Uyawazi umsebenzi we-PCB solder mask? Yiziphi izinketho ze-PCB solder mask?

I-IPC isungule indinganiso yokuhlola imaski ye-solder njengomhlahlandlela womkhakha wabakhiqizi bezinto ezibonakalayo, ama-OEM, nabakhiqizi be-PCB. I-IPC SM-840D ihlukanisa izendlalelo zemaski ezithengiswayo, Ikilasi T kanye Nekilasi H, elifingqiwe kanje:

I-T-Telecommunications: okuhlanganisa amakhompuyutha, okokusebenza kwezokuxhumana, imishini yezentengiselwano eyinkimbinkimbi, amathuluzi kanye nezinhlelo ezithile zezempi ezingabalulekile. Isendlalelo semaski ye-solder kulolu hlobo lwebhodi lesifunda lufanele imikhiqizo yezohwebo neyezimboni esebenza kahle kakhulu edinga impilo yesevisi enwetshiwe kodwa engafaki ukuphila engozini uma isevisi iphazamiseka.

H - Ukuthembeka okuphezulu/ezempi: okuhlanganisa ukusebenza okuqhubekayo okubalulekile, isikhathi sokuphumula semishini esingabekezeleleki, kanye/noma okokusebenza okuyiprojekthi yokusekela impilo. Isendlalelo semaski ye-solder kulolu hlobo lwebhodi lesifunda lufanele izinhlelo zokusebenza ezidinga ukuqinisekiswa kwezinga eliphezulu kanye nesevisi engaphazamiseki.

Uyawazi umsebenzi we-PCB solder mask?

1. Ibambezela inqubo yokuguga:Vimbela ukulimala kwama-PCB okubangelwa imisebe ye-ultraviolet, yehlisa izinga lokuguga lezinto ezibonakalayo, ikakhulukazi amabhodi esekethe achayeka ezindaweni ezingaphandle noma eziqinile zokukhanya isikhathi eside. Imaski ye-Solder ingakha ifilimu yokuvikela ku-PCB, ivikele isifunda emonakalweni wangaphandle, uthuli, umswakama, nezinto zamakhemikhali, futhi yandise impilo yesevisi yebhodi lesifunda.

2. Ukuvikelwa kwe-insulation: Isendlalelo semaski ye-solder sinokusebenza okuhle kokufakwa. Ngokuyimboza ngokunembile ezindaweni ezingashisi, imaski ye-solder ingakwazi ukuhlukanisa ngokuphumelelayo amasekhethi ahlukahlukene ebhodini lesifunda, igweme izifunda ezimfushane namaphutha kagesi ngesikhathi senqubo yokuhlanganisa, igweme umonakalo ongase ube khona wesifunda, futhi ithuthukise ukusebenza kukagesi nokuphepha komkhiqizo.

3. Thuthukisa izinga le-solder: Imaski ye-solder ingavimbela i-solder ukuthi ingasakazeki ezindaweni ezingadingi ukufakwa kwe-solder, iqinisekisa ukuhlanzeka nokunemba kwendawo yokunamathisela. Lokhu kusiza ekuthuthukiseni izinga le-soldering nokunciphisa amaphutha okukhiqiza.

4. Thuthukisa ukubukeka:Imaski ye-Solder yenza indawo ebushelelezi nefanayo ku-PCB, engagcini nje ngokujabulisa ubuhle kodwa futhi elungele ukulebula okulandelayo, ukuphrinta nezinye izinqubo, ithuthukisa ikhwalithi yokubukeka iyonke yomkhiqizo.

5. Ukusebenza kwe-insulation okuthuthukisiwe:Isendlalelo semaski ye-solder sinokusebenza okuhle kokufakelwa, okungathuthukisa ukufakwa kukagesi kwe-PCB, kunciphise amathuba okuvuza nokuphazamiseka kukagesi, futhi kuqinisekise ukusebenza okuvamile kwesekethe.

6. Ukwenza lula ukuhlola:Ngesikhathi senqubo yokukhiqiza ye-PCB, isendlalelo semaski ye-solder singavikela umjikelezo emishinini eyimishini efana nezikhonkwane zokuhlola, kuyilapho kusiza ukuhlolwa kokufakwa kwephinikhodi nokuhlola okubukwayo, ukuthuthukisa ukusebenza kahle kokuhlola nokunemba.

7. Ukuvikelwa Kwemvelo kanye Nokuhambisana Namazinga:Imaski yesimanje solder ngokuvamile ihambisana ROHS (Restriction of the Use of Certain Hazardous Substances Directive) kanye nezinye izindinganiso zemvelo, okusiza ukunciphisa umthelela wemfucuza ye-elekthronikhi emvelweni kanye nokuhlangabezana nezidingo zemakethe yamazwe ngamazwe.

8. Lungiselela ukusebenza kokukhipha ukushisa:Nakuba lokhu kungewona umsebenzi oqondile we-mask ye-solder, ngokuklama okunengqondo, njengokugwema noma ukunciphisa izendlalelo ze-solder mask ezindaweni ezibucayi zokushisa ukushisa, ukusebenza kokukhipha ukushisa kwama-PCB kungathuthukiswa.

Ngakho-ke, imaski ye-solder efanelekile nesezingeni eliphezulu ingathuthukisa kakhulu ukwethembeka nempilo yesevisi yama-PCB. Ukukhetha ngokucophelela kanye nokusetshenziswa kwe-mask solder ekuklanyeni nasekukhiqizeni amabhodi wesifunda kungenye yezinyathelo ezibalulekile zokuqinisekisa ukusebenza okuzinzile kwesikhathi eside kwamabhodi wesifunda.

Uyazi ukuthi yiziphi izinketho ze-PCB solder mask?

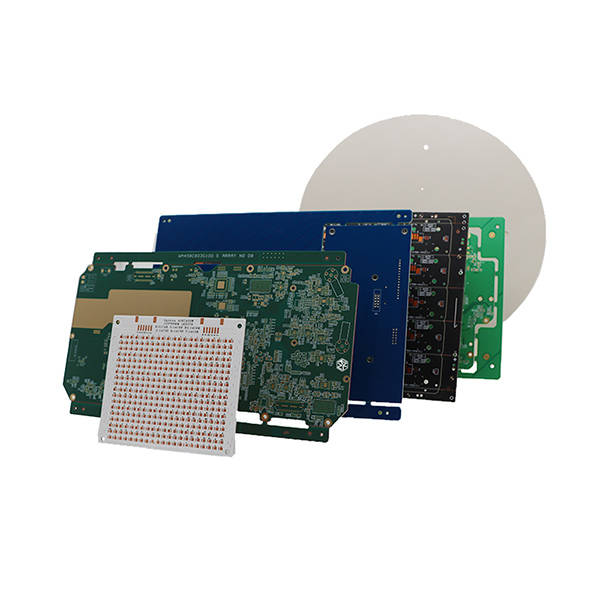

Isendlalelo semaski ye-solder eluhlaza

Imaski ye-solder eluhlaza ibilokhu iyinketho ethandwayo yemaski ye-PCB ngoba ivumela yonke into ukuthi ibonakale ngokucacile. Isendlalelo semaski esiluhlaza sinomehluko omuhle phakathi kwezindawo ezinethusi nezingenayo ngezansi kwesendlalelo semaski ye-solder. Ungabona kalula amamaki ngamehlo akho, kodwa ngongqimba lwamaski omnyama we-solder - awazi.

Isendlalelo semaski esimhlophe

Ukusetshenziswa kongqimba lwemaski emhlophe kuya ngokuya kuthandwa kakhulu ngoba umhlophe ungenza ama-PCB abukeke emuhle kakhulu endaweni ehlanzekile. Kodwa-ke, isendlalelo semaski esimhlophe sifihla ngempumelelo iminonjana. Kwezinye izimo, ukuhlola okubukwayo cishe akunakwenzeka, ikakhulukazi uma usegumbini elinokukhanya okungaphezulu kuphela.

Isendlalelo semaski esimnyama

Uma kuqhathaniswa nenketho emhlophe, isendlalelo semaski esimnyama sinikeza ama-PCB ukubukeka okuphezulu nochwepheshe, okunikeza ngokubonakalayo inani eliqinile lobuchwepheshe nobuhle bemikhiqizo, elungele ikakhulukazi imikhiqizo ye-elekthronikhi yabathengi enezidingo eziphezulu zokubukeka.

Kuyaqapheleka ukuthi isendlalelo semaski esimnyama solder sibuye sibe nezinselelo ezithile. Ngenxa yokumunca ukukhanya okuphezulu, ama-PCB amnyama angase athambekele kakhulu ekumunceni ukushisa ngesikhathi senqubo yokukhiqiza, okungase kuholele ekucindezelekeni okushisayo ezimeni ezithile futhi adinge ukulawula phakathi nenqubo yokuklama neyokukhiqiza. Ngaphezu kwalokho, isendlalelo semaski esimnyama sinamandla anamandla okufihla amaphutha angaphakathi kuma-PCB, ngakho-ke amazinga aphezulu kanye nezinyathelo eziqinile zokulawula ikhwalithi kufanele zamukelwe ezinqubweni zokukhiqiza nezokuhlola.

Isendlalelo semaski esibomvu solder

Ukukhetha ungqimba lwemaski ye-solder ebomvu nakho kudinga ukucatshangelwa kwezinye izici. Isendlalelo semaski esibomvu se-solder singabonisa ngokuqhathaniswa imininingwane yamaphoyinti okushisela namasekhethi, okwenza kube lula ukuhlonza izinkinga ekuhlolweni kokukhiqiza kanye nokulungiswa kamuva. Imibala yayo ekhanyayo iphinde isize ukuthuthukisa izinga lokuthola amaphutha ezinqubweni zokuhlola (i-AOI). Isibonelo, uma kuqhathaniswa nezingqimba zamamaski ezimnyama (ezifana nokumnyama nokuluhlaza), okubomvu kungase kube nekhono elibuthaka kancane lokufihla amaphutha angaphakathi kwezinye izimo, okungase kube nomthelela othile kubuhle obubonakalayo bamabhodi wesekethe. Ngesikhathi esifanayo, ezindaweni ezithile zohlelo lokusebenza, abasebenzisi badinga futhi ukucabangela izici ezifana nokuzinza ngokomzimba namakhemikhali we-mask solder.

Isendlalelo semaski esiluhlaza okwesibhakabhaka

Ibhodi lesifunda elinamalebula asindayo kufanele licabangele ukusebenzisa isendlalelo semaski esiluhlaza okwesibhakabhaka, njengoba sakha umehluko ocacile nokuphrinta kwesikrini. Uma kungekho ukukhanya nokukhulisa okufanele, izimpawu ezingaphansi kongqimba lwemaski ye-solder eluhlaza okwesibhakabhaka kuzoba nzima kakhulu ukuzibona. Uma iqhathaniswa neminye imibala, ijwayele ukungcola.

Isendlalelo semaski esiphephuli

Imibala eminingi emisha iyavela, kodwa kungase kube nzima ukuyiphatha. Kwesinye isikhathi, amaqoqo ahlukene okukhiqiza angakhombisa umehluko ocashile. Ophuzi nowolintshi imibala ejabulisayo, kodwa umehluko wabo ekuphrinteni kwesikrini nokulandela umkhondo kufana nechibi lokubhukuda. Isendlalelo semaski esimpunga sivame ukucatshangelwa amabhodi wesifunda aphrintiwe we-LED/amaphrojekthi e-PCB e-aluminium.

Isendlalelo semaski esicwebezelayo esinemibala ecwebezelayo

Imibala ehlukene izolinganisa izidingo ezihlukene, njengokuhlanzeka, ukubonakala, nesitayela. Ngaphambi kokuqala ukukhiqizwa ngobuningi bemibala emisha, ungazama njalo amasampula nathi.

Ngaphambi kokuzama idizayini elandelayo ye-PCB, sikwamukela ngokufudumele ukuthi uxhumane nabasebenzi bethu bokuthengisa ukuze uthole amasampula wamahhala - ungawasebenzisa njengesithenjwa. Abahlinzeki bethu abakhulu beyinki yemaski ye-solder bahlanganisa i-Taiyo Japan, i-Taiyo USA, ne-Taiyo Suzhou.