FPC

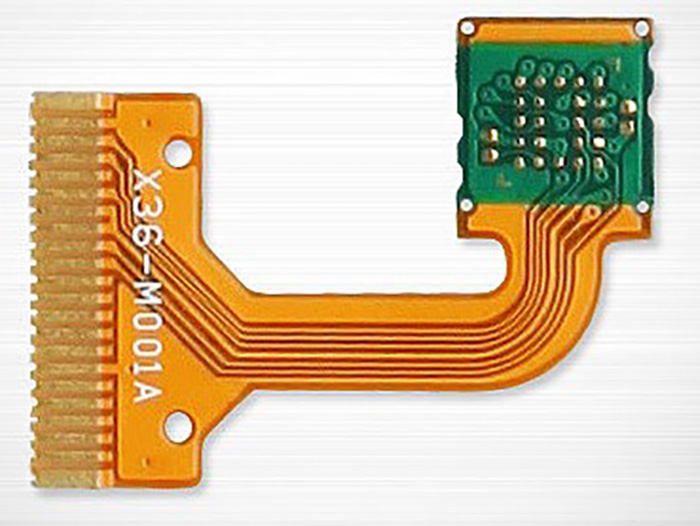

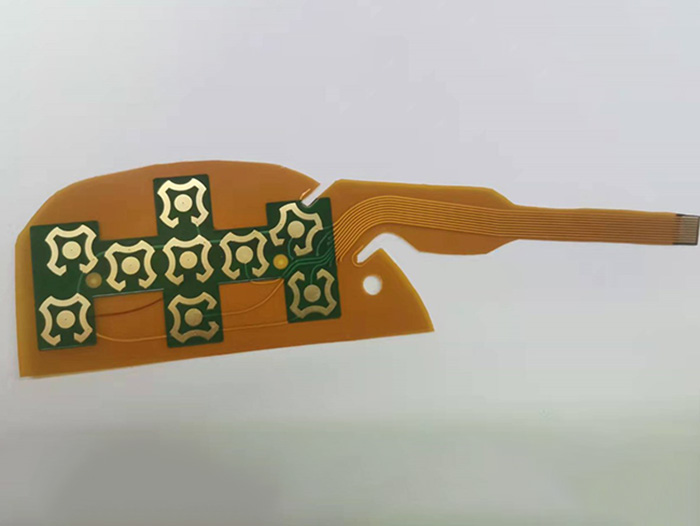

1.FPC—Flexible Printed Circuit, a highly reliable and flexible printed circuit made by etching onto copper foil using polyester film or polyimide as the substrate to form a circuit.

2.Product Characteristics: ① Small size and light weight : meeting the needs of high-density, miniaturization, lightweight, thinness and high reliability development directions; ② High flexibility : can move and expand freely in 3D space, achieving integrated component assembly and wire connection.

FPC application:

camera, video camera, CD-ROM, DVD, hard drive, laptop, telephone, mobile phone, printer, fax machine, TV, medical equipment, automotive electronics, aerospace and military products.

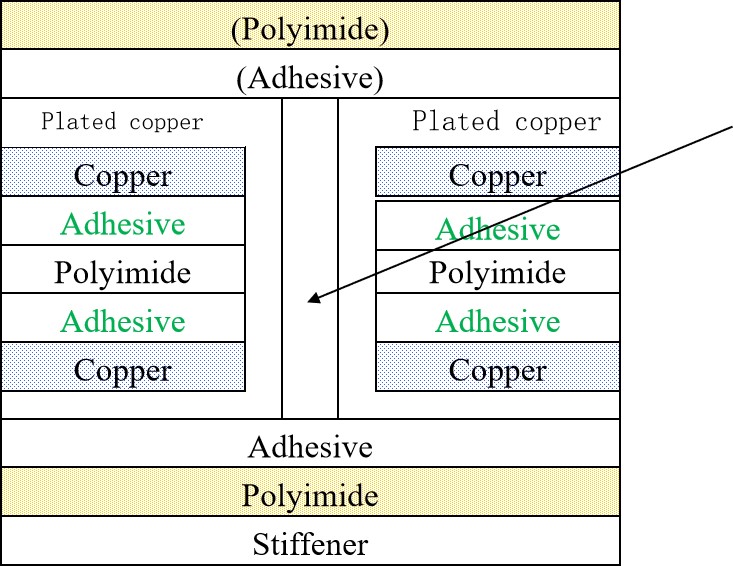

FPC double side flexible board

FPC classification

According to the number of conductive layers, it can be divided into single-sided board, double-sided board and multi-layer board

Single-sided board : conductor on one side only

Double-sided board : there’re 2 conductors on both sides, and to establish electrical connection between 2 conductors with through hole (via) as a bridge. A through hole is a small copper plated hole on the hole wall that can be connected to the circuits on both sides.

Multi-layer board : contains 3 or more layers of conductors, with more precise layout.

Except single-sided board, the number of layers of rigid board is generally even, such as 2, 4, 6, 8 layers, mainly because the odd layer stacking structure is asymmetric and prone to board warping. On the other hand, flexible PCB is different as there’s no problem of warping, so 3-layer, 5-layer, etc. are common.

FPC basic materials

Copper Foil - Classification

Copper foil is devided into Electro-Deposited copper(ED Copper) and Rolled Annealed copper(RA Copper)

| Comparison between | RA copper | ED copper |

| Cost | high | low |

| Flexibility | good | poor |

| Purity | 99.90% | 99.80% |

| Microscopic structure | sheet-like | columnar |

So the application of dynamic bending must use RA copper, such as the connection plate for folding/sliding phones and the expansion&contraction parts of digital cameras. In addition to its price advantage, ED copper is also more suitable for the production of micro circuits due to its colomnar structure.

3. Copper foil specification

1oz ≈ 35um

OZ is actually a unit of weight ,equal to 1/16 pound, approximately 28.35g.

In the circuit board industry, the thickness of 1oz copper laid flat within one wquare foot is defined as 1oz. So sometimes clients ask for 28.35g of copper, we should immediately realize that this is a requirement for 1oz of copper.

| Adhesive Substrate | Adhesiveless Substrate | |||

| PI | AD | CU | PI | CU |

| 0.5mil | 12um | 1/3OZ | 0.5mil | 1/3OZ |

| 13um | 0.5OZ | 0.5OZ | ||

| 1mil | 13um | 0.5OZ | 1mil | 1/3OZ |

| 20um | 1OZ | 0.5OZ | ||

| 1OZ | ||||

| 2mil | 20um | 0.5OZ | 2mil | 0.5OZ |

| 1OZ | ||||

| 0.8mil | 1/3OZ | |||

| 0.5OZ | ||||

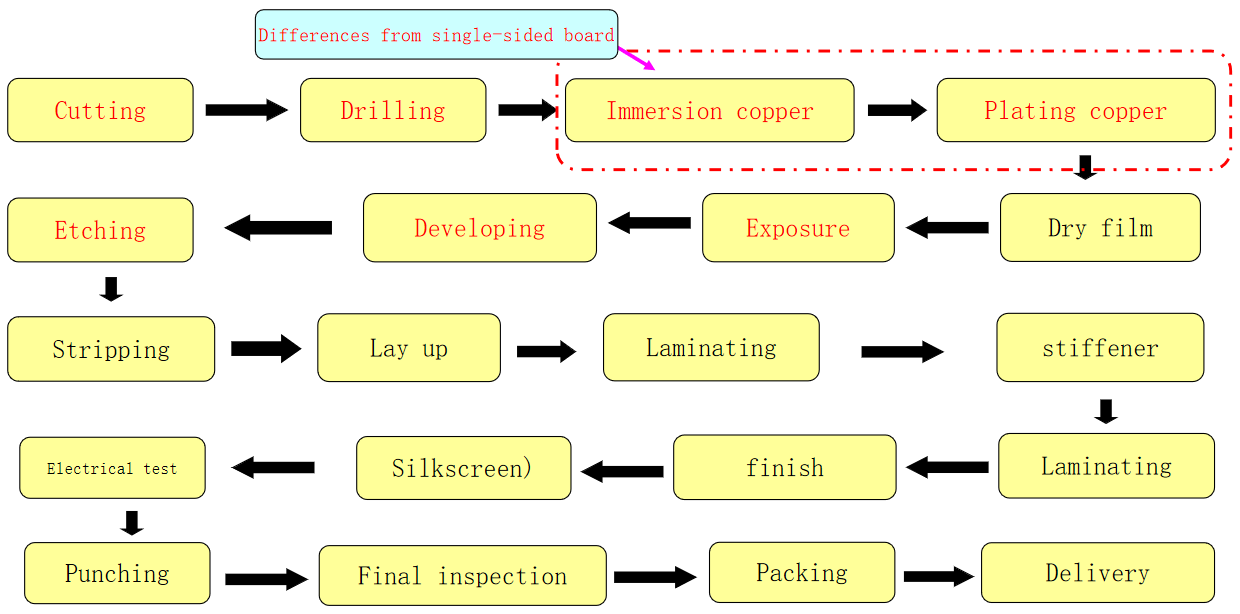

Double-sided Board Process

Solder Mask

Function of solder mask : ① surface insulation ② protect the circuit and prevent damage to the circuit ③ prevent conductive foreign objects from failing into the circuit and causing short circuits

There are 2 types of solder mask materials : ink and coverlay

The ink used for solder mask is generally photosensitive and called liquid photo imagealble, abbreviated as LPI. Generally available in green, black, white, red, yellow,blue, etc.

Coverlay, typically available in yellow (some called amber), black and white. Black has good blackout and white has high reflectivity, which can replace white ink for backlight flexible boards.

Comparison of Solder Mask

In the case of flexible board, both ink and coerlay can be used for soler mask. So what is the comparison between the advantages and disadvantages of the two? Please refer to the table below:

| Cost | Folding resistance | Alignment accuracy | Minimum solder bridge | Minimum window opening | Special shaped window | |

| Ink | Low | Poor | High | 0.15mm | 0.2mm | Yes |

| Coverlay | high | Good | low | 0.2mm | 0.5mm | Cannot open window in a “return” shape |

Surface finish

The function of surface finish is to prevent copper surface oxidation, provide welding or bonding layer.

There are usually several surface finish methods as below: specification for surface finish.

OSP: Organic solderability preservatives OSP:0.2-0.5um

Plating Ni/Au Plating Tin:4-20um

ENIG: Electroless Nickel Immersion Gold ENIG:0.05-0.1um

Plating Sn/Tin Plating gold:0.1-1um

Immersion Sn/Tin Immersion Tin:0.3-1.2um

Immersion Ag Immersion Ag:0.07-0.2um.

Cost comparison : Plating Ni/Au(ENIG) > Immersion Ag > Plating Sn/Tin (Immersion Sn/Tin) > OSP.

DST Double-Sided Tape

Unlike rigid board, flexible board do not have the same rigidity and machanical strength as rigid board, so it cannot be fixed well by screws or inserting card slots. Usually, it is necessary to fix it on the device with double-sided adhesive to prevent the FPC from shaking after assembly. In addition, double-sided adhesive can also be used to attach stiffener to FPC.

DST (Double-Sided Tape), also known as Pressure-Sensitive Adhesive (PSA), is a double-sided adhesive used for FPC.

Pressure Sensitive Adhesive can be divided into ordinary adhesive, high-temperature resistant adhesive, conductive adhesive and thermal conductive adhesive.

Ordinary adhesives include 3M467,3M468, conductive adhesives include 3M9703,3M9713

Thermal conductive adhesives include 3M8805,3M9882

High-temperature resistant adhesive refers to the adhesive that can withstand SMT high temperatures for a short period of time, used for boards that require SMT mounting. Commonly used adhesives include 3M9460,3M9077,3M9079,TESA8853,etc.

Types of Stiffeners

There are several types of stiffeners as below :

Stainless Steel (SS) : Some clients indicate SUS on their drawings, but in reality, this is steel stiffener. SUS is a commonly used type of steel sheets.

AL:Aluminum

FR4

Polyimide

Polyester

EMI

Electro-Magnetic Interference (EMI) is a common phenomenon, especially in high-frequency circuits, to ensure the integrity of the signal without distortion, electromagnetic shielding is necessary.The materials used for electromagnetic shielding of FPC mainly include silver ink and silver ink film.

Silver ink is a paste-like substance with metallic silver particles and resin. It can be printed on a FPC like silk screen ink in a rigid board, and then baked and solidified. To prevent oxidation of the silver in the air, a layer of ink or a protective film is usually printed on the silver ink for protection.

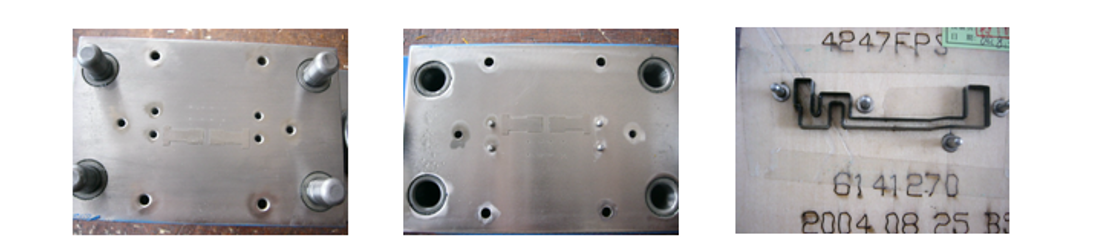

Mold

The commonly used molds are divided into knife mold and steel mold. The accuracy of knife mold is low, with a forming tolerance of about +/-0.3mm. The accuracy of steel mold is high, with ordinary steel mold about +/-0.1mm and precision steel mold up to +/-0.05mm. Of cause the price of steel molds is several or even tens of times that of knife molds.

Knife molds also known as soft tools, and steel molds also known as hard tools.

Electrical test

Use an electrical inspection instrument to fully power on the product to check for serious defects such as open, short, etc. in the product circuits. In the sampling stage, the quantity is relatively small, in order to save the cost of opening a testing frame, flying probe is used for testing. However, flying probe testing is relatively complex and takes a long time resulting in low efficiency. Therefore, testing is carried out using a testing frame (fixture, jig) during mass production.

The defects that can be found during electrical inspections include: item; open; short.

Attention should be paid to the occurrence of defects during electrical inspection : scratchs on the surface finish parts caused by electrical inspection probes

Final inspection

Conduct a comprehensive inspection of individual finished products according to inspection standards

There are several inspection methods according to the different requirements of the product as below :

① visual inspection

② microscopic inspection (minimum 10X)

Mainly inspect the appearance, including scratches, dents, wrinkles, oxidation, blistering, solder mask misalignment, drilling misalignment, circuit gaps, residual copper, foreign objects, etc.