PCB Circuit Design

PCB design

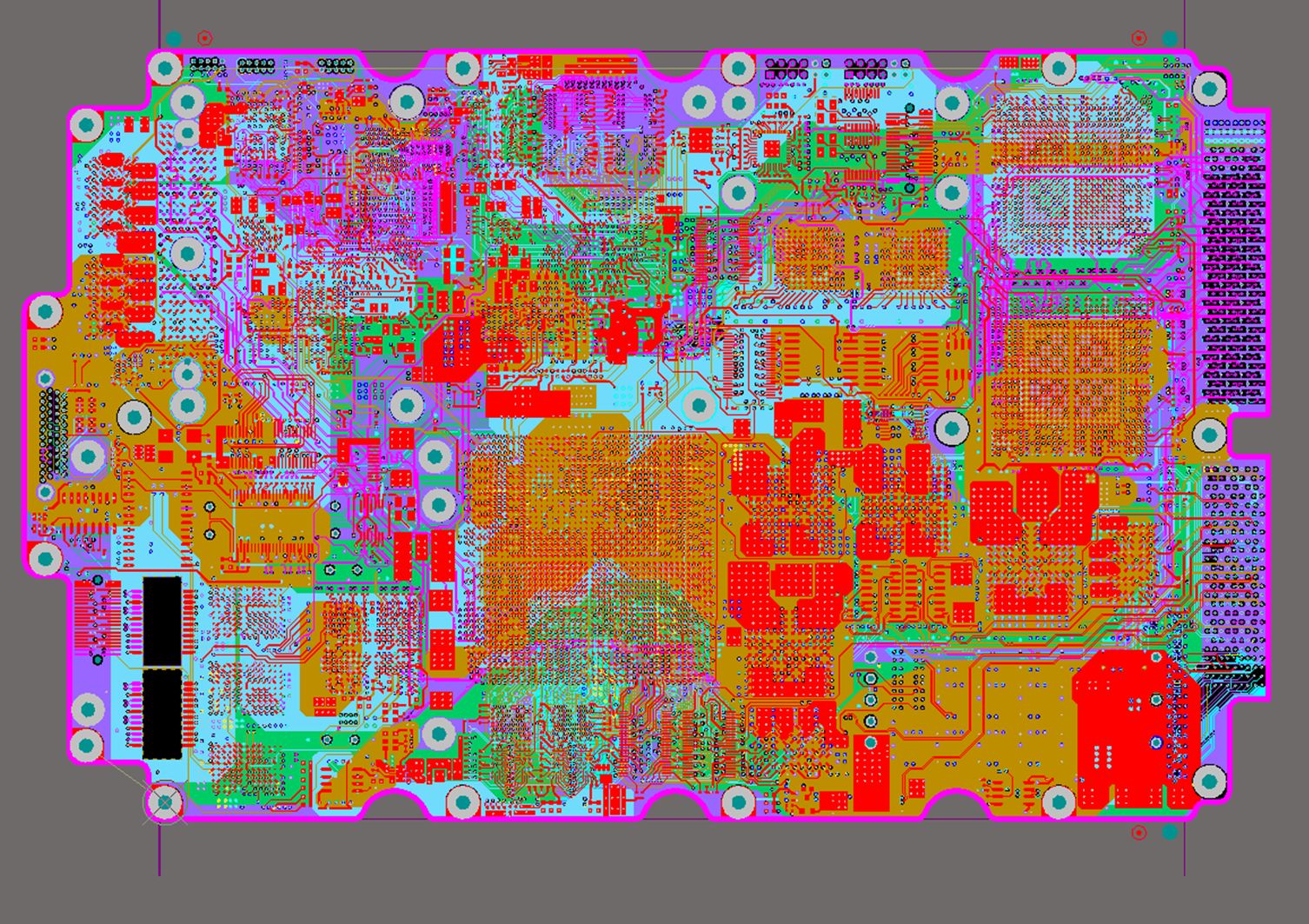

We’ve been committed to providing high-quality PCB design and one-stop electronic engineering for over a decade, winning customer trust with highly competitive prices and high-quality services. Regardless of the size of your project, we can meet the design requirements from product concept to production. Our comprehensive PCB design capabilities ensure understanding of your project’s technical requirements and DFM manufacturability design, without the need for multiple design iterations, which will become an important factor for customers to transition from product design to market.

We're capable of handling the following PCB design tasks:

High speed multi-layer digital PCB design

High frequency RF/microwave circuit board design

Low electrical level analog circuit board design

Ultra low electromagnetic interference design for magnetic resonance imaging

DDR2, DDR3, DDR4 memory design

Printed antenna design

Complete assembly diagram

Circuit test data generation

Selecting and placing data generation

Drilling, panelizing and V-Cut

Professional manufacturing documents

Automatic wiring for dense PCB design

We have rich experience in the following industries:

Remote communication

Industrial fuel transfer system

Industrial process control

Medical devices

Visual simulation system (virtual)

Aviation control equipment

Research on Scientific Multiprocessor System

Asynchronous transmission method hardware

High reliability computer hardware

Teleconference

Network hardware

RF transmission

Our PCB design complies with IPC 2200 standard series, the design scheme can be manufactured according to IPC 6011 and IPC 6012 standard, and assembled according to IPC-A-160 standard. According to your schedule, we’ll accurately and timely carry out relevant PCB design tasks, ensure mass production with high-quality design, and avoid rework.

Digital/high-speed and analog design capabilities include:

Circuit design and analysis

FPGA to ASIC conversion

Component analysis and evaluation

Compliance and Value Engineering

Pulse circuit

Analog circuit simulation

Embedded microprocessors and chipsets for Power PC, Intel x86, TI DSP, Mellanox, Broadcom, as well as various other chipsets used in server, telecom, industrial and commercial segments

Our mechanical engineering capabilities include:

Packaging, Shell and Industrial Design

Product/System Architecture

Detailed mechanical design

Stress Analysis (FEA) Impact/Vibration Simulation

Thermal simulation

Material and component selection

Solid modeling

PCB linkage DFM/DFA and cost reduction

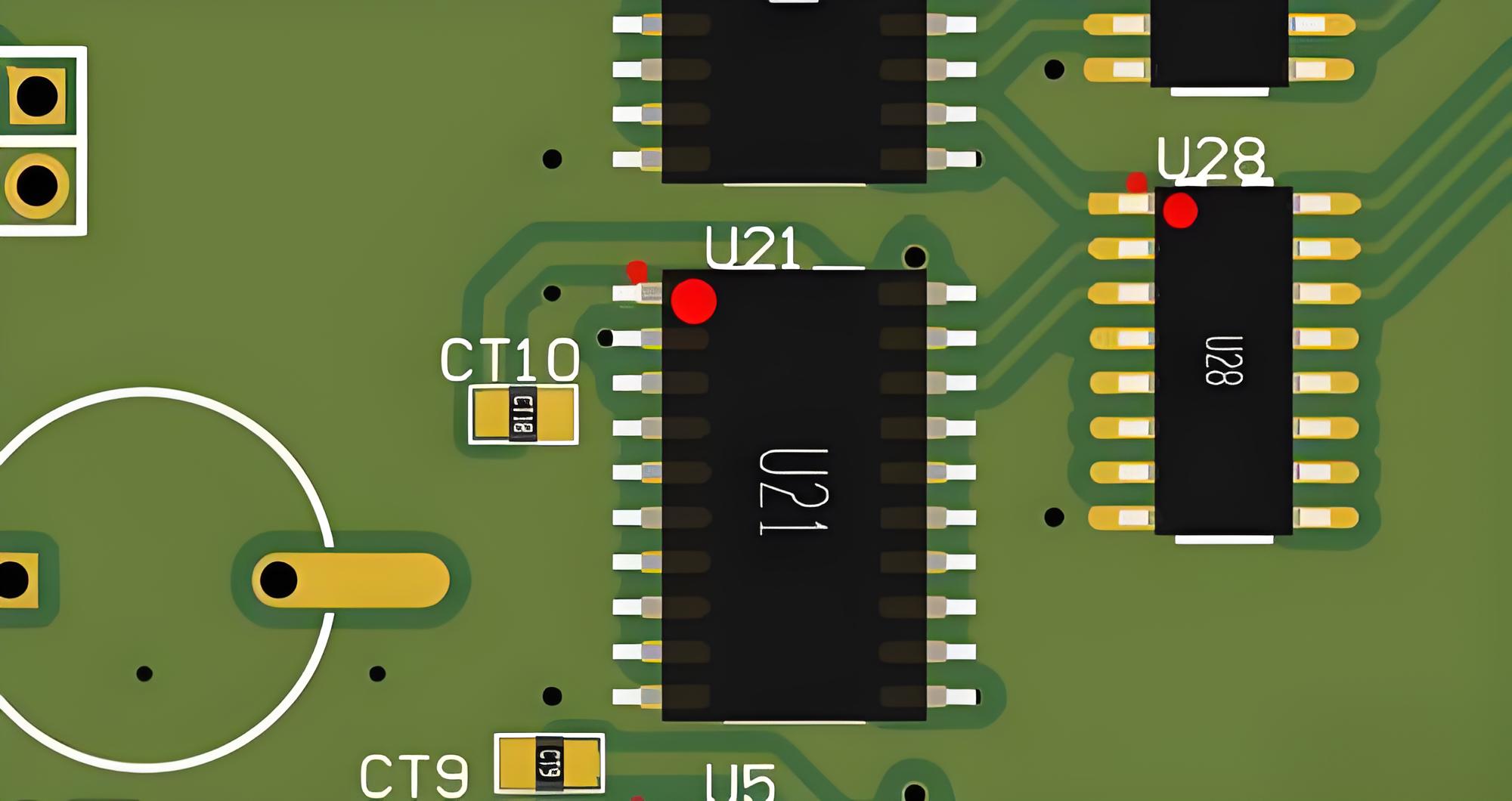

Free DFM Inspection

DFM inspection

We provide customers with free DFM manufacturability checks for PCBs, aiming to optimize product design and accuracy of manufacturing principles, processes and devices. This’ll greatly avoid product manufacturing risks and expose many defective projects for optimization and improvement before mass production or during the sampling stage.

PCB processing, DFM checklist

File version and last update time

Process: Lead/lead-free

Clear component tag and screen printing

BOM containing manufacturer’s brand, part number, description and item number

Confirm PCB production process: material, board thickness, copper thickness, number of layers, surface finish, character color and special process

Reasonable PCB pattern layers and panelizing style

Provide the correct SMT patch file

Comprehensive program recording and functional testing plan

Clear end product assembly manual and schematic diagram

Other special process requirements

Compatibility testing between BOM materials and PCB pads (customer engineers often fail to update the BOM in a timely manner during the design change process, resulting in purchasing incorrect materials)

Evaluate the process technology of PCBs, including but not limited to: processing sequence, steel mesh hole adjustment, furnace direction and carrier manufacturing, analysis of heat absorbing pads and surrounding components, protection of humility/thermal sensitive components, PCBA testing plan and detection rate, trial production quantity and trial production report, etc.

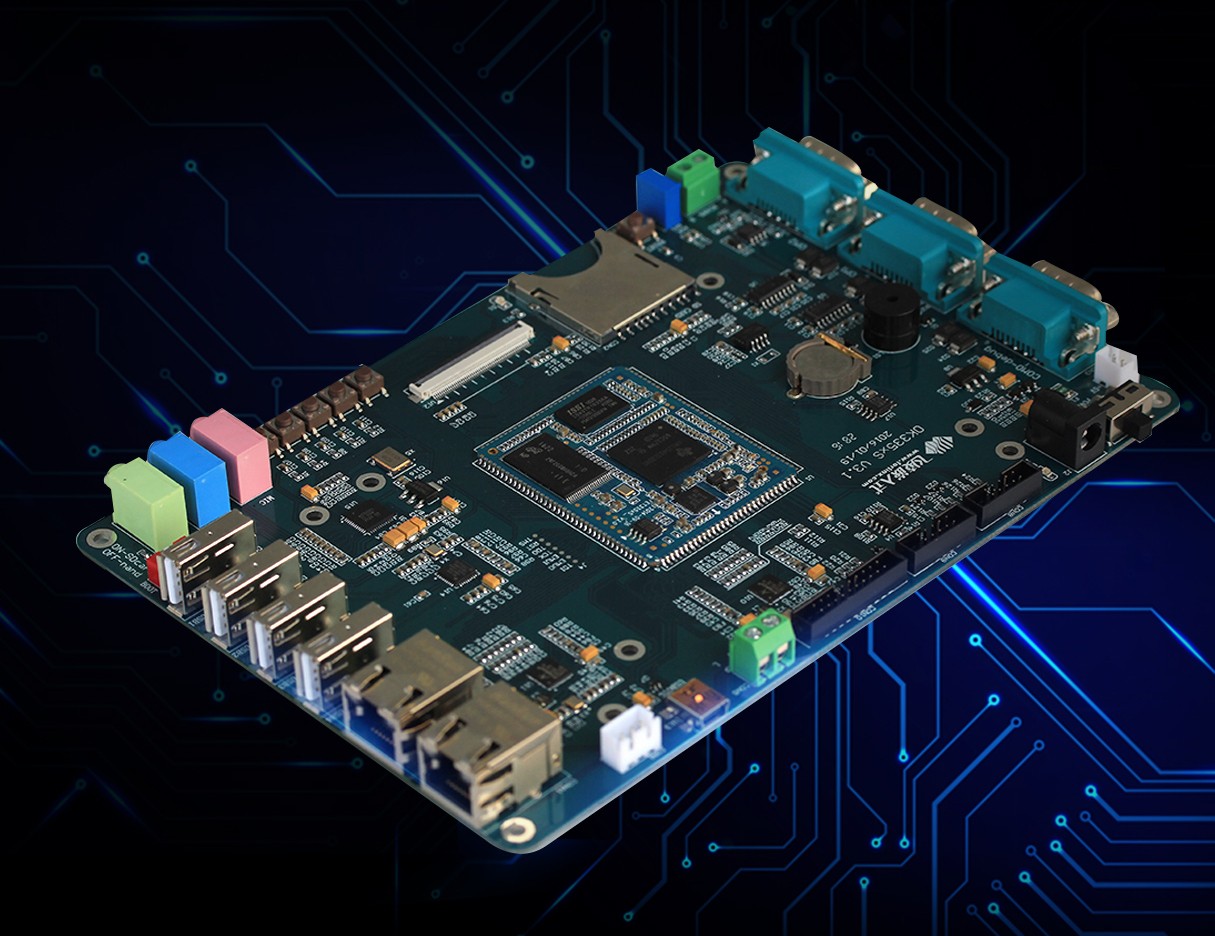

Embedded Development

Our embedded development outsourcing service can quickly address your technical concerns during the product development process. We have a team of 15-33 years of experienced engineers to undertake your embedded development projects, providing services in hardware, software, qualified testing and system integration.

We provide comprehensive design services for embedded development, including system architecture and design, electronic circuit board design and analysis, real-time software design, graphical user interface and tool development, PCB design, appearance design and packaging, etc. Customers will receive the documentation delivery after the project is completed.

The core competencies include the development of embedded systems for microprocessors and microcontrollers, and pre evaluation of the project in terms of EMI electromagnetic interference and environmental applications.

We’re proficient in the application of MCU microprocessors from brands such as Freescale, Infineon, Intel, Texas Instruments and Microprocessor, etc.

We also have extensive experience in control system, algorithm development and real-time embedded code development. Our software development capabilities include high-level and low-level languages, as well as research and development from modeling to automatic coding according to product needs.

Our embedded development experience includes:

Various analog and digital sensors

Core processor

Sensor and sensorless closed-loop control

Brushed and brushless AC and DC motor controller

Power

Multiple communication links

Battery and Energy Management

Integrated or distributed process control

Diagnosis/Prediction

System analysis

In order to control the traceablility of change requirements during embedded development, we have established a configuration management system to track hardware and software version levels and changes. Our embedded development involves lifecycle management from prototype to product design, providing customized applications for customers in industries such as industrial control, IoT, healthcare, aerospace, military, telecommunications, etc.

We understand the core technical and business issues of your system requirements and are able to build innovative, secure and reliable embedded systems.

Our goal is to create end-to-end embedded solutions that meet the needs of each customer and integrate them into their business processes, including embedded system architecture and design, real-time software design, document producing, prototyping and manufacturing, schematic design, BOM management and procurement and embedded C/C++ coding of microcontrollers.

Our expertise in embedded system development, validated processes and tools provide our customers with excellent quality, reliability and fast delivery speed.

We use open and proprietary operating systems to create software at all levels, from firmware to application software.

NPI Trial Production Report

We provide a fee NPI (New Product Introduction) trial production report, which records the production process, design and manufacturing defects, production optimization suggestions, quality optimizaition plans and other contents of sampling and small batch orders. The purpose is to guide customers in optimizing design, improving product manufacturability and product lifecycle.