Rigid-Flex Board

More Efficient Advanced Technology & Perfect Solution.

Advantages of Rigid-Flex Board

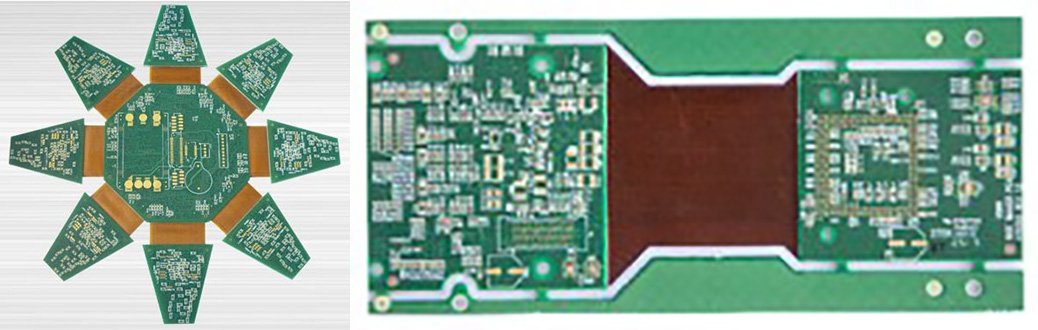

Nowadays, design is increasingly pursuing miniaturization, low cost and high speed of products, especially in the mobile device market , which usually involves high-density electronic circuits. Using Rigid-Flex Boards will be an excellent choice for the peripheral devices connected through IO. Seven major advantages brought by the design requirements of integrating flexible board materials and rigid board materials in the manufacturing process, combining the 2 substrate materials with prepreg, and then achieving interlayer electrical connection of conductors through through-holes or blind/buried vias are as below:

3D assembly to reduce circuits

Better connection reliability

Reduce the number of components and parts

Better impedance consistency

Can design highly complex stacking structure

Implement a more streamlined appearance design

Reduce size

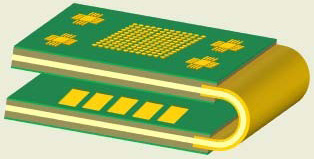

A rigid-flex is a board that combines rigidity and flexibility, processing both the rigidity of rigid board and flexibility of flexible board.

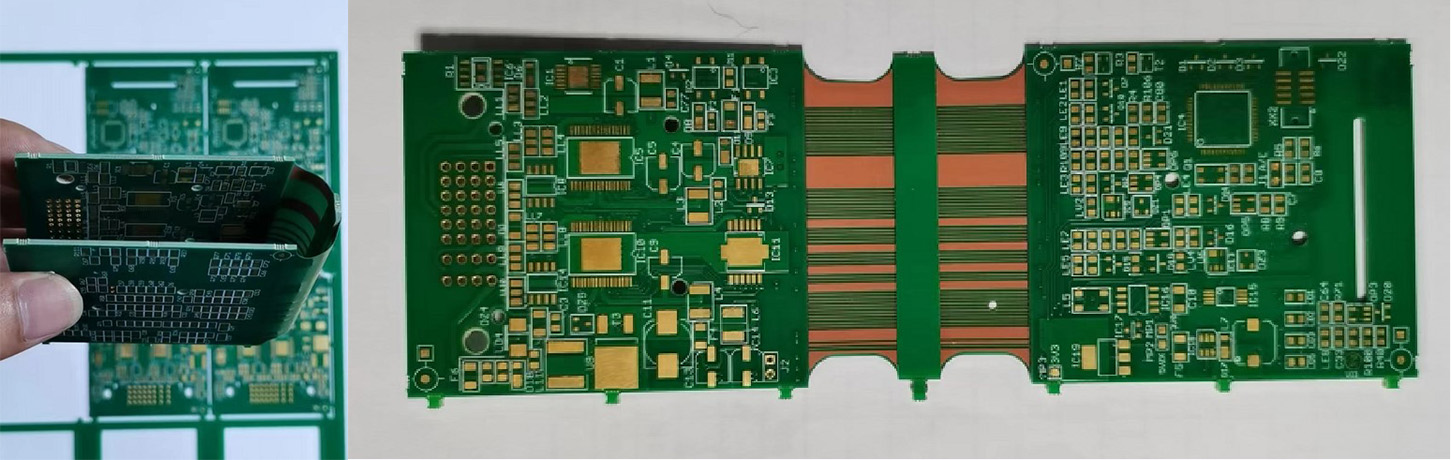

Semi FPC

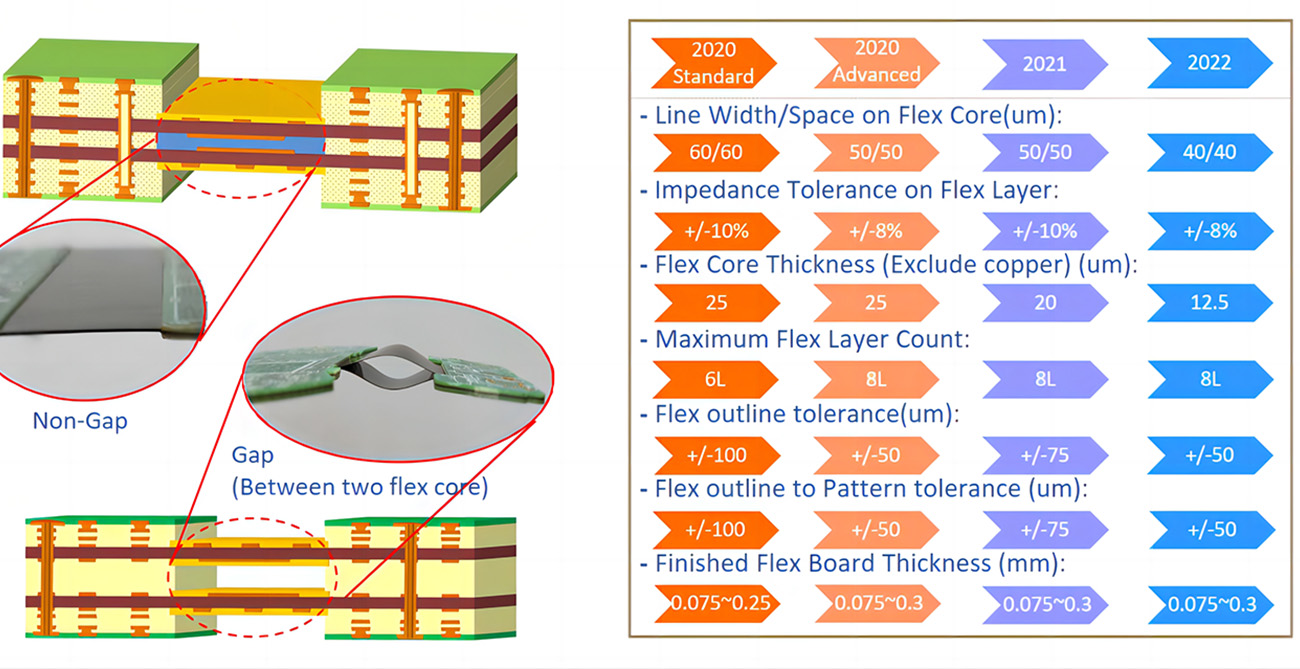

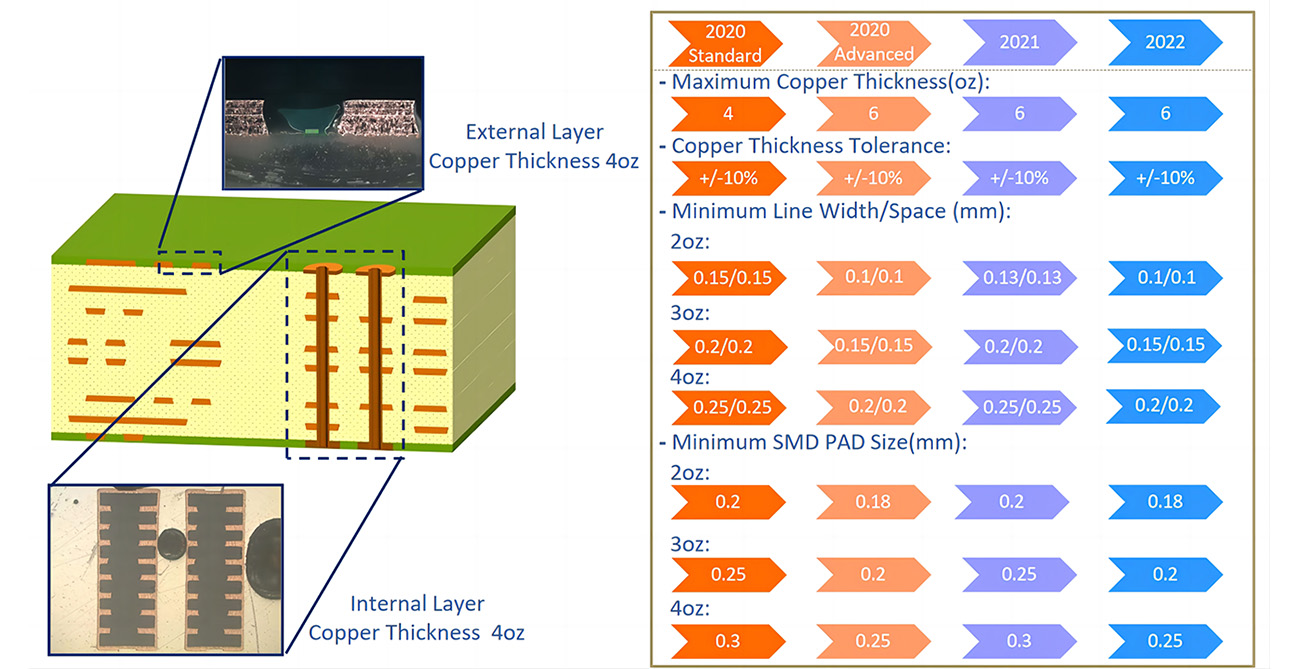

Capability Roadmap

| Item | Flex ‐ Rigid | Regal | Semi‐Flex |

| Figure |  |

|

|

| Flexible Material | Polyimide | FR4 + Coverlay(Polyimide) | FR4 |

| Flexible thickness | 0.025~0.1mm(Exclude copper) | 0.05~0.1mm (Exclude copper) | Remained Thickness: 0.25+/‐0.05mm(Dedicated Material: EM825(I)) |

| Bending angle | Max 180° | Max 180° | Max 180°(Flex layer≤2) Max 90°(Flex layer>2) |

| Flexural Endurance;IPC‐TM‐650,Method 2.4.3. | <1000 cycle | < 25 cycle | NA |

| Bending Test; 1) Mandrel diam:6.25mm | <10K cycle(Bending Angle:180°) | <500 cycle(Bending Angle:180°) | <10 cycle(Bending Angle:180°) |

| Application | Flex to install & Dynamic(Single side) | Flex to install | Flex to install |

| Surface Finish | Typical Value | Supplier | |

| OSP |  |

0.2~0.6um;0.2~0.35um | Enthone Shikoku chemical |

| ENIG |  |

Au:0.03~0.12um, Ni :2.5~5um | ATO tech/Chuang Zhi |

| Selective ENIG |  |

Au:0.03~0.12um, Ni :2.5~5um | ATO tech/Chuang Zhi |

| ENEPIG |  |

Au : 0.05~0.125um, Pd : 0.05~0.125um,Ni :5~10um | Chuang Zhi |

| Hard Gold |  |

Au:0.2~1.5um , Ni : min 2.5um | Platec |

| Soft Gold |  |

Au:0.15~0.5um , Ni : min 2.5um | EEJA |

| Immersion Tin |  |

Min: 1um | Enthone / ATO tech |

| Immersion Silver |  |

0.15~0.45um | Macdermid |

| HASL & Lead free HASL(OS) |  |

1~25um | Nihon Superior |

Au/Ni Type

● Gold plating can be divided into thin gold and thick gold according to thickness. Generally, gold below 4u”(0.41um) is called thin gold, while gold above 4u” is called thick gold. ENIG can only make thin gold, not thick gold. Only gold plating can make both thin and thick gold. The maximum thickness of thick gold on flexible board can be over 40u”. Thick gold is mainly used in working environments with bonding or wear resistance requirements.

● Gold plating can be divided into soft gold and hard gold by type. Soft gold is ordinary pure gold, while hard gold is cobalt containing gold. It’s precisely because cobalt is added that the hardness of the gold layer greatly increases exceeding 150HV to meet the wear resistance requirements.

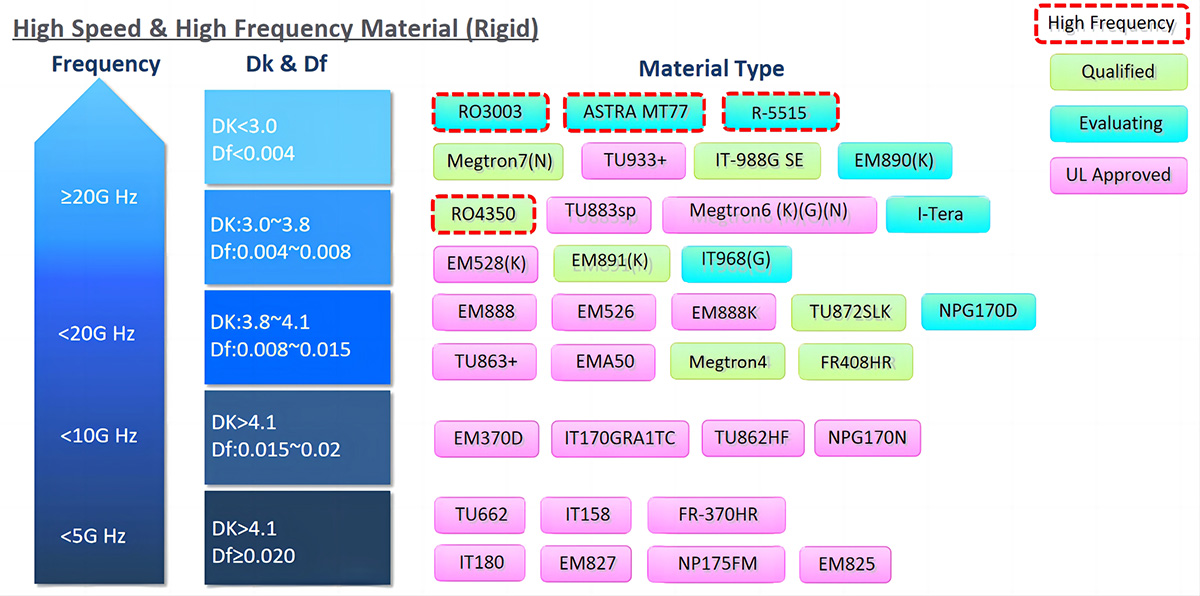

| Material Type | Properties | Supplier | |

| Rigid Material | Normal Loss | DK>4.2, DF>0.02 | NanYa / EMC / TUC / ITEQ / ShengYi / Isola / Doosan etc. |

| Middle Loss | DK>4.1, DF:0.015~0.02 | NanYa / EMC / TUC / ITEQ etc. | |

| Low Loss | DK:3.8~4.1, DF:0.008~0.015 | EMC / NanYa / TUC / Isola / Panasonic etc. | |

| Very Low Loss | DK:3.0~3.8, DF:0.004~0.008 | EMC / Panasonic / Rogers / TUC / Isola / ITEQ / NanYa etc. | |

| Ultra Low Loss | DK<3.0, DF<0.004 | Rogers / TUC / ITEQ / Panasonic / Isola etc. | |

| BT | Color:White / Black | MGC / Hitachi / NanYa / ShengYi etc. | |

| Copper Foil | Standard | Roughness(RZ)=6.34um | NanYa, KB, LCY |

| RTF | Roughness(RZ)=3.08um | NanYa, KB, LCY | |

| VLP | Roughness(RZ)=2.11um | MITSUI, Circuit Foil | |

| HVLP | Roughness(RZ)=1.74um | MITSUI, Circuit Foil | |

| Material Type | Normal DK/DF | Low DK/DF | |||

| Properties | Supplier | Properties | Supplier | ||

| Flex Material | FCCL(With ED & RA) | Normal Polyimide DK:3.0~3.3 DF:0.006~0.009 | Thinflex / Panasonic / Taiflex | Modified Polyimide DK:2.8~3.0 DF:0.003~0.007 | Thinflex / Taiflex |

| Coverlay(Black/Yellow) | Normal Adhesive DK:3.3~3.6 Df:0.01~0.018 | Taiflex / Dupont | Modified Adhesive DK:2.8~3.0 DF:0.003~0.006 | Taiflex / Arisawa | |

| Bond‐film(Thickness: 15/25/40 um) | Normal Epoxy DK:3.6~4.0 DF:0.06 | Taiflex / Dupont | Modified Epoxy DK:2.4~2.8 DF:0.003~0.005 | Taiflex / Arisawa | |

| S/M Ink | Solder mask;Color: Green / Blue / Black / White / Yellow / Red | Normal Epoxy DK:4.1 DF:0.031 | Taiyo / OTC / AMC | Modified Epoxy DK:3.2 DF:0.014 | Taiyo |

| Legend ink | Screen Color: Black / White / Yellow Inkjet Color: White | AMC | |||

| Other Materials | IMS | Insulated Metallic Substrates ( with Al or Cu ) | EMC / Ventec | ||

| High Thermal Conductive | 1.0 / 1.6 / 2.2 (W/M*K) | ShengYi / Ventec | |||

| EMI | Silver foil (SF‐PC6000‐U1 / SF‐PC8600‐C) | Tatsuta | |||

High Speed & High Frequency Material (Flexible)

| DK | Df | Material Type | |

| FCCL (Polyimide) | 3.0~3.3 | 0.006~0.009 | Panasonic R‐775 series;Thinflex A series;Thinflex W series;Taiflex 2up series |

| FCCL (Polyimide) | 2.8~3.0 | 0.003~0.007 | Thinflex LK series;Taiflex 2FPK series |

| FCCL (LCP) | 2.8~3.0 | 0.002 | Thinflex LC series;Panasonic R‐705T se;Taiflex 2CPK series |

| Coverlay | 3.3~3.6 | 0.01~0.018 | Dupont FR series; Taiflex FGA series; Taiflex FHB series;Taiflex FHK series |

| Coverlay | 2.8~3.0 | 0.003~0.006 | Arisawa C23 series;Taiflex FXU series |

| Bonding Sheet | 3.6~4.0 | 0.06 | Taiflex BT series;Dupont FR series |

| Bonding Sheet | 2.4~2.8 | 0.003~0.005 | Arisawa A23F series;Taiflex BHF series |

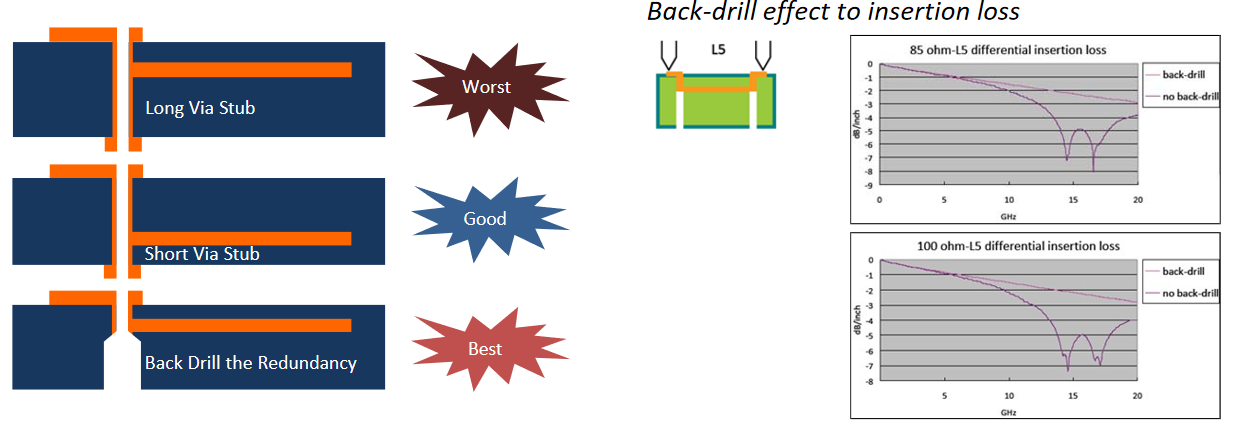

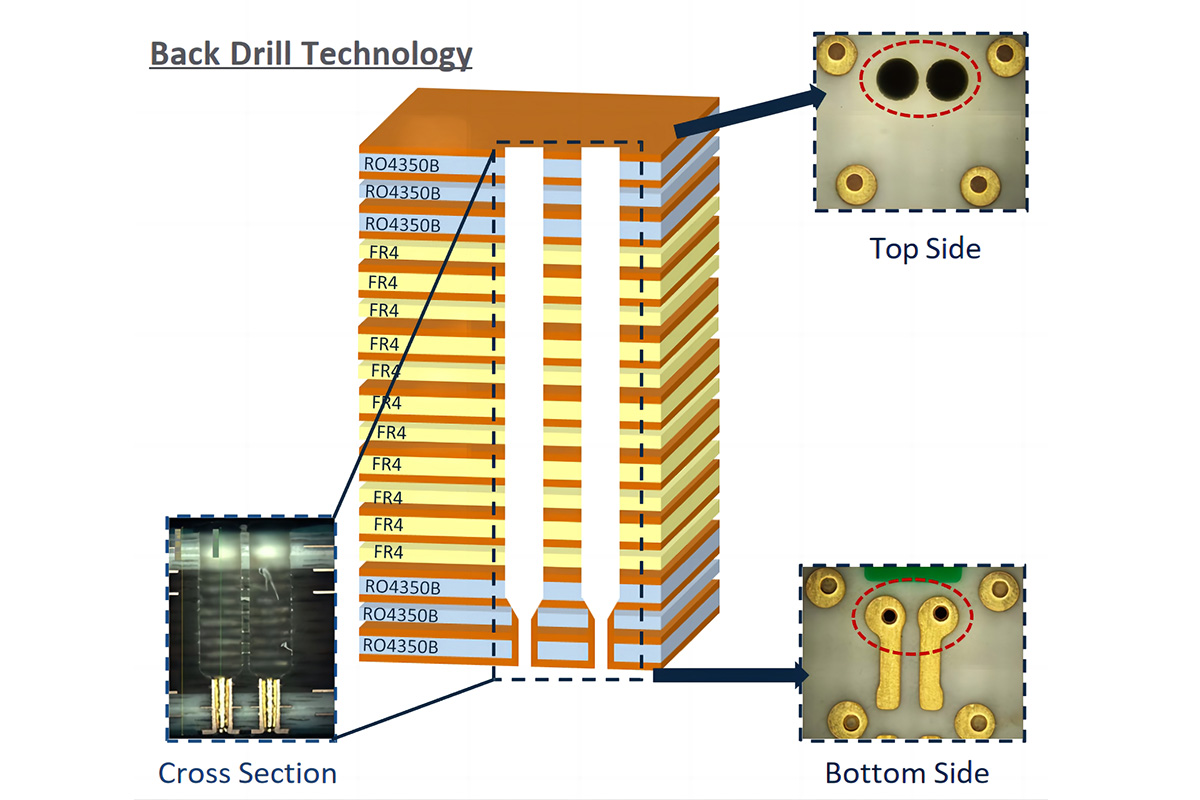

Back Drill Technology

● Microstrip traces should have no vias, they must be probed from the trace side.

● Trace on the secondary side should be probed from the secondary side(The launch side should be on that side).

● The good design is that stripline traces should be probed from whichever side most reduces the via stub.

● The best results for stripline will be obtained by using short vias that are backdrilled.

Product Application: Automotive radar sensor

Product Details:

4 Layer PCB with hybrid material (Hydrocarbon + Standard FR4)

Stack up: 4L HDI / Asymmetric

Challenge:

High frequency material with Standard FR4 Lamination

Controlled depth drill

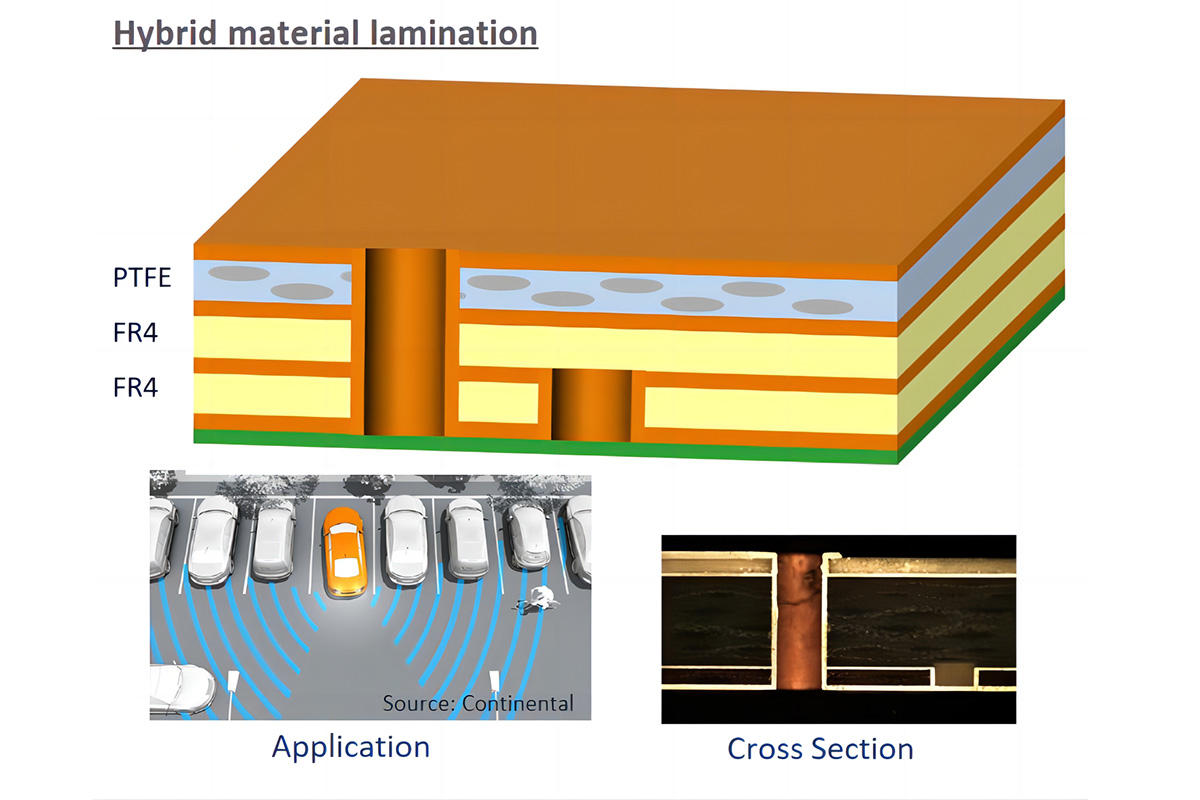

Product Application: Automotive radar sensor

Product Details:

4 Layer PCB with hybrid material (Hydrocarbon + Standard FR4)

Stack up: 4L HDI / Asymmetric

Challenge:

High frequency material with Standard FR4 Lamination

Controlled depth drill

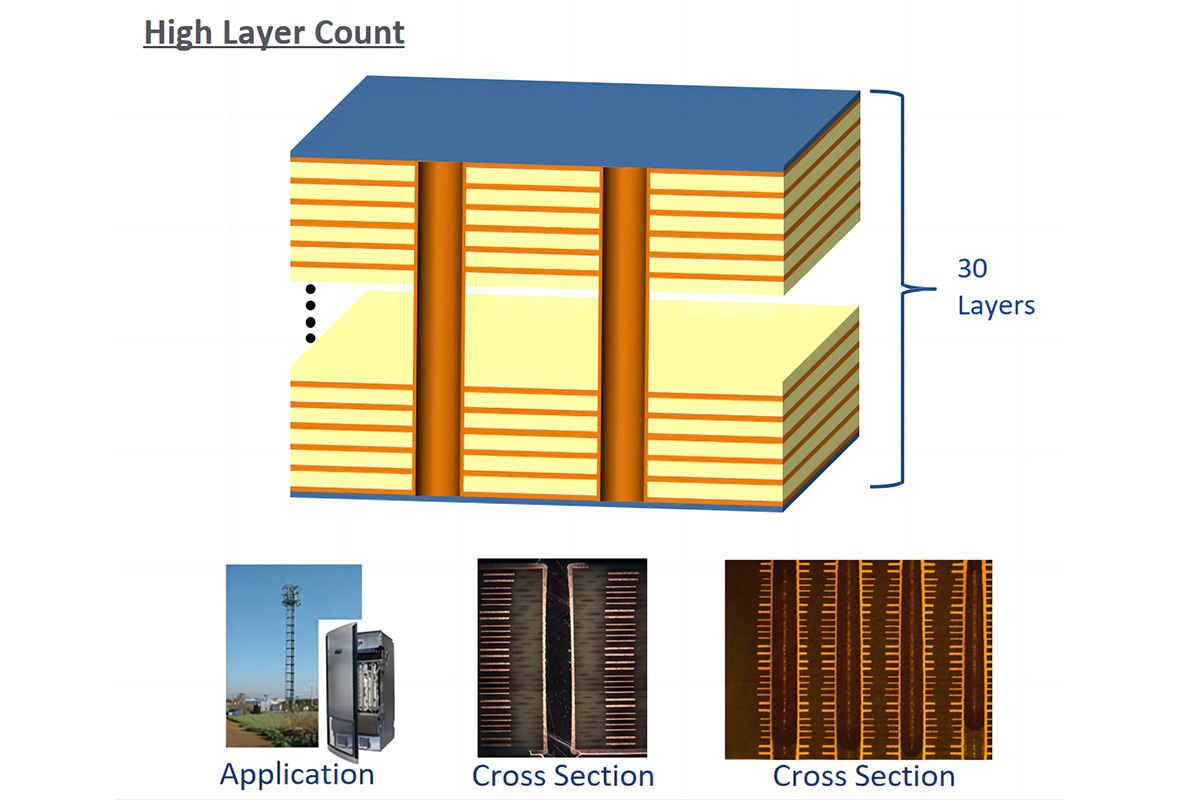

Product Application:

Base station

Product Details:

30 Layers (Homogeneous material)

Stack up: High layer count / Symmetric

Challenge:

Registration for each layers

High aspect ratio of PTH

Critical lamination parameter

Product Application:

Memory

Product Details:

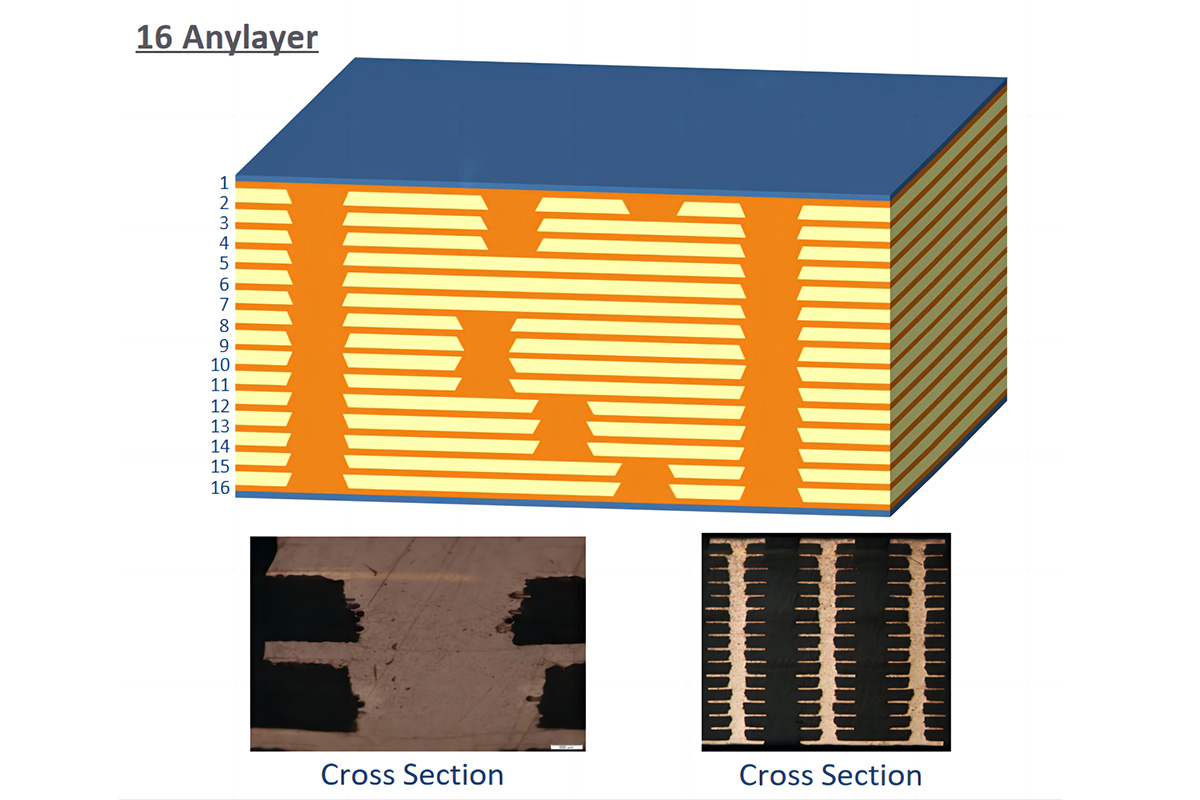

Stack up: 16 Layers Anylayer

IST Test: Condition:25‐190℃ Time:3 min, 190‐25℃ Time:2min, 1500 Cycles. Resistance change rate≤10%, Test method:IPC‐TM650‐2.6.26. Result: Pass.

Challenge:

Laminating more than 6 times

Laser vias accuracy

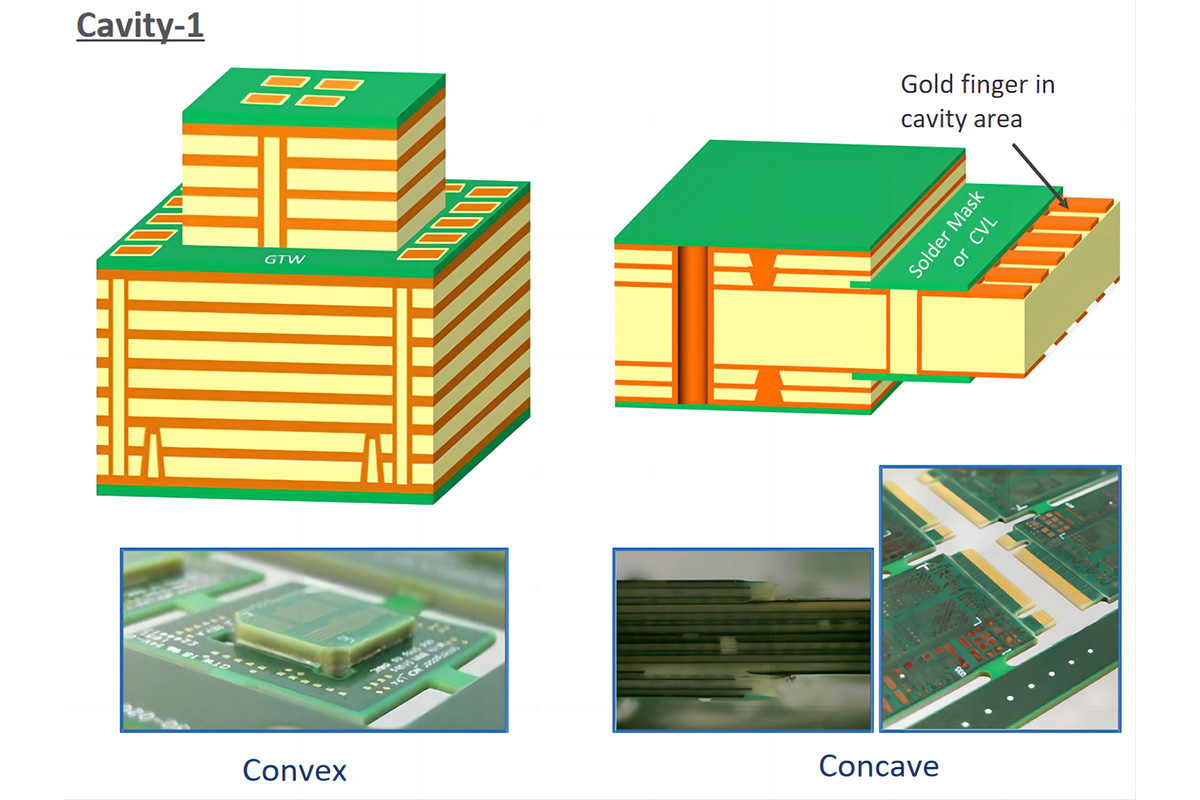

Product Application:

Memory

Product Details:

Stack up: Cavity

Material: Standard FR4

Challenge:

Using De‐cap technology on Rigid PCB

Registration between layers

Less squeeze out at the step area

Critical beveling process for the G/F

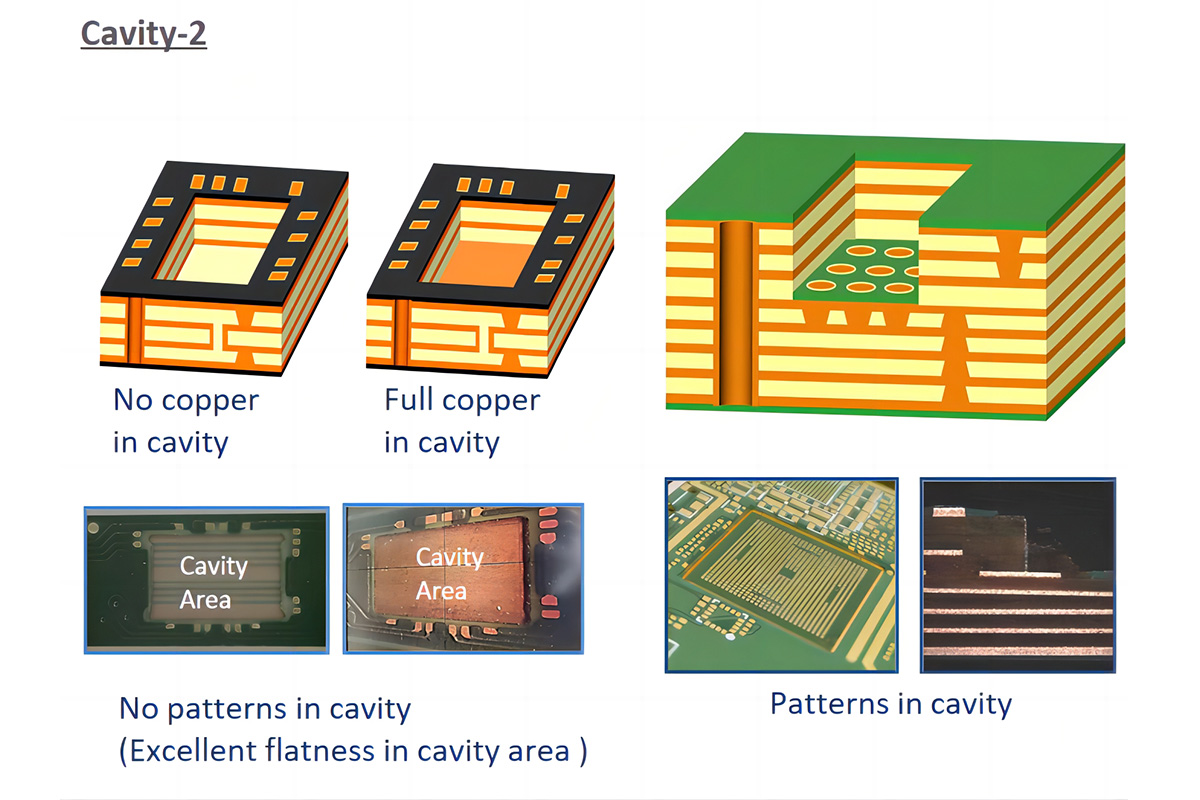

Product Application:

Camera Module / Notebook

Product Details:

Stack up: Cavity

Material: Standard FR4

Challenge:

Using De‐cap technology on Rigid PCB

Critical laser program and parameters in De‐cap process

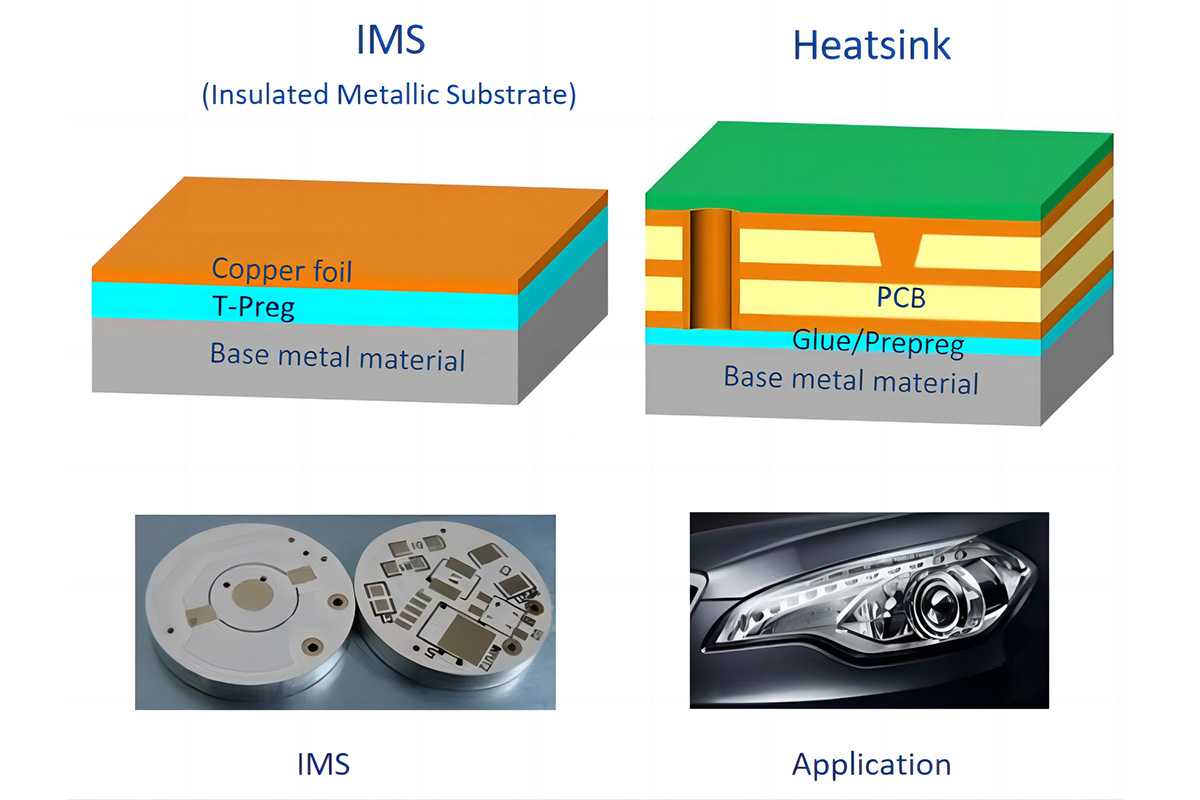

Product Application:

Automotive lamps

Product Details:

Stack up: IMS / Heatsink

Material: Metal + Glue/Prepreg + PCB

Challenge:

Aluminum base and copper base (single layer)

Thermal conductivity

FR4+ Glue/Prepreg + Al lamination

Advantages:

Great Heat Dissipation

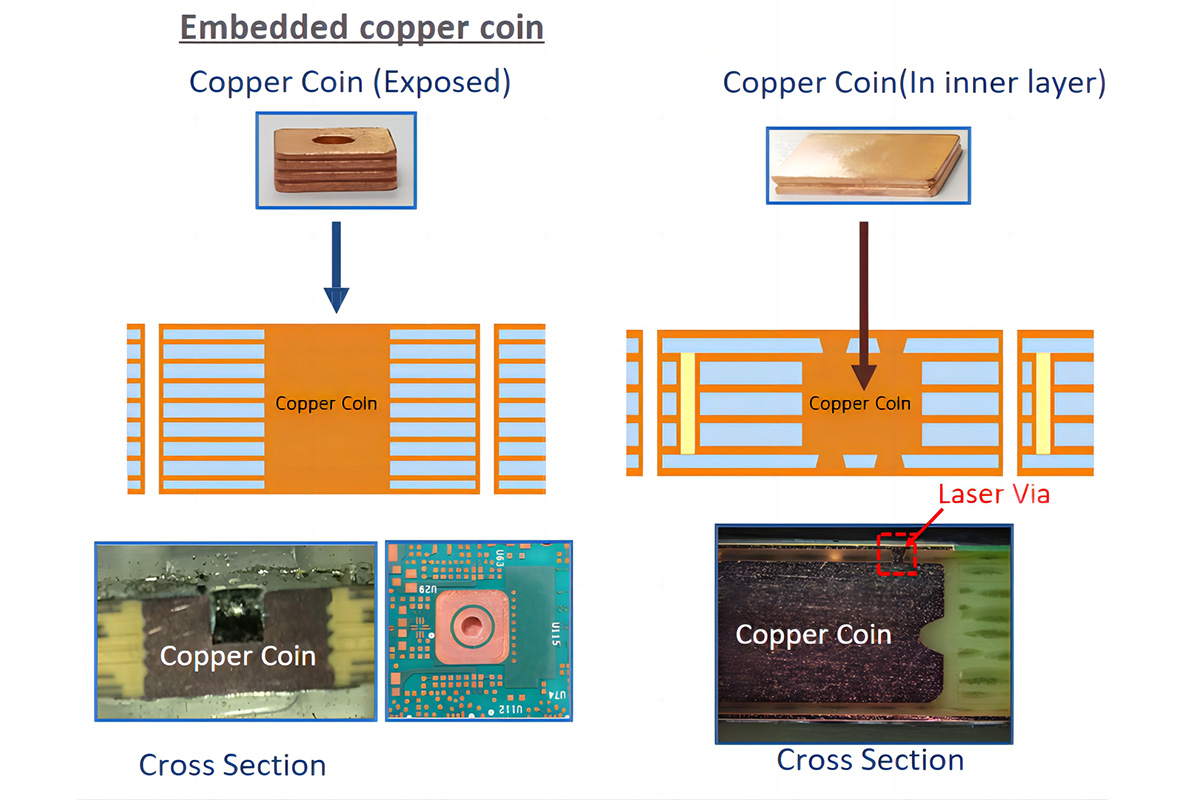

Product Details:

High speed material (Homogeneous)

Stack up: Embedded copper coin / Symmetric

Challenge:

Accuracy of coin dimension

Accuracy of lamination opening

Critical resin flow

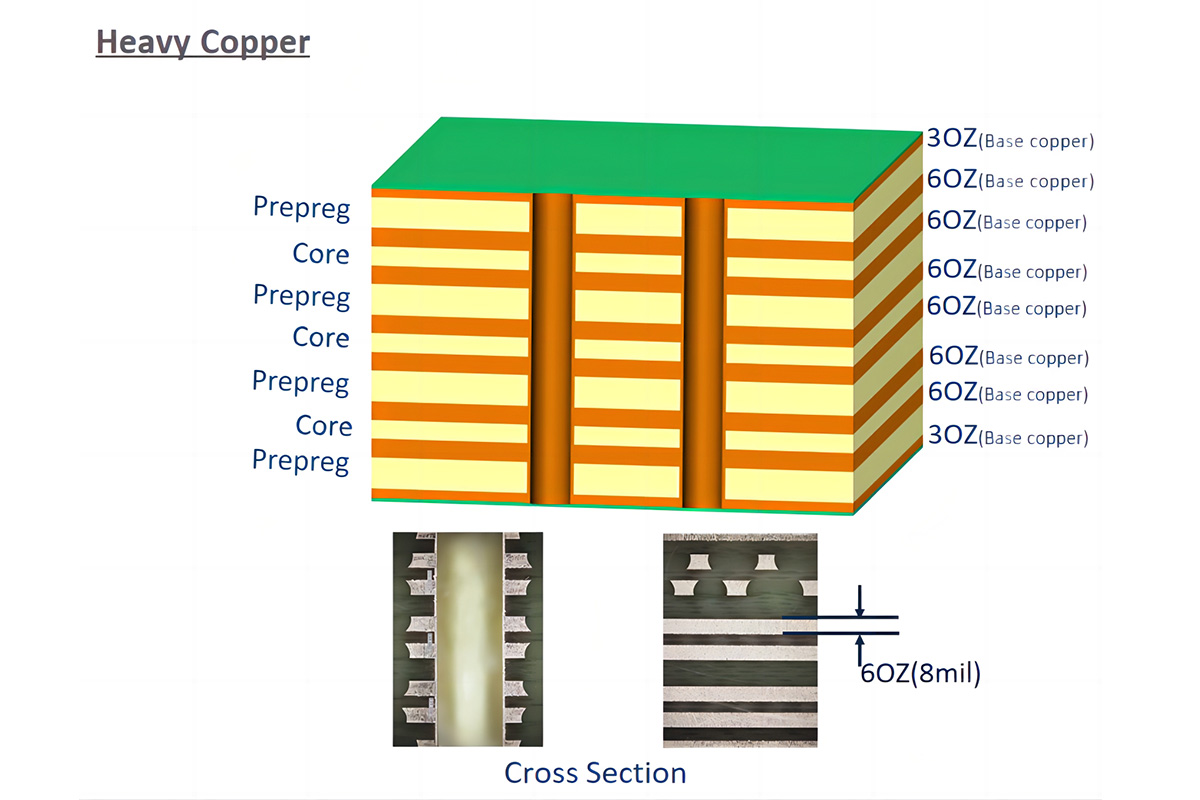

Product Application:

Automotive / Industrial / Base station

Product Details:

Internal layer base copper 6OZ

External layer base copper 3OZ/6OZ Stack up:

6OZ copper weight in internal layer

Challenge:

6OZ copper gap filled fullly with epoxy

No drift in lamination processing

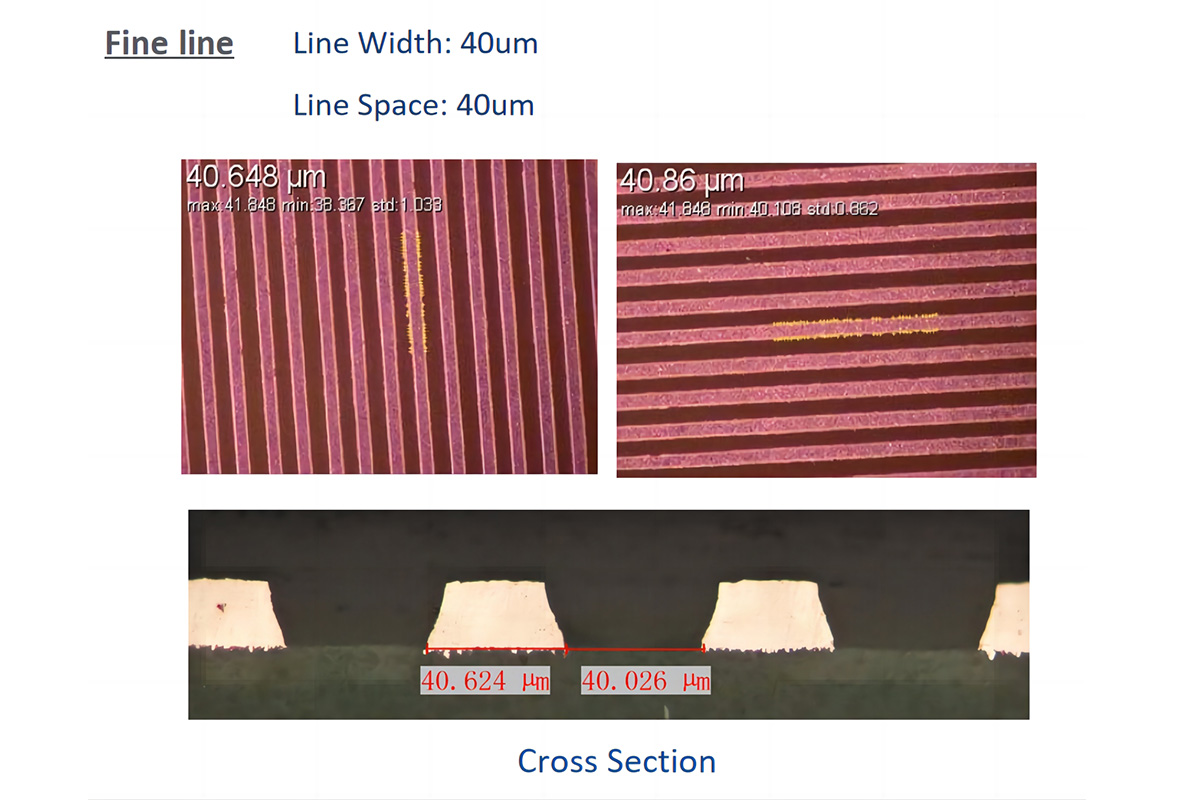

Product Application:

Smart phone / SD Card / SSD

Product Details:

Stack up: HDI / Anylayer

Material: Standard FR4

Challenge:

Very low profile/RTF Cu foil

Plating uniformity

High resolution dry film

LDI Exposure (Laser Direct Image)

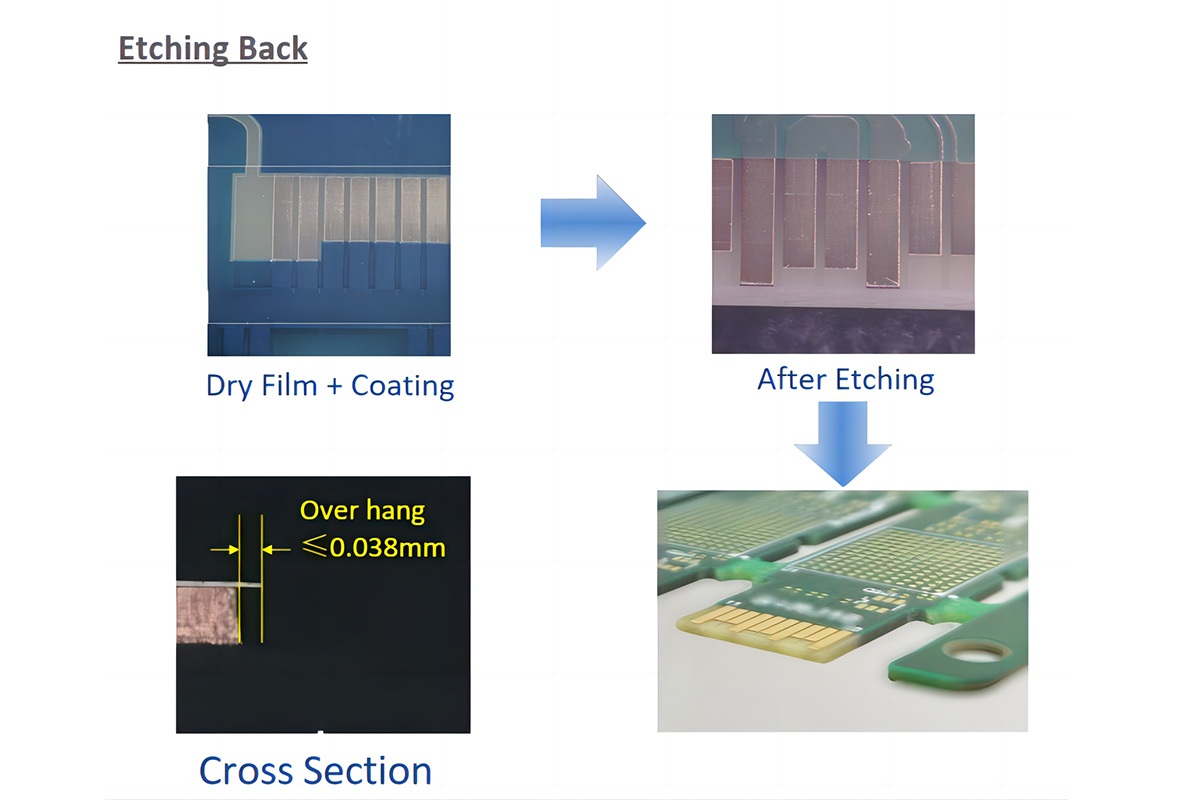

Product Application:

Communication / SD Card / Optical Module

Product Details:

Stack up: HDI / Anylayer

Material: Standard FR4

Challenge:

None gap at the finger edge when PCB in the plating gold processing

Special resistant film

Product Application:

Industrial

Product Details:

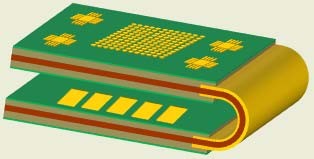

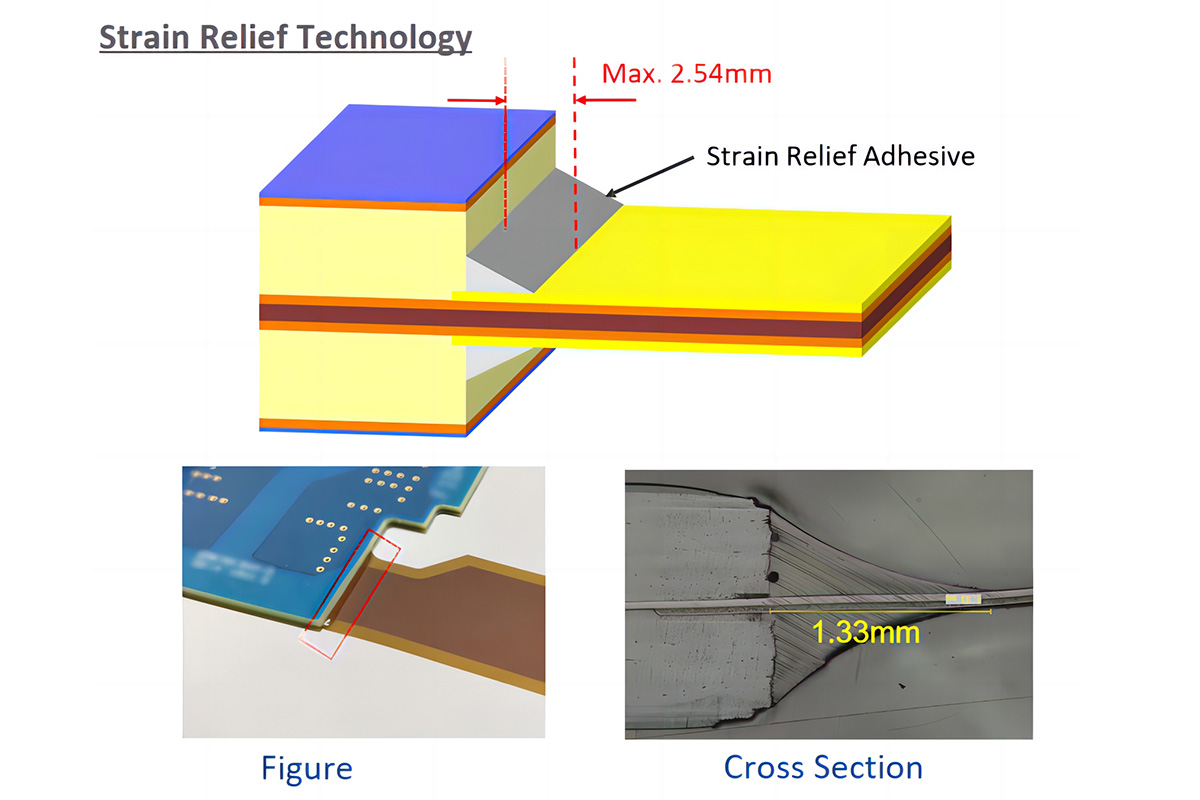

Stack up: Rigid‐Flex

With Eccobond at Rigid‐Flex transformation

Challenge:

Critical moving speed and depth for shaft

Critical air pressure parameter