01

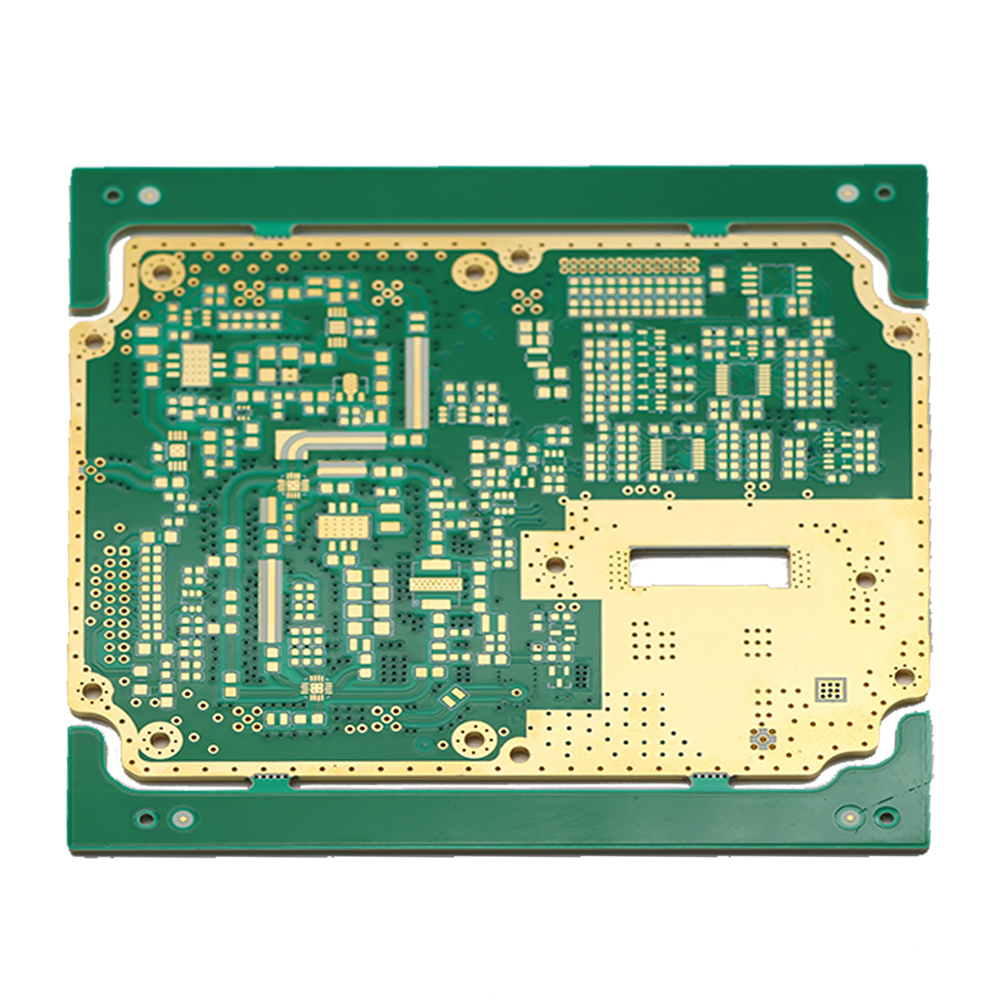

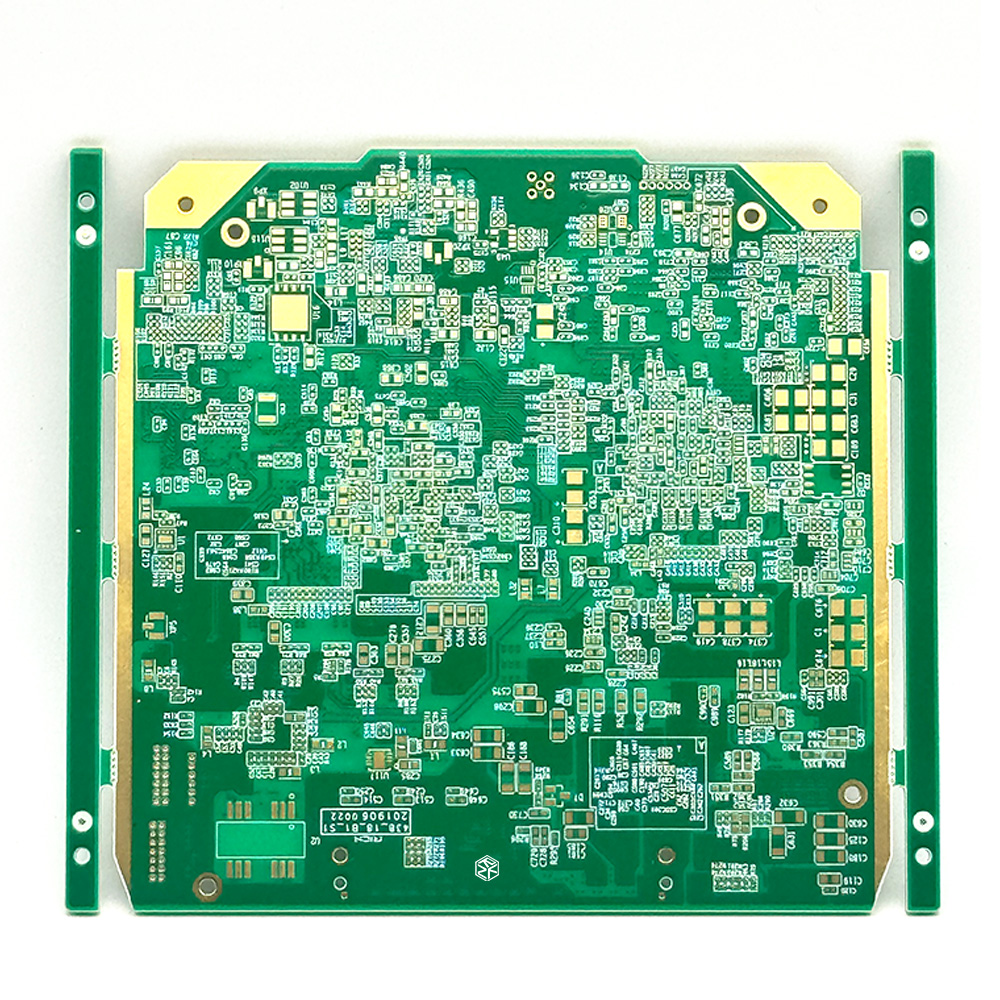

Multilayer PCB, kowane Layer HDI PCB

Babban Layer / kowane mai ƙirar HDI Layer

Ma'anar allo na HDI (High Density lnterconnection) allon kewayawa yana nufin Microvia PCB tare da buɗaɗɗen ƙasa da 6mm, Kushin Hole na ƙasa da 0.25mm, ƙimar lamba fiye da maki 130/sa'a murabba'i, ƙimar wayoyi na ƙari. fiye da maki 117/sa'a murabba'i, da faɗin layi / tazarar ƙasa da 3mi/3mi.

Rarraba HDI PCB: Layer 1, Layer 2, Layer 3 da kowane Layer HDI

Tsarin HDI Layer 1: 1+N+1 (latsa sau biyu, Laser sau ɗaya).

2 Layer HDI tsarin: 2+N+2 (latsa sau 3, Laser sau biyu).

3 Layer HDI Tsarin: 3+N+3 (latsa sau 4, Laser sau 3).

Duk wani Layer HDI yana nufin HDI wanda zai iya aiwatar da hakowar Laser daga ainihin PCB, a wata kalma, yana nufin cewa ana buƙatar hakowar Laser kafin latsawa.

Amfanin HDI PCB

1. Yana iya rage farashin PCB. Lokacin da yawan PCB ya ƙaru zuwa fiye da yadudduka 8, ana kera shi ta hanyar HDI kuma farashin sa zai yi ƙasa da tsarin matsi na gargajiya.

2. Ƙara yawan da'ira ta hanyar haɗa allunan kewayawa na al'ada da abubuwan haɗin gwiwa

3. Amfani ga amfani da ci-gaba fasahar marufi

4. Samun mafi kyawun aikin lantarki da daidaiton sigina

5. Kyakkyawan aminci

6. Zai iya inganta aikin thermal

7. Zai iya rage tsangwama ta mitar rediyo, tsangwama ta igiyoyin lantarki, da fitarwar lantarki (RFI/EMI/ESD)

8. Ƙara ƙirar ƙira

Babban bambance-bambance tsakanin HDI da PCB na yau da kullun

1. HDI yana da ƙarami ƙarami da nauyi mai nauyi

HDI PCB an yi shi da PCB mai gefe biyu na gargajiya a matsayin ainihin, ta hanyar ci gaba da haɓakawa da lamination. Irin wannan allon da'ira da aka yi ta ci gaba da shimfidawa ana kuma san shi da Build-up Multilayer (BUM). Idan aka kwatanta da allunan kewayawa na gargajiya, allunan da'ira na HDI suna da fa'idodi kamar su zama haske, sirara, gajere da ƙanana.

Haɗin wutar lantarki tsakanin allunan kewayawa na HDI ana samun su ta hanyar ramuka, binne/makafi ta hanyar haɗin gwiwa, waɗanda suka bambanta da tsarin allo na yau da kullun. Micro binne/makafi ta hanyar ana amfani dashi sosai a cikin HDI PCBs. HDI tana amfani da hakowa Laser kai tsaye, yayin da daidaitattun PCBs yawanci suna amfani da hakowa na inji, don haka adadin yadudduka da yanayin yanayin sau da yawa suna raguwa.

2. Tsarin kera na babban allon HDI

Babban haɓakar girma na HDI PCBs yana nunawa a cikin yawan ramuka, da'irori, pad ɗin solder da kauri mai tsaka-tsaki.

● Micro ta-ramuka: HDI PCBs ƙunshi makafi ramukan da sauran micro ta-rami kayayyaki, wanda aka yafi bayyana a cikin high bukatun na micro rami kafa fasaha tare da pore size kasa da 150um, kazalika da kudin, samar da yadda ya dace da kuma rami matsayi. daidaito iko. A cikin allunan kewayawa na gargajiya da yawa, akwai ramuka kawai kuma babu ƙananan ramukan binne/makafi

● Gyaran faɗin layi/tazara: galibi yana bayyana cikin ƙaƙƙarfan buƙatu don lahani na waya da rashin ƙarfi na waya. Faɗin layi na gaba ɗaya / tazarar bai wuce 76.2um ba

● Maɗaukakin kushin mai girma: Girman kayan haɗin gwal ɗin ya fi 50/cm2

● Thinning na dielectric kauri: Wannan ya fi bayyana a cikin Trend na interlayer dielectric kauri tasowa zuwa 80um da kuma kasa, da kuma da ake bukata domin kauri uniformity yana ƙara tsananta, musamman ga high-yawa PCBs da marufi substrates tare da halayyar impedance iko.

3. HDI PCB yana da mafi kyawun aikin lantarki

HDI ba zai iya rage ƙira na ƙarshe kawai ba, har ma ya dace da mafi girman matsayin aikin lantarki da inganci a lokaci guda.

Ƙara yawan haɗin haɗin haɗin gwiwa na HDI yana ba da damar haɓaka ƙarfin sigina da ingantaccen aminci. Bugu da kari, HDI PCBs suna da ingantacciyar haɓakawa a cikin raguwar tsangwama ta mitar rediyo, tsangwama na igiyar ruwa ta lantarki, fitarwar lantarki da tafiyar da zafi, da sauransu. zuwa lodi a cikin cikakken kewayon da ƙarfi mai ƙarfi na ɗan gajeren lokaci.

4. HDI PCBs suna da babban buƙatu don binne ta hanyar / toshe rami

Kamar yadda ake iya gani daga sama, duka dangane da girman allo da aikin lantarki, HDI ya fi PCBs na yau da kullun. Kowane tsabar kudin yana da bangarori biyu, da ɗayan ɓangaren HDI, a matsayin babban PCB, ƙirar masana'anta da wahalar aiwatarwa sun fi girma fiye da PCBs na yau da kullun, kuma akwai batutuwa da yawa don kula da su yayin samarwa, musamman ma binne ta hanyar. da toshe rami.

A halin yanzu, ainihin wurin zafi da wahala a cikin samarwa da masana'antu na HDI shine binne ta hanyar da toshe rami. Idan HDI da aka binne ta hanyar / toshe rami ba a yi kyau ba, za a sami manyan matsalolin inganci, gami da gefuna marasa daidaituwa, matsakaicin kauri mara daidaituwa da ramuka akan kushin solder.

● Madaidaicin saman allo da layukan da ba daidai ba na iya haifar da al'amuran rairayin bakin teku a wuraren da suka nutse, suna haifar da lahani kamar gibin layi da karyewa.

Har ila yau, ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun dielectric ba daidai ba ne, yana haifar da rashin kwanciyar hankali na sigina.

● Matsakaicin siyar da ba daidai ba yana haifar da rashin ingancin marufi na gaba, yana haifar da haɗin gwiwa da asarar abubuwan haɗin gwiwa da yawa.

Saboda haka, ba duk masana'antun PCB ba ne ke da iyawa da ƙarfin yin HDI da kyau, kuma RICH PCBA yana aiki tuƙuru don wannan sama da shekaru 20.

Mun sami sakamako mai kyau a cikin ƙira na musamman kamar madaidaicin madaidaici, mai girma, mai girma, babban sauri, babban TG, faranti mai ɗaukar hoto da RF PCB. Har ila yau, muna da wadataccen ƙwarewar samarwa a cikin matakai na musamman kamar matsananci-kauri, girman girman, jan ƙarfe mai kauri, matsa lamba mai tsayi mai tsayi, tubalan jan ƙarfe, rabin ramuka, ƙwanƙwasa baya, ƙwanƙwasa mai zurfi, yatsun zinare, allunan sarrafa madaidaicin madaidaici. , da dai sauransu.

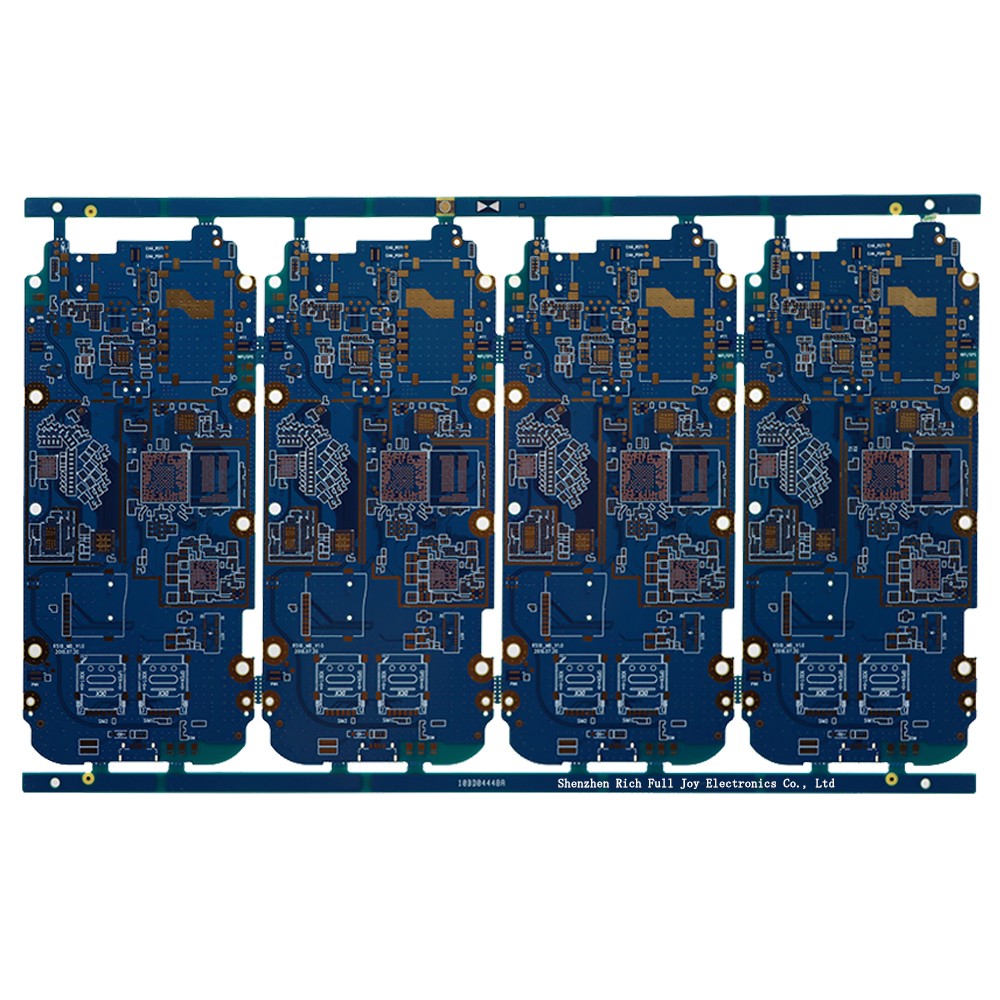

Aikace-aikacen (duba hoton da aka makala don cikakkun bayanai)

Ana amfani da HDI PCBs a fannoni daban-daban kamar wayoyin hannu, kyamarori na dijital, AI, masu ɗaukar hoto na IC, kayan aikin likitanci, sarrafa masana'antu, kwamfyutoci, na'urorin lantarki na mota, robots, drones, da sauransu.

Aikace-aikace

Ana amfani da HDI PCBs a fannoni daban-daban kamar wayoyin hannu, kyamarori na dijital, AI, masu ɗaukar hoto na IC, kayan aikin likitanci, sarrafa masana'antu, kwamfyutoci, na'urorin lantarki na mota, robots, drones, da sauransu.