PCB Surface Finish

| Surface Finish | Typical Value | Supplier |

| OSP | 0.3~0.55um, 0.25~0.35um | Enthone |

| Shikoku chemical | ||

| ENIG | Au : 0.03~0.12um, Ni : 2.5~5um | ATO tech/Chuang Zhi |

| Selective ENIG | Au : 0.03~0.12um, Ni : 2.5~5um | ATO tech/Chuang Zhi |

| ENEPIG | Au : 0.05~0.125um, Pd : 0.05~0.3um, | Chuang Zhi |

| Ni : 3~10um | ||

| Hard Gold | Au : 0.127~1.5um , Ni : min 2.5um | Platec/EEJA |

| Soft Gold | Au : 0.127~0.5um , Ni : min 2.5um | EEJA |

| Immersion Tin | Min : 1um | Enthone / ATO tech |

| Immersion Silver | 0.127~0.45um | Macdermid |

| Lead free HASL | 1~25um | Nihon Superior |

Due to the fact that copper exists in the form of oxides in the air, it seriously affects the solderability and electrical performance of PCBs. Therefore, it is necessary to carry out surface finish of PCBs. If the surface of PCBs is not finished, it is easy to cause virtual soldering problems, and in severe cases, solder pads and components cannot be soldered. PCB surface finish refers to the process of artificially forming a surface layer on a PCB. The purpose of PCB finish is to ensure that the PCB has good solderability or electric performance. There are many types of surface finish for PCBs.

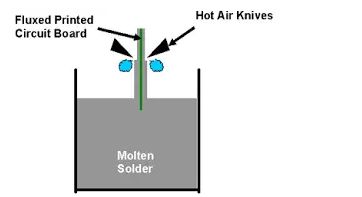

Hot Air Solder Leveling (HASL)

It is a process of applying molten tin lead solder on the surface of a PCB, flattening (blowing) it with heated compressed air and forming a layer of coating that is both resistant to copper oxidation and provides good solderability. During this process, it is necessary to master the following important parameters : soldering temperature, hot air knife temperature, hot air knife pressure, immersion time, lifting speed, etc.

Advantage of HASL

1. Longer storage time.

2. Good pad wetting and copper coverage.

3. Widely used lead free (RoHS compliant) type.

4. Mature technology, low cost.

5. Very suitable for visual inspection and electric testing.

Weakness of HASL

1. Not suitable for wire bonding.

2. Due to the natural meniscus of the molten solder, the flatness is poor.

3. Not applicable to capacitive touch switches.

4. For particularly thin panels, HASL may not be suitable. The high temperature of the bath may cause the circuit board to warp.

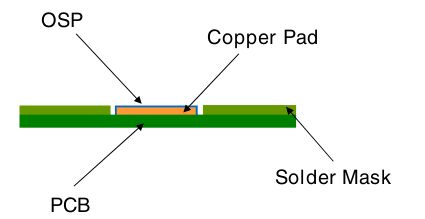

2. OSP

OSP is the abbreviation for Organic Solderability Preservative, also known as per solder. In short, OSP is that to be sprayed on the surface of copper solder pads to provide a protective film made of organic chemicals. This film must have properties such as oxidation resistance, thermal shock resistance and moisture resistance to protect the copper surface from rusting (oxidation or vulcanization, etc.) in normal environments. However, in the subsequent high-temperature soldering, this protective film must be easily removed by the flux quickly, so that the exposed clean copper surface can immediately bond with the melted solder to form a strong solder joint in a very short time. In other words, the role of OSP is to act as a barrier between copper and air.

Advantage of OSP

1. Simple and affordable; The surface finish is only spray coating.

2. The surface of the solder pad is very smooth, with a flatness comparable to ENIG.

3. Lead free (compliant with RoHS standards)and environmentally friendly.

4. Reworkable.

Weakness of OSP

1. Poor wettability.

2. The clear and thin nature of the film means that it is difficult to measure quality through visual inspection and conduct online testing.

3. Short service life, high requirements for storage and handling.

4. Poor protection for plated through holes.

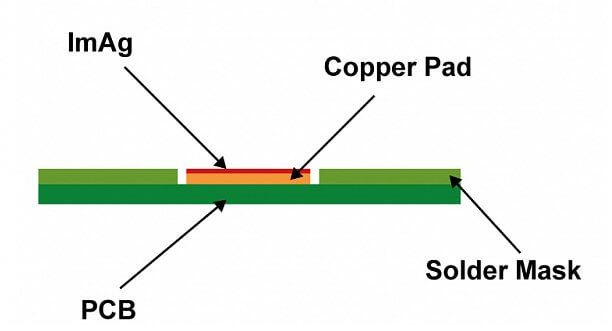

Immersion Silver

Silver has stable chemical properties. The PCB processed by silver immersion technology can still provide good electrical performance even when exposed to high temperature, humid and polluted environments, as well as maintain good solderability even if it may lose its luster. Immersion Silver is a displacement reaction where a layer of pure silver is directly deposited on copper. Sometimes, immersion silver is combined with OSP coatings to prevent silver from reacting with sulfides in the environment.

Advantage of Immersion Silver

1. High solderability.

2. Good surface flatness.

3. Low cost and lead free (compliant with RoHS standards).

4. Applicable to Al wire bonding.

Weakness of Immersion Silver

1. High storage requirements and easy to be polluted.

2. Short assembly window time after taking out from the packaging.

3. Difficult to conduct electrical testing.

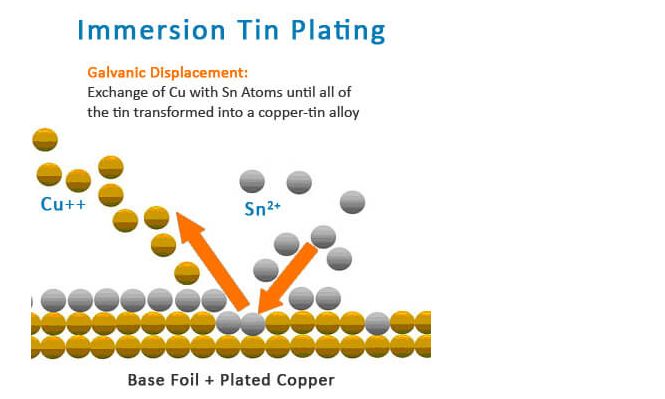

Immersion Tin

Since all solder is tin based, the tin layer can match any type of solder. After adding organic additives to the tin immersion solution, the tin layer structure presents a granular structure, overcoming the problems caused by tin whiskers and tin migration, while also having good thermal stability and solderability.

The Immersion Tin process can form flat copper tin intermetallic compounds to make immersion tin have good solderability without any flatness or intermetallic compound diffusion issues.

Advantage of Immersion Tin

1. Applicable to horizontal production lines.

2. Applicable to fine wire processing and lead-free soldering, especially applicable to crimping process.

3. The flatness is very good, applicable to SMT.

Weakness of Immersion Tin

1. High storage requirement, may cause fingerprints to change color.

2. Tin whiskers may cause short circuits and solder joint problems, thereby shorting the shelf life.

3. Difficult to conduct electrical testing.

4. The process involves carcinogens.

ENIG

ENIG (Electroless Nickel Immersion Gold) is a widely used surface finish coating composed of 2 metal layers, where nickel is directly deposited on copper and then gold atoms are plated onto copper through displacement reactions. The thickness of nickel inner layer is generally 3-6um, and the deposition thickness of the gold outer layer is generally 0.05-0.1um. The nickel forms a barrier layer between solder and copper. The function of gold is to prevent nickel oxidation during storage, thereby extending the shelf life, but the immersion gold process can also produce excellent surface flatness.

The processing flow of ENIG is : cleaning-->etching-->catalyst-->chemical nickel plating-->gold deposition-->cleaning residue

Advantage of ENIG

1. Suitable for lead free (RoHS compliant) soldering.

2. Excellent surface smoothness.

3. Long shelf life and durable surface.

4. Suitable for Al wire bonding.

Weakness of ENIG

1. Expensive because of using gold.

2. Complex process, difficult to control.

3. Easy to generate black pad phenomenon.

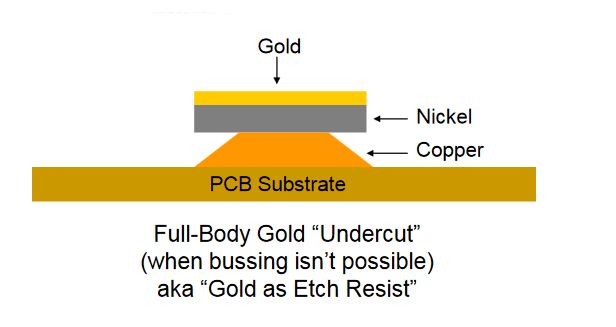

Electrolytic Nickel/Gold(hard gold/soft gold)

Electrolytic nickel gold is divided into “hard gold” and “soft gold”. Hard gold has a low purity and is commonly used in gold fingers (PCB edge connectors), PCB contacts or other wear-resistant areas. The thickness of gold may vary according to requirements. Soft gold has a higher purity and is commonly used in wire bonding.

Advantage of Electrolytic Nickel/Gold

1. Longer shelf life.

2. Suitable for contact switch and wire bonding.

3. Hard gold is suitable for electric testing.

4. Lead free (RoHS compliant)

Weakness of Electrolytic Nickel/Gold

1. Most expensive surface finish.

2. Electroplating gold fingers require additional conductive wires.

3. Had gold has poor solderability. Due to the gold thickness, thicker layers are more difficult to solder.

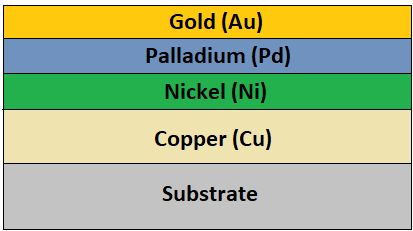

ENEPIG

Electroless Nickel Electroless Palladium Immersion Gold or ENEPIG is increasingly being used for PCB surface finish. Compared to ENIG, ENEPIG adds an extra layer of palladium between nickel and gold to further protect the nickel layer from corrosion and prevent generating black pads which are easily formed in ENIG surface finish process. The deposition thickness of nickel is about 3-6um, the thickness of palladium is about 0.1-0.5um and the thickness of gold is 0.02-0.1um. Although the thickness of gold is smaller than ENIG, the ENEPIG is more expensive. However, the recent decline in palladium costs has made ENEPIG’s price more affordable.

Advantage of ENEPIG

1. Has all advantages of ENIG, no black pad phenomenon.

2. More suitable for wire bonding than ENIG.

3. No risk of corrosion.

4. Long storage time, lead free (RoHS compliant)

Weakness of ENEPIG

1. Complex process, difficult to control.

2. High cost.

3. It’s a relatively new method and not yet mature.