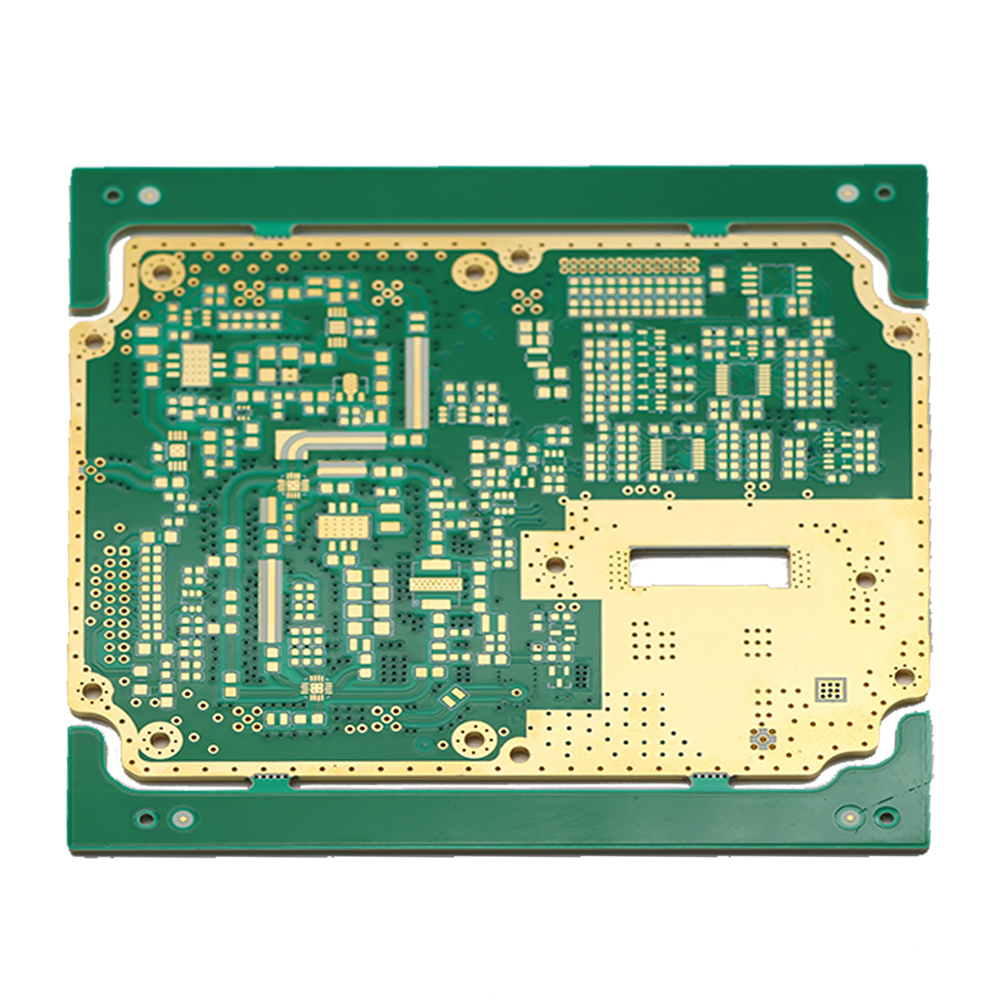

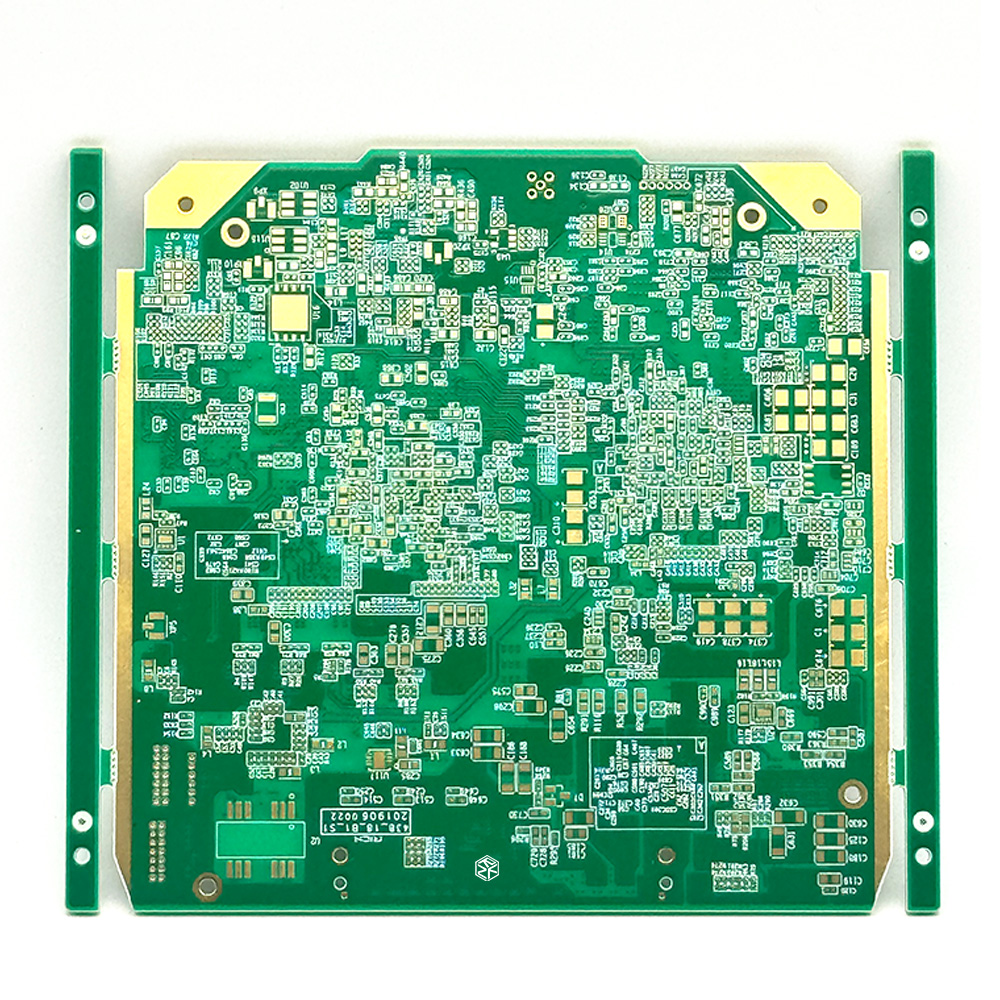

Imodyuli ye-Optical ye-HDI PCB ye-Optical Modyuli yeGolide yeFinger PCB

Imiyalelo yokwenziwa kwemveliso

| Uhlobo | Imigangatho emibini ye-HDI, i-impedance, umngxuma weplagi yeresin |

| Umcimbi | Panasonic M6 Copper-Clad Laminate |

| Inani lomaleko | 10L |

| Ukutyeba kweBhodi | 1.2mm |

| Ubungakanani obunye | 150*120mm/1SET |

| Ukugqitywa komphezulu | INQUNUNU |

| Ubunzima bobhedu lwangaphakathi | 18um |

| Ubukhulu bobhedu lwangaphandle | 18um |

| Umbala wemaski ye-solder | eluhlaza (GTS,GBS) |

| Umbala we-Silkscreen | mhlophe(GTO,GBO) |

| Ngonyango | 0.2mm |

| Ukuxinana komngxuma wokomba oomatshini | 16W/㎡ |

| Ukuxinana komngxuma wokomba welaser | 100W/㎡ |

| Min ngesayizi | 0.1mm |

| Ububanzi bomgca obuncinci/isithuba | 3/3mil |

| Umlinganiselo wokuvula | 9mil |

| Amaxesha oxinzelelo | 3 ixesha |

| Amaxesha okomba | 5 ixesha |

| PN | E240902A |

Amanqaku oLawulo aPhambili kwiMveliso ye-Optical Module HDI Gold Finger PCBs

- I-1, Ulawulo oluchanekileyo lokuFaka i-wiring yeminwe yegolide kunye neePCB ze-HDI zintsonkothe kakhulu, zenza ulawulo lwenkqubo yokubhala ibaluleke kakhulu. I-etching engalunganga inokukhokelela kububanzi bomgca ongalinganiyo, iisekethe ezimfutshane, okanye iisekethe ezivulekileyo. Ngoko ke, kufuneka kusetyenziswe izixhobo ezichanekileyo zokulinganisa, kwaye ukulungelelaniswa rhoqo kuyimfuneko ukuqinisekisa ukuchaneka kunye nokuhambelana kwinkqubo yokubhala.

3, Lamination Control Control Lamination linyathelo elibalulekileyo apho iileya PCB ezininzi zicinezelwe kunye. Ukulawula iqondo lobushushu, uxinzelelo, kunye nexesha ngexesha lamination kubalulekile ukuqinisekisa ukudityaniswa ngokuqinileyo umaleko kunye nobukhulu ibhodi efanayo. I-lamination engalunganga inokubangela i-delamination okanye i-voids, echaphazela ukusebenza kombane kunye namandla omatshini.

4, Ulawulo lweGold Finger Plating Ukutyeba Ubukhulu begolide yokubeka kwiminwe yegolide buchaphazela ngqo ubomi bokufaka kunye nokuthembeka koqhagamshelwano. Ukuba igolide icwecwe kakhulu, inokuphela ngokukhawuleza; ukuba buninzi kakhulu, kwandisa iindleko. Ke ngoko, ngexesha lenkqubo yokubekwa, ixesha lokubekwa kwegolide kunye nokuxinana kwangoku kufuneka kulawulwe ngokungqongqo ukuqinisekisa ukuba ubukhulu beplate budibana nemigangatho (ngokuqhelekileyo i-30-50 microinches).

I-5, Ukulawulwa kokuphazamiseka kunye noVavanyo lwemodyuli ye-Optical HDI PCBs zihlala ziphethe imiqondiso enesantya esiphezulu, zenza ukuba ulawulo lwe-impedance lubaluleke kakhulu. Ngexesha lemveliso, izixhobo zokuvavanya i-impedance kufuneka zisetyenziselwe ukubeka iliso kunye nokulinganisa iimpawu zesignali ezibalulekileyo ngexesha langempela, ukuqinisekisa ukuba i-impedance ingaphakathi kuluhlu loyilo (umzekelo, i-100 ohms). I-impedance engahambelaniyo inokubangela imiba yemfezeko yomqondiso, njengemifanekiso kunye ne-crosstalk.

6.Ukulawulwa koBulunga beSoldering Ngenxa yoxinaniso oluphezulu lwamacandelo abandakanyekayo kwimodyuli ye-optical PCBs, inkqubo ye-soldering kufuneka ichaneke kakhulu. Ukuphinda kufakwe i-solder ephuculweyo kunye nezixhobo zokuthambisa ziyafuneka, kwaye iiprofayili zobushushu bokuthengisa kufuneka zilawulwe ngokungqongqo ukuqinisekisa ukomelela kwamalungu e-solder kunye nokuthembeka koqhagamshelo lombane.

7, Ukucocwa komphezulu kunye noKhuseleko Kwinqanaba ngalinye lemveliso, umphezulu wePCB kufuneka ugcinwe ucocekile ukunqanda uthuli, iminwe, okanye iintsalela ze-oxidation. Ezi ngcoliseko zinokubangela iifutshane zombane okanye zichaphazele umgangatho we-plating. Emva kokuveliswa, iingubo ezifanelekileyo zokukhusela kufuneka zisetyenziswe ukukhusela umswakama kunye nokungcola ekungeneni.

8, Ukuhlolwa koMgangatho kunye noQinisekiso Ukuhlolwa komgangatho obanzi, kubandakanya ukuhlolwa okubonakalayo, uvavanyo lombane, kunye novavanyo olusebenzayo, lubalulekile. Iindlela zokuhlola eziqhelekileyo ziquka uHlolo oluSebenzayo lwe-Optical Inspection (AOI), uvavanyo lwe-flying probe, kunye nokuhlolwa kwe-X-reyi ukuqinisekisa ukuba i-PCB nganye ihlangabezana neenkcukacha zoyilo kunye nemigangatho yomgangatho.

Ukubaluleka komzila kwi-Optical Module HDI PCBs

- Imilinganiselo kunye neSithuba: Ububanzi kunye nezithuba zeminwe yegolide kufuneka zilawulwe ngokungqongqo ukuze kuqinisekiswe ngokufanelekileyo ngokufanelekileyo kunye nezihlanganisi. Ngokuqhelekileyo, ububanzi beminwe yegolide yi-0.5mm, kunye nesithuba se-0.5mm.

- I-Edge Chamfering: I-Chamfering idla ngokufuneka kwincam yePCB apho iminwe yegolide ikhoyo ukuze kube lula ukufakwa okugudileyo kwiindawo zokubeka.

Ukubalwa koMaleko kunye noKupakishwa: IiPCB zeHDI zihlala zibandakanya uyilo lwe-multilayer ukubonelela ngeendlela ezininzi zokuqhagamshelwa kombane. Ubalo lomaleko kunye noyilo lokupakisha kufuneka luqwalaselwe ukuqinisekisa zombini imfezeko yomqondiso kunye nokuthembeka kwamandla.

I-Microvias: Ukusebenzisa ubuchwepheshe be-microvia, obufana ne-vias engaboniyo kunye nokungcwatywa, kunokunciphisa ngokufanelekileyo ubude bonxibelelwano lwe-interlayer, ngaloo ndlela kuncitshiswe ukulibaziseka kunye nokulahlekelwa kwesignali. Ezi microvia zifuna ulawulo oluchanekileyo lwendawo kunye nobukhulu bazo.

Uxinaniso lweendlela: Ngenxa yoxinaniso oluphezulu lweendlela zeebhodi ze-HDI, ingqwalasela eyodwa kufuneka ihlawulwe kububanzi kunye nezithuba zemikhondo. Ngokuqhelekileyo, ububanzi bomkhondo yi-3-4 mil, kwaye isithuba sikwa-3-4 mil.

3.Umqondiso weMfezeko

Iindlela ezimbini ezahlukeneyo: Ukuhanjiswa komqondiso wesantya esiphezulu esiqhele ukusetyenziswa kwiimodyuli ze-optical kufuna iindlela ezimbini ezahlukeneyo zokunciphisa ukuphazamiseka kwe-electromagnetic kunye nokubonakaliswa komqondiso. Ubude kunye nesithuba sezibini ezidityanisiweyo kufuneka zihambelane, ziqinisekise ulawulo lwe-impedance phakathi koluhlu olufanelekileyo (umz., 100 ohms).

Ulawulo lwe-Impedance: Kwindlela yomqondiso wesantya esiphezulu, ulawulo olungqongqo lwe-impedance lubalulekile. Ukuthelekisa i-Impedans kunokufezekiswa ngokulungelelanisa ububanzi bomkhondo, isithuba, kunye nokupakishwa komgangatho.

Ngokusetyenziswa kokusetyenziswa: Ukusetyenziswa kwe-vias kufuneka kuncitshiswe, njengoko bazisa i-parasitic capacitance kunye ne-inductance, echaphazela umgangatho wesignali. Xa kuyimfuneko, ngokufanelekileyo kusetyenziswa iintlobo (ezifana nee-pass ezingaboniyo nezingcwatywayo) kunye neendawo kufuneka zikhethwe.

I-Decoupling Capacitors: Ukubekwa ngokufanelekileyo kwe-decoupling capacitors kunceda ukuzinzisa amandla ombane kunye nokunciphisa ingxolo yamandla.

Uyilo lwePlanethi yoMbane: Ukwamkelwa koyilo lwenqwelomoya yamandla aqinileyo kuqinisekisa ukuhanjiswa okufanayo ngoku kunye nokunciphisa ukuphazamiseka kwe-electromagnetic (EMI).

Ulawulo lwe-Thermal: Ekubeni iimodyuli ze-optical zivelisa ukushisa okukhulu ngexesha lokusebenza, izisombululo zolawulo lwe-thermal kufuneka ziqwalaselwe kuyilo, njengokusebenzisa i-vias ye-thermal, izinto zokuqhuba, okanye i-heat sinks ukunyusa ukusebenza kakuhle kokutshatyalaliswa kobushushu.

6.Ukukhethwa kwezinto

I-Substrate Material: Khetha ii-substrates ezifanelekileyo kwizicelo ze-high-frequency, ezifana ne-polyimide (PI) okanye i-fluoropolymers, ukuqinisekisa ukuhanjiswa komqondiso othembekileyo kunye nozinzile.

Imaski ye-Solder: Sebenzisa ubushushu obuphezulu, ilahleko ephantsi ye-solder imaski yokuqinisekisa ukukhuselwa komkhondo kunye nokusebenza kombane.

IiPCB zeHDI zegolide zeminwe zisetyenziswa ngokubanzi kuwo wonke amasimi ahlukeneyo ngenxa yoxinano oluphezulu kunye neempawu zokusebenza okuphezulu:

5, Izixhobo zonyango: Kwizixhobo zonyango ezifunwa kakhulu njenge-CT scanners, oomatshini be-MRI, kunye nezinye izixhobo zokuxilonga, iiPCB zegolide ze-HDI ziqinisekisa ukuhanjiswa kwedatha echanekileyo kunye nokusebenza okuthembekileyo kwezixhobo.

- I-6, i-Aerospace: Ezi PCB zisetyenziswa kwiinkqubo zokulawula i-satellites, i-aircraft, kunye ne-spacecraft, njengoko zikwazi ukumelana neemeko ezinzima zokusingqongileyo ngelixa zigcina ukusebenza okuphezulu.

- 7

Umnwe wegolide

Intshayelelo eneenkcukacha kwiMinwe yeGolide

Iminwe yegolide ibhekisela kwiindawo ezifakwe ngegolide kumda webhodi yesekethe eprintiweyo (PCB). Ngokuqhelekileyo zisetyenziselwa ukwenza uqhagamshelwano lombane kunye nezihlanganisi. Igama elithi "umnwe wegolide" livela kwinkangeleko yabo: amacandelo afana negolide afana neminwe. Iminwe yegolide idla ngokusetyenziswa kwiiPCB ezifakelwayo, ezifana nezinti zememori, amakhadi emizobo, kunye nezinye izixhobo, ukudibanisa neendawo zokubeka. Umsebenzi ophambili weminwe yegolide kukubonelela ngoqhagamshelo lombane oluthembekileyo ngokusebenzisa umaleko wegolide osebenza kakhulu ngelixa uqinisekisa ukuxhathisa ukunxiba kunye nokuxhathisa umhlwa.

Ukuhlelwa kweMinwe yeGolide

Iminwe yegolide inokuhlelwa ngokusekelwe kumsebenzi wabo, isikhundla, kunye nenkqubo yokuvelisa:

UQhagamshelwano loMbane lweMinwe yeGolide: Le minwe yegolide isetyenziswa ikakhulu ukubonelela ngoqhagamshelo lombane oluzinzileyo, olufana neenkumbulo, amakhadi emizobo, kunye nezinye iimodyuli zeplagi. Bahambisa imiqondiso yombane ngokufakwa kwiindawo zokubeka kwi-motherboard okanye ezinye izixhobo.

I-Power Supply Gold Fingers: Ezi zisetyenziselwa ukubonelela ngamandla okanye ukudibanisa ukudibanisa, ukuqinisekisa ukuba izixhobo zifumana igalelo lamandla azinzileyo.

2.Ngokusekelwe kwiNdawo:

Iminwe yegolide ye-Edge: Ngokuqhelekileyo ibekwe ekupheleni kwe-PCB, isetyenziselwa uxhulumaniso lwe-slot kwaye ixhaphake ngokufunyanwa kwimemori yememori, amakhadi emifanekiso, kunye neemodyuli zonxibelelwano. Olu lolona hlobo luqhelekileyo lomnwe wegolide.

Iminwe yeGolide engeyiyo eEdge: Le minwe yegolide ayibekwanga kumda wePCB kodwa ibekwe ngaphakathi kuqhagamshelo okanye imisebenzi ethile, njengamanqaku ovavanyo okanye uqhagamshelo lwemodyuli yangaphakathi.

3.Ngokusekwe kwiNkqubo yokuVelisa:

Ukuntywiliselwa kweMinwe yeGolide: Ezi zidalwa kusetyenziswa inkqubo yokubeka imichiza ukuze kufakwe umaleko wegolide kwifoyile yobhedu. Zinomgangatho ogudileyo, ocolekileyo kodwa umaleko wegolide ocekethekileyo, oqhele ukusetyenziselwa uqhagamshelo lombane olunesantya esisezantsi.

Iminwe yeGolide ene-Electroplated: Yenziwe kusetyenziswa inkqubo yokufakwa kwe-electroplating, le minwe yegolide inomaleko wegolide ongqindilili kwaye ayigugi ngakumbi, ilungele ukudityaniswa kombane okuthembeke kakhulu okudinga ukufakwa rhoqo kunye nokususwa, njengakwimemori sticks kunye namakhadi emizobo. Le nkqubo isebenzisa ubukhulu begolide obuyi-30-50 microinches ukuqinisekisa ukuqina kunye nokuhamba kakuhle.

4.Ngokusekwe kwiNdlela yoQhagamshelwano:

Faka iMinwe yeGolide ngokuthe ngqo: Ifakwe ngokuthe ngqo kwi-slot, i-slot's elasticity ibamba iminwe yegolide. Le ndlela isetyenziswa kakhulu kwimemori sticks kunye namakhadi emizobo.

I-Latch Gold Fingers: Idibaniswe kusetyenziswa iilatshi okanye ezinye izixhobo zokuzibophelela, ukubonelela ngolungiso olongezelelweyo lomatshini, olusetyenziswa ngokuqhelekileyo kwiimodyuli ezinkulu kunye nezicelo ezifuna uxhulumaniso oluzinzile.

Iimpawu zeSicelo seMinwe yeGolide

- I-High Conductivity kunye nokuzinza: Izinto eziphambili zeminwe yegolide yi-plating yegolide, ene-conductivity egqwesileyo kwaye ezinzileyo, enikezela ukusebenza kombane okuphezulu.

- I-Wear Resistance: Ukusetyenziswa okubandakanya ukufakwa rhoqo kunye nokususwa kufuna iminwe yegolide ibe nokuxhathisa okulungileyo kokunxiba. Umaleko wegolide owenziweyo unika olu khuselo, uqinisekisa ukuba iminwe yegolide ayigugi okanye ikhuphe ioksijini ngokulula xa isetyenziswa.

- Ukumelana neCorrosion: Umaleko wegolide ocwebezelayo kwiminwe yegolide awuboneleli nje ngokuqhuba kodwa ukwaxhathisa izinto ezitshabalalisayo kwindalo esingqongileyo, ukwandisa ixesha lokuphila kweminwe yegolide.

Ukuhlelwa kweeModyuli ze-Optical

1.Ngokusekwe kwisantya soThutho:

Iimodyuli ze-10G Optical: Isetyenziselwa izicelo ze-10 Gigabit Ethernet.

Iimodyuli ze-25G Optical: Yenzelwe i-25 Gigabit Ethernet.

Iimodyuli ze-40G ze-Optical: Isetyenziswe kwiinethiwekhi ze-40 Gigabit Ethernet.

I-100G Iimodyuli ze-Optical: Ifanelekile kwi-100 Gigabit Ethernet networks.

Iimodyuli ze-400G ze-Optical: Kwi-ultra-high-speed 400 ye-Gigabit Ethernet izicelo.

2.Ngokusekwe kumgama woThumelo:

IiModyuli eziMfutshane ze-Optical (SR): Ngokuqhelekileyo zixhasa umgama ukuya kwi-300 yeemitha usebenzisa i-multimode fiber (MMF).

Iimodyuli zoLunge olude lwe-Optical (LR): Yenzelwe umgama ukuya kwiikhilomitha ezili-10 kusetyenziswa i-fiber ye-single-mode (SMF).

Iimodyuli ezongeziweyo zeRange Optical (ER): Inokuhambisa ukuya kwiikhilomitha ezingama-40 ngaphezulu kwe-SMF.

IiModyuli eziLude kakhulu zoLudwe oluLude kakhulu (i-ZR): Inkxaso yomgama ongaphezu kweekhilomitha ezingama-80 ngaphezulu kwe-SMF.

3.Ngokusekwe kwiWavelength:

Iimodyuli ze-850nm: Ngokuqhelekileyo zisetyenziselwa ukuhanjiswa kwexesha elifutshane kwi-multimode fiber.

Iimodyuli ze-1310nm: Ilungele ukuhanjiswa koluhlu oluphakathi kwifiber yendlela enye.

Iimodyuli ze-1550nm: Isetyenziselwa ukuhanjiswa kwexesha elide, ngakumbi ngaphezulu kwefayibha yemowudi enye.

4.Ngokusekwe kwiFom Factor:

I-SFP (I-Small Form-Factor Pluggable): Ngokuqhelekileyo isetyenziselwa i-1G kunye ne-10G inethiwekhi.

I-SFP + (I-Enhanced Small Form-Factor Pluggable): Isetyenziselwa amanethiwekhi e-10G kunye nokusebenza okuphezulu.

I-QSFP (i-Quad Small-Factor Pluggable): Ifanelekile kwizicelo ze-40G.

I-QSFP28: Yenzelwe iinethiwekhi ze-100G, ezinikezela ngesisombululo esiphezulu soxinaniso.

I-CFP (i-C Form-Factor Pluggable): Isetyenziswe kwi-100G kunye ne-400G izicelo, ezinkulu kuneemodyuli ze-SFP / QSFP.

5.Ngokusekwe kwisicelo:

Iimodyuli zeZiko leeNkcukacha: Yenzelwe ukuhanjiswa kwedatha yesantya esiphezulu ngaphakathi kwamaziko edatha.

Iimodyuli ze-Telecom Optical: Isetyenziswa kwiziseko zonxibelelwano ngefowuni yokuhanjiswa kwedatha kumgama omde.

Iimodyuli ze-Industrial Optical: Yakhelwe iindawo ezinqabileyo, ezinokumelana okuphezulu nokwahluka kobushushu kunye nokuphazamiseka kwe-electromagnetic.

Indlela Yokwahlula HDI Inyathelo Ibala

Indlela yokuNgcwaba: Imingxuma efakwe ngaphakathi kwebhodi, ingabonakali ngaphandle.

Iindlela ezingaboni ngasonye: Imingxuma ebonakalayo ngaphandle kodwa ayiboni ngaphaya.

Ubalo lwenyathelo: Inani leentlobo ngeentlobo zeendlela ezingaboniyo, njengoko zijongwa ukusuka kwelinye icala lebhodi, zinokuchazwa njengobalo lwamanyathelo.

Ubalo lokuLamination: Inani lamaxesha okufameka/okungcwatywayo kudlula kwiicores ezininzi okanye iileya zedielectric.

I-PCB yenziwe kusetyenziswa i-Panasonic M6 i-copper-clad laminate

I-PCB yenziwe kusetyenziswa i-Panasonic M6 i-copper-clad laminate. Sinamava abanzi kule ndawo kwaye siyayazi indlela yokusebenzisa ngokupheleleyo ukusebenza kwePanasonic M6 imathiriyeli ngokugxila kwezi ndawo zilandelayo:

1. Ukukhethwa kwezinto kunye nokuHlola

Ukukhetha okungqongqo koMboneleli: Khetha abanikezeli be-laminate abathembekileyo nabathembekileyo be-Panasonic M6 yobhedu ukuze uqinisekise izinto ezizinzileyo nezisemgangathweni. Oku kunokwenziwa ngokuvavanya iziqinisekiso zomthengisi, umthamo wemveliso, kunye neenkqubo zokulawula umgangatho. Iminyaka yethu yamava isenze ukuba sikwazi ukuseka ubudlelwane bexesha elide, oluzinzileyo kunye nabanikezeli bekhwalithi ephezulu, ukuqinisekisa umgangatho wezinto eziphathekayo ezivela kumthombo.

Ukuhlolwa kwezinto eziphathekayo: Emva kokufumana izinto ezifihliweyo zobhedu, qhuba uhlolo olungqongqo ukujonga iziphene ezifana nomonakalo okanye amabala kunye nokulinganisa iiparitha ezifana nobukhulu kunye nobukhulu ukuqinisekisa ukuba ziyahlangabezana neemfuno. Izixhobo zokuvavanya ezikhethekileyo zingasetyenziselwa ukuvavanya iipropati zombane zezinto eziphathekayo, ukuqhutyelwa kwe-thermal, kunye nezinye iimpawu zokusebenza ukuqinisekisa ukuba ziyahlangabezana neemfuno zoyilo. Iqela lethu lovavanyo lobuchwephesha lisebenzisa izixhobo eziphambili kunye neenkqubo ezingqongqo zokuqinisekisa ukuba akukho zinkcukacha zingahoywayo.

2. ULungiselelo loYilo

I-Circuit Layout Design: Ngokusekelwe kwiimpawu ze-Panasonic M6 i-copper-clad laminate, yila ibhodi yesiphaluka ngokufanelekileyo. Kwiisekethe eziphezulu ze-frequency, nciphisa iindlela zesignali ukunciphisa ukubonakalisa umqondiso kunye nokuphazamiseka. Kwiisekethe zamandla aphezulu, qwalasela ngokupheleleyo imiba yokutshatyalaliswa kobushushu, cwangcisa izinto zokufudumeza, kunye nemijelo yokutshatyalaliswa kobushushu ngokufanelekileyo ukuze ukwandise ukuqhutyelwa kwe-thermal ye-laminate ye-copper-clad. Iqela lethu loyilo liyaziqonda iipropathi zePanasonic M6 laminate kwaye inokwakheka ngokuchanekileyo uyilo ngokweemfuno zesekethe ezahlukeneyo.

Uyilo lwe-Stack-Up: Lungiselela ukwakheka kwebhodi yesekethe ngokusekwe kububunzima besekethe kunye neemfuno zokusebenza. Khetha inani elifanelekileyo leeleya, isithuba se-interlayer, kunye nezixhobo zokugquma ukuze uqinisekise imfezeko yomqondiso kunye nokuzinza kombane. Kwakhona, qwalasela ukutshintshwa kobushushu kunye nemiphumo yokulahla phakathi kweeleya ukuphepha ukufudumeza kwendawo. Ngokuziqhelanisa ngokubanzi kunye nokwandisa okuqhubekayo, siye saphuhlisa isisombululo soyilo lwenzululwazi kunye nesingqindilili esifanelekileyo.

3. Ulawulo lweNkqubo yokuVelisa

Inkqubo ye-Etching: Ukulawula ngokuchanekileyo iiparameters zokudibanisa ukuqinisekisa ukuchaneka kunye nomgangatho weempawu zebhodi yesekethe. Khetha ii-etchants ezifanelekileyo kunye neemeko zokurhweba ukunqanda ukurhabula kakhulu okanye ukurhawuzelelwa ngaphantsi. Ukongezelela, khumbula ukukhuselwa kwendalo ngexesha lenkqubo yokuthintela ukuthintela ukungcoliswa kwe-laminate yobhedu. Sinamava atyebileyo kwiinkqubo ze-etching kwaye sinokulawula ngokuchanekileyo inkqubo yokuqinisekisa umgangatho webhodi yesekethe.

Inkqubo yokugaya: Sebenzisa izixhobo zokugaya ezichanekileyo eziphezulu kunye nokulawula iiparitha zokuqhuba ukuqinisekisa ubungakanani bomngxuma kunye nokuchaneka kwendawo. Ukunyamekela kufuneka kuthathwe ukuphepha ukulimaza i-laminate ye-copper-clad, enokuchaphazela ukusebenza kwayo. Izixhobo zethu eziphambili zokuqhuba kunye nabaqhubi abanezakhono baqinisekisa ukuchaneka kwenkqubo yokugaya.

Inkqubo yokuLamination: Lawula ngokungqongqo iiparamitha ze-lamination ukuqinisekisa ukunamathela kwe-interlayer kunye nokusebenza kombane. Khetha ubushushu obufanelekileyo be-lamination, uxinzelelo, kunye nexesha lokuqinisekisa ukuhlangana okuhle phakathi kwe-laminate ene-copper-clad kunye nezinye izinto zokukhusela. Kwakhona, nikela ingqalelo kwimiba yokukhupha ngexesha lenkqubo yokuthambisa ukuze ugweme amaqamza kunye ne-delamination. Ulawulo lwethu olungqongqo lwenkqubo ye-lamination luqinisekisa ukusebenza okuzinzile kwebhodi yesekethe.

4. UVavanyo loMgangatho kunye nokulungiswa kweempazamo

Uvavanyo lokuSebenza koMbane: Sebenzisa izixhobo zovavanyo ezikhethekileyo ukuvavanya iimpawu zombane zebhodi yesekethe, kubandakanya ukumelana, amandla, inductance, ukumelana nokugquma, kunye nesantya sokuhambisa umqondiso. Qinisekisa ukuba ukusebenza kombane kuhlangabezana neemfuno zoyilo kunye nokuba i-dielectric ephantsi rhoqo kunye nelahleko ephantsi ye-dielectric iimpawu ze-tangent ze-Panasonic M6 ze-copper-clad laminate zisetyenziswa ngokupheleleyo. Izixhobo zethu zokuvavanya eziphambili kunye nezibanzi zinokuvavanya yonke imiba yokusebenza kombane webhodi yesekethe.

Uvavanyo lweNtsebenzo ye-Thermal: Sebenzisa izixhobo zokucinga ze-thermal ukujonga ukushisa okusebenzayo kwebhodi yesiphaluka kunye nokujonga ukusebenza kokutshatyalaliswa kobushushu. Yenza iimvavanyo zokutshatyalaliswa kwe-thermal ukuvavanya ukuzinza kokusebenza kwebhodi yesekethe phantsi kweemeko ezahlukeneyo zokushisa. Uvavanyo lwethu olungqongqo lwentsebenzo ye-thermal luqinisekisa ukuzinza kwebhodi yesekethe kwiindawo ezahlukeneyo zokusebenza.

Ukulungiswa kweempazamo kunye nokuPhuculwa: Emva kokugqiba ukuveliswa kwebhodi yesekethe, yenza ukulungiswa kunye nokuphucula. Lungisa iiparamitha zesekethe ngokusekelwe kwiziphumo zovavanyo ukuphucula ukusebenza kunye nokuzinza kwebhodi yesekethe. Ukongeza, hlala ushwankathela amava kunye nezifundo ezifundiweyo ukuze uqhubeke uphucula iinkqubo zokuvelisa kunye nezisombululo zoyilo lokusebenzisa ngcono izibonelelo zePanasonic M6 copper-clad laminate. Iqela lethu lokulungisa iimpazamo kunye neqela lokuphucula linokuqhuba ngokukhawuleza nangokuchanekileyo ukulungisa ingxaki ngokuqhubekayo ukuphucula umgangatho wemveliso.

Isishwankathelo, ngamava ethu abanzi okuvelisa kunye nokuqonda okunzulu kwePanasonic M6 yobhedu-clad laminate, siqinisekile ngokubonelela abathengi bethu ngeemveliso eziphezulu zePCB.