I-PCB Surface Finish

| I-Surface Qeda | Inani Elijwayelekile | Umphakeli |

| UMnyango Wezomlilo Wokuzithandela | 0.3 ~ 0.55um, 0.25 ~ 0.35um | Enthone |

| Shikoku chemical | ||

| VUMA | Noma : 0.03~0.12um, Ni : 2.5~5um | I-ATO tech/Chuang Zhi |

| I-ENIG ekhethiwe | Noma : 0.03~0.12um, Ni : 2.5~5um | I-ATO tech/Chuang Zhi |

| UTHISHANHLOKO | Noma : 0.05~0.125um, Pd : 0.05~0.3um, | Chuang Zhi |

| Ku: 3 ~ 10um | ||

| Igolide Eliqinile | Noma : 0.127~1.5um , Ni : min 2.5um | Umkhokhi/EEJA |

| Igolide Elithambile | Noma : 0.127~0.5um , Ni : min 2.5um | EJA |

| I-Tin yokucwiliswa | Ubuncane: 1um | I-Enthone / ATO tech |

| Isiliva Sokucwiliswa | 0.127~0.45um | I-Macdermid |

| Ukuhola i-HASL yamahhala | 1 ~ 25 um | Nihon Superior |

Ngenxa yokuthi ithusi likhona ngesimo sama-oxides emoyeni, lithinta kakhulu ukuthengiswa nokusebenza kukagesi kwama-PCB. Ngakho-ke, kuyadingeka ukwenza isiphetho esingaphezulu sama-PCB. Uma ingaphezulu lama-PCB lingaqediwe, kulula ukubangela izinkinga zokudayiswa kwe-virtual, futhi ezimweni ezinzima, amaphedi e-solder nezingxenye azikwazi ukuthengiswa. I-PCB surface finish isho inqubo yokwenza ungqimba lwangaphezulu ngokuzenzakalelayo ku-PCB. Inhloso yokuqeda i-PCB ukuqinisekisa ukuthi i-PCB inokuthengiselana okuhle noma ukusebenza kukagesi. Kunezinhlobo eziningi zokuqeda okungaphezulu kwama-PCB.

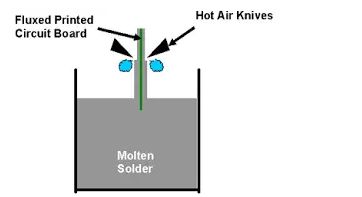

I-Hot Air Solder Leveling (HASL)

Kuyinqubo yokufaka i-solder encibilikisiwe ye-tin lead ebusweni be-PCB, ukuyibeka phansi (ukuyiphephetha) ngomoya ocindezelwe oshisayo futhi kwakhiwe ungqimba lokumboza olukwazi ukumelana ne-oxidation yethusi futhi lunikeze ukuthengiselana okuhle. Phakathi nale nqubo, kuyadingeka ukwazi kahle imingcele ebalulekile elandelayo : ukushisa kwe-soldering, ukushisa kommese womoya oshisayo, ukucindezela kommese womoya oshisayo, isikhathi sokucwiliswa, isivinini sokuphakamisa, njll.

Inzuzo ye-HASL

1. Isikhathi eside sokulondoloza.

2. Ukumanzisa kahle iphedi nokumbozwa ngethusi.

3. Uhlobo olusetshenziswa kakhulu lomthofu (oluhambisana ne-RoHS).

4. Ubuchwepheshe obuvuthiwe, izindleko eziphansi.

5. Ifanele kakhulu ukuhlolwa okubonakalayo nokuhlolwa kukagesi.

Ubuthakathaka be-HASL

1. Ayifanele ukuxhunywa ngocingo.

2. Ngenxa ye-meniscus yemvelo ye-solder encibilikisiwe, i-flatness impofu.

3. Akusebenzi kumaswishi e-capacitive touch.

4. Kumaphaneli amancane kakhulu, i-HASL ingase ingafaneleki. Ukushisa okuphezulu kokugeza kungase kubangele ibhodi lesifunda ukuba ligoqe.

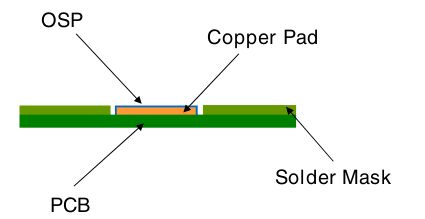

2. UMnyango Wezomlilo Wokuzithandela

I-OSP isifinyezo se-Organic Solderability Preservative, eyaziwa nangokuthi i-solder ngayinye. Ngamafuphi, i-OSP iwukuthi kufanele ifuthwe ebusweni be-solder pads yethusi ukunikeza ifilimu evikelayo eyenziwe ngamakhemikhali e-organic. Le filimu kufanele ibe nezakhiwo ezinjengokumelana ne-oxidation, ukumelana nokushaqeka okushisayo nokumelana nomswakama ukuze kuvikelwe indawo yethusi ekugqwaleni (i-oxidation noma i-vulcanization, njll.) ezindaweni ezivamile. Kodwa-ke, ekufakweni kwe-solder yokushisa okuphezulu okulandelayo, le filimu evikelayo kufanele isuswe kalula yi-flux ngokushesha, ukuze indawo yethusi ehlanzekile evezwe ikwazi ukuhlangana ngokushesha ne-solder encibilikisiwe ukuze yakhe i-solder eqinile ngesikhathi esifushane kakhulu. Ngamanye amazwi, indima ye-OSP iwukuba ivimbe phakathi kwethusi nomoya.

Inzuzo ye-OSP

1. Ilula futhi iyathengeka; Isiphetho esingaphezulu siwukugcotshwa kwesifutho kuphela.

2. Ingaphezulu le-solder pad libushelelezi kakhulu, linokucabana okuqhathaniswa ne-ENIG.

3. Ukuhola mahhala (okuhambisana namazinga e-RoHS) futhi ayihambisani nemvelo.

4. Isebenza kabusha.

Ubuthakathaka be-OSP

1. Ukungemanzi kahle.

2. Imvelo ecacile nencane yefilimu isho ukuthi kunzima ukukala ikhwalithi ngokuhlola okubonakalayo kanye nokwenza ukuhlola ku-inthanethi.

3. Impilo yesevisi emfushane, izidingo eziphezulu zokugcina nokuphatha.

4. Ukuvikelwa okungekuhle kokufakwa emigodini.

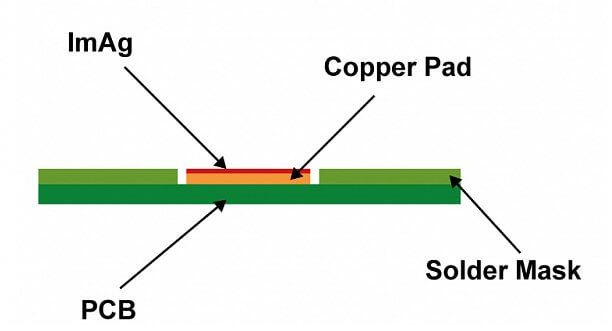

Isiliva Sokucwiliswa

Isiliva linezinto zamakhemikhali ezizinzile. I-PCB ecutshungulwa ubuchwepheshe bokucwiliswa kwesiliva isenganikeza ukusebenza okuhle kukagesi ngisho nalapho ibekwe endaweni eshisa kakhulu, enomswakama nengcolile, kanye nokugcina i-solderability enhle ngisho noma ingase ilahlekelwe ukucwebezela kwayo. I-Immersion Silver iyindlela yokusabela lapho ungqimba lwesiliva oluhlanzekile lufakwa khona ethusi. Kwesinye isikhathi, isiliva lokucwiliswa lihlanganiswa nezingubo ze-OSP ukuvikela isiliva ukuthi lingasabeli nama-sulfide endaweni.

Inzuzo Yesiliva Yokucwiliswa

1. I-solderability ephezulu.

2. Ukubukeka kahle kwendawo.

3. Izindleko eziphansi nokuhola mahhala (okuhambisana nezindinganiso ze-RoHS).

4. Isebenza ku-Al wire bonding.

Ubuthakathaka bokucwiliswa kwesiliva

1. Izimfuneko zokugcina eziphezulu futhi kulula ukungcoliswa.

2. Isikhathi esifushane sokuhlanganisa iwindi ngemuva kokukhipha emaphaketheni.

3. Kunzima ukwenza ukuhlolwa kukagesi.

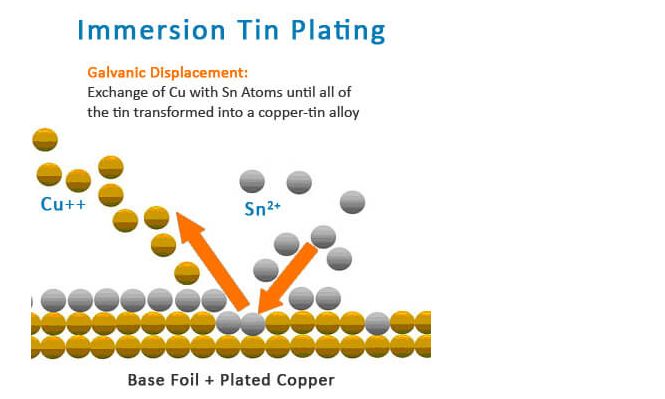

I-Tin yokucwiliswa

Njengoba yonke i-solder isekelwe ku-tin, ungqimba lwethini lungafanisa nanoma yiluphi uhlobo lwe-solder. Ngemva kokwengeza izithasiselo eziphilayo kusixazululo sokucwiliswa kwe-tin, isakhiwo sesendlalelo se-tin sibonisa isakhiwo se-granular, sinqoba izinkinga ezibangelwa amadevu e-tin nokufuduka kwe-tin, kuyilapho futhi kunokusimama okuhle kokushisa nokuqina.

Inqubo ye-Immersion Tin ingakha izinhlanganisela zethusi eziyisicaba ze-intermetallic ukwenza ithini lokucwiliswa libe nokudaleka okuhle ngaphandle kwanoma yikuphi ukucaba noma izinkinga zokusabalalisa kwenhlanganisela ye-intermetallic.

Inzuzo ye-Immersion Tin

1. Isebenza emigqeni yokukhiqiza evundlile.

2. Isebenza ekucutshungulweni kwezintambo ezicolekileyo kanye nokusoda okungenayo umthofu, ikakhulukazi okusebenza enqubweni yokuhlanganisa.

3. Ukucaba kuhle kakhulu, kusebenza ku-SMT.

Ubuthakathaka be-Immersion Tin

1. Imfuneko yesitoreji esiphezulu, ingase ibangele ukuthi izigxivizo zeminwe zishintshe umbala.

2. Amadevu kathayela angabangela amasekhethi amafushane kanye nezinkinga zamalunga e-solder, ngaleyo ndlela anciphise isikhathi sokuphila.

3. Kunzima ukwenza ukuhlolwa kukagesi.

4. Inqubo ihilela ama-carcinogens.

VUMA

I-ENIG (Electroless Nickel Immersion Gold) iyimbongolo yokuqeda esetshenziswa kabanzi eyakhiwe ngezingqimba zensimbi ezi-2, lapho i-nickel ifakwa khona ngqo ethusi bese ama-athomu egolide agxivizwa ethusi ngokusabela kokugudluka. Ugqinsi longqimba lwangaphakathi lwe-nickel luvamise ukuba ngu-3-6um, futhi ugqinsi lwe-deposition yegolide yangaphandle ngokuvamile luyi-0.05-0.1um. I-nickel yakha ungqimba oluvimbela phakathi kwe-solder nethusi. Umsebenzi wegolide ukuvimbela i-nickel oxidation ngesikhathi sokugcinwa, ngaleyo ndlela kunwebe impilo yeshalofu, kodwa inqubo yokucwiliswa kwegolide ingaphinda ikhiqize ukushelela okuphezulu kwendawo.

Ukugeleza kokucubungula kwe-ENIG yilokhu: ukuhlanza-->i-etching-->catalyst-->chemical nickel plating-->gold deposition-->insalela yokuhlanza

Inzuzo ye-ENIG

1. Ifanele i-solder yamahhala (ihambisana ne-RoHS)

2. Ubushelelezi bobuso obuhle kakhulu.

3. Impilo yeshalofu ende nendawo ehlala isikhathi eside.

4. Ifanele i-Al wire bonding.

Ubuthakathaka be-ENIG

1. Kuyabiza ngenxa yokusebenzisa igolide.

2. Inqubo eyinkimbinkimbi, okunzima ukuyilawula.

3. Kulula ukukhiqiza into yephedi emnyama.

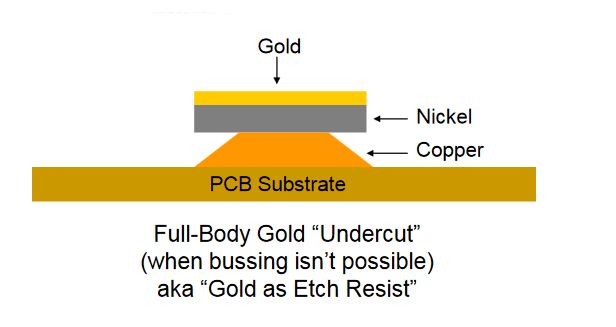

I-Electrolytic Nickel/Igolide(igolide eliqinile/igolide elithambile)

Electrolytic nickel gold ihlukaniswe “igolide eliqinile” kanye “negolide elithambile”. Igolide eliqinile linobumsulwa obuphansi futhi livame ukusetshenziswa eminwe yegolide (izixhumi zonqenqema ze-PCB), othintana nabo be-PCB noma ezinye izindawo ezingagugi. Ubukhulu begolide bungahluka kuye ngokwezidingo. Igolide elithambile linobumsulwa obuphakeme futhi livame ukusetshenziswa ekubopheni izintambo.

Inzuzo ye-Electrolytic Nickel/Gold

1. Impilo yeshalofu ende.

2. Ifanele ukushintshwa kothintana naye kanye nokubopha ngocingo.

3. Igolide eliqinile lifanele ukuhlolwa kukagesi.

4. I-lead free (ihambisana ne-RoHS)

Ubuthakathaka be-Electrolytic Nickel/Gold

1. Indawo ebiza kakhulu yokuqeda.

2. Iminwe yegolide ye-Electroplating idinga izintambo ezengeziwe.

3. Ukube igolide alikwazi ukutholakala kalula. Ngenxa yobukhulu begolide, izingqimba eziminyene kunzima kakhulu ukuzithengisa.

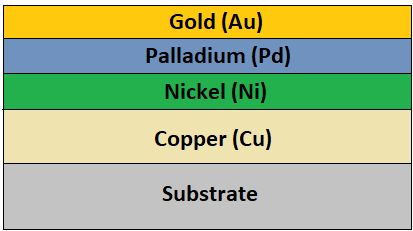

UTHISHANHLOKO

I-Electroless Nickel Electroless Palladium Immersion Gold noma i-ENEPIG iya ngokuya isetshenziselwa ukuphela kwe-PCB. Uma kuqhathaniswa ne-ENIG, i-ENEPIG yengeza ungqimba olwengeziwe lwe-palladium phakathi kwe-nickel negolide ukuze kuqhutshekwe nokuvikela ungqimba lwe-nickel ekugqwaleni nokuvimbela ukukhiqiza amaphedi amnyama akha kalula enqubweni yokuqeda indawo ye-ENIG. Ubukhulu be-nickel be-deposition bungaba ngu-3-6um, ubukhulu be-palladium bungaba ngu-0.1-0.5um kanye nogqinsi lwegolide ngu-0.02-0.1um. Nakuba ubukhulu begolide buncane kune-ENIG, i-ENEPIG ibiza kakhulu. Nokho, ukwehla kwakamuva kwezindleko ze-palladium kwenze intengo ye-ENEPIG yafinyeleleka kakhulu.

Inzuzo ye-ENEPIG

1. Inazo zonke izinzuzo ze-ENIG, akukho mkhuba wephedi elimnyama.

2. Ifaneleka kakhulu i-wire bonding kune-ENIG.

3. Ayikho ingozi yokugqwala.

4. Isikhathi eside sokulondoloza, sihola mahhala (ihambisana ne-RoHS)

Ubuthakathaka be-ENEPIG

1. Inqubo eyinkimbinkimbi, okunzima ukuyilawula.

2. Izindleko eziphezulu.

3. Kuyindlela entsha futhi engakavuthwa.