea ho kopana le ho kopanya mohala.

3. Khauta e thata e loketse tlhahlobo ea motlakase.

4. Lead free (RoHS e lumellana)

Bofokoli ba Electrolytic Nickel/Gold

1. Ka ho fetisisa theko e phahameng holim'a qetello.

2. Electroplating menoana ea khauta e hloka lithapo tse eketsehileng tsa conductive.

3. Ha khauta e na le solderability e fokolang. Ka lebaka la botenya ba khauta, ho thata ho solder lilae tse teteaneng.

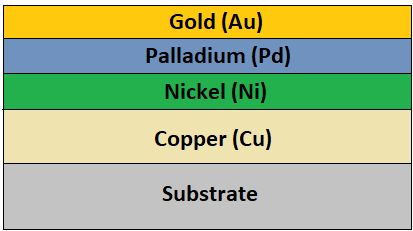

MOKHOSI

Electroless Nickel Electroless Palladium Immersion Gold kapa ENEPIG e ntse e sebelisoa le ho feta bakeng sa ho qeta bokaholimo ba PCB. Ha ho bapisoa le ENIG, ENEPIG e eketsa karolo e 'ngoe ea palladium pakeng tsa nickel le khauta ho sireletsa lesela la nickel hore le se ke la bola le ho thibela ho hlahisa li-pads tse ntšo tse thehang habonolo ts'ebetsong ea ho qetela ea ENIG. Botenya ba nickel bo ka ba 3-6um, botenya ba palladium bo ka ba 0.1-0.5um mme botenya ba khauta ke 0.02-0.1um. Le hoja botenya ba khauta bo le nyane ho feta ENIG, ENEPIG e theko e boima haholo. Leha ho le joalo, ho theoha ha morao tjena ha litšenyehelo tsa palladium ho entse hore theko ea ENEPIG e be bonolo haholoanyane.

Molemo oa ENEPIG

1. E na le melemo eohle ea ENIG, ha ho na ketsahalo e ntšo ea pad.

2. E loketse haholo bakeng sa ho kopanya mohala ho feta ENIG.

3. Ha ho kotsi ea ho bola.

4. Nako e telele ea ho boloka, etella pele mahala (RoHS e lumellana)

Bofokoli ba ENEPIG

1. Mokhoa o rarahaneng, o thata ho o laola.

2. Litšenyehelo tse phahameng.

3. Ke mokhoa o batlang o le mocha 'me ha o e-s'o hōle.