Multilayer PCB, nawuphi na umaleko HDI PCB

Umaleko ophezulu / nawuphi na umenzi we-HDI

Inkcazo ye-HDI (i-High Density lnterconnection) ibhodi yesekethe ibhekisa kwi-Microvia PCB ene-aperture engaphantsi kwe-6mm, i-Hole Pad engaphantsi kwe-0.25mm, ukuxinana koqhagamshelwano olungaphezulu kwamanqaku angama-130 / iyure yesikwere, ukuxinana kweengcingo ezingaphezulu. ngaphezu kwe-117 amanqaku / isikwere seyure, kunye nobubanzi bomgca / isithuba esingaphantsi kwe-3mi/3mi.

Ukuhlelwa kwe-HDI PCB : I-1 layer, i-2 layer, i-3 layer kunye nayiphi na i-HDI

Isakhiwo se-HDI se-1: 1 + N + 1 (cinezela kabini, i-laser kanye).

Isakhiwo se-2 layer HDI : 2 + N + 2 (cinezela amaxesha ama-3, i-laser kabini).

Isakhiwo se-3 se-HDI: 3 + N + 3 (cinezela amaxesha ama-4, i-laser 3 amaxesha).

Nawuphi na umaleko we-HDI ubhekisa kwi-HDI enokuthi iqhube i-laser drilling ukusuka kwi-PCB engundoqo, kwelinye igama, ithetha ukuba i-laser drilling iyadingeka ngaphambi kokucinezela.

Izinto eziluncedo ze-HDI PCB

1. Inokunciphisa iindleko zePCB. Xa uxinaniso lwe-PCB lunyuka lube ngaphezu kwe-8 umaleko, luveliswa ngendlela ye-HDI kwaye iindleko zalo ziya kuba ngaphantsi kweenkqubo zokucinezela eziyinkimbinkimbi zendabuko.

2. Ukwandisa ubuninzi beesekethe ngokudibanisa iibhodi zeesekethe eziqhelekileyo kunye namacandelo

3. Inzuzo ekusebenziseni iteknoloji yokupakisha ephezulu

4. Ukufumana ukusebenza kombane okungcono kunye nokuchaneka komqondiso

5. Ukuthembeka okungcono

6. Inokuphucula ukusebenza kwe-thermal

7. Inokunciphisa ukuphazamiseka kwamaza erediyo, ukuphazamiseka kwamaza e-electromagnetic, kunye nokukhutshwa kwe-electrostatic (RFI/EMI/ESD)

8. Ukwandisa ukusebenza kakuhle koyilo

Umahluko ophambili phakathi kwe-HDI kunye ne-PCB eqhelekileyo

1. I-HDI inomthamo omncinci kunye nobunzima obulula

I-HDI PCB yenziwe nge-PCB enamacala amabini emveli njengondoqo, ngokuqhubeka nokwakhiwa kunye nokulanyiswa. Olu hlobo lwebhodi yesekethe eyenziwe ngokuqhubeka kokubeka ukwaleka ikwabizwa ngokuba yi-Build-up Multilayer (BUM). Xa kuthelekiswa neebhodi zeesekethe zemveli, iibhodi zeesekethe ze-HDI zineenzuzo ezifana nokukhanya, ukuncipha, ukufutshane kunye nokuncinci.

Uqhagamshelo lombane phakathi kweebhodi zesekethe ze-HDI luphunyezwa nge-conductive ngokusebenzisa umngxuma, ukungcwatywa/ukumfamekisa ngoqhagamshelo, olwahlukileyo ngokwesakhiwo kwiibhodi zesekethe ze-multi-layer. Micro wangcwatywa / iimfama nge isetyenziswa ngokubanzi HDI PCBs. I-HDI isebenzisa ngokuthe ngqo i-laser drilling, ngelixa i-PCBs eqhelekileyo idla ngokusebenza ngomatshini, ngoko ke inani leeleya kunye ne-aspect ratio ihlala ihla.

2. Inkqubo yokuVeliswa kwebhodi ephambili ye-HDI

Uphuhliso olunoxinaniso oluphezulu lwe-HDI PCB lubonakaliswa ikakhulu kuxinaniso lwemingxuma, iisekethe, iipadi ze-solder kunye nobukhulu be-interlayer.

● Imingxunya emincinci: IiPCB zeHDI zinemingxuma eyimfama kunye nolunye uyilo oluncinci lokutyhubela umngxuma, olubonakaliswa ikakhulu kwiimfuno eziphezulu zetekhnoloji yokwenza umngxuma omncinci kunye nobungakanani bepore obungaphantsi kwe-150um, kunye neendleko, ukusebenza kakuhle kwemveliso kunye nesikhundla somngxuma. ulawulo oluchanekileyo. Kwiibhodi zesekethe zomaleko amaninzi, kukho imingxunya kuphela kwaye akukho mingxunya mincinci ingcwatyiweyo/emfamekileyo

● Ukucokiswa kobubanzi bomgca/isithuba: kubonakaliswa ikakhulu kwiimfuno ezingqongqo eziya zisiba ngqongqo kwiziphene zocingo kunye noburhabaxa bomphezulu wocingo. Ububanzi bomgca ngokubanzi/isithuba abugqithi kuma-76.2um

● Ubuninzi beepadi eziphezulu: Ubuninzi bee-solder joints bukhulu kune-50 / cm2

● Ukucuthwa kobungqingqwa be-dielectric: Oku kubonakaliswa ikakhulu kwindlela yokuqina kwe-dielectric ye-interlayer ephuhlayo ukuya kwi-80um nangaphantsi, kwaye imfuno yobukhulu obufanayo iya iba ngqongqo ngakumbi, ngakumbi kwii-PCB ezinoxinaniso oluphezulu kunye nokupakishwa kwesubstrates ezinophawu lolawulo lwe-impedance.

3. I-HDI PCB inomsebenzi ongcono wombane

I-HDI ayinakukwenza kuphela ukuyilwa kwemveliso yokuphela, kodwa ikwanemigangatho ephezulu yokusebenza kwe-elektroniki kunye nokusebenza kakuhle ngaxeshanye.

Ukuxinana koqhagamshelwano olwandisiweyo lwe-HDI luvumela ukomeleza amandla omqondiso kunye nokuthembeka okuphuculweyo. Ukongeza, ii-PCB ze-HDI ziphuculwe ngcono ekunciphiseni ukuphazamiseka kwamaza kanomathotholo, ukuphazamiseka kwamaza ombane, ukukhutshwa kwe-electrostatic kunye nokuhanjiswa kobushushu, njl.njl. I-HDI ikwamkele itekhnoloji yolawulo lwenkqubo yedijithali ngokupheleleyo (DSP) kunye nobuchwepheshe obunamalungelo awodwa omenzi wechiza. ukulayisha kuluhlu olupheleleyo kunye nomthamo owomeleleyo wexeshana elifutshane.

4. Ii-PCB ze-HDI zineemfuno eziphezulu kakhulu zokungcwatywa nge/umngxuma weplagi

Njengoko kunokubonwa apha ngasentla, zombini ngokobukhulu bebhodi kunye nokusebenza kombane, i-HDI iphezulu kune-PCB eziqhelekileyo. Yonke ingqekembe inamacala amabini, kwaye elinye icala le-HDI, njenge-PCB ephezulu, umda wayo wokuvelisa kunye nobunzima benkqubo buphezulu kakhulu kuneePCB eziqhelekileyo, kwaye kukho imiba emininzi ekufuneka iqwalaselwe ngexesha lemveliso, ngakumbi ukungcwatywa nge-PCB. kunye nomngxuma weplagi.

Okwangoku, eyona ndawo iphambili yentlungu kunye nobunzima kwimveliso ye-HDI kunye nokuveliswa kukungcwatywa kunye nomngxuma weplagi. Ukuba i-HDI engcwatywe ngomngxuma weplagi akwenziwanga kakuhle, iingxaki ezibalulekileyo zomgangatho ziyakwenzeka, kubandakanywa imiphetho engalinganiyo, ubukhulu obuphakathi obungalinganiyo kunye nemingxuma kwi-solder pad.

● Umphezulu webhodi ongalinganiyo kunye nemigca engalinganiyo inokubangela ukuba izinto ezenzeka elunxwemeni kwindawo ezitshoneyo, nto leyo ekhokelela kwiziphene ezifana nezikhewu zemigca kunye nokuqhawuka.

● I-impedance yeempawu zinokuguquguquka ngenxa yobunzima be-dielectric engalinganiyo, okubangela ukungazinzi komqondiso

● Iiphedi ze-solder ezingalinganiyo zikhokelela kumgangatho ophantsi wokupakisha olandelayo, okukhokelela kwilahleko edibeneyo kunye neqela leenxalenye.

Ke ngoko, ayizizo zonke iifektri ze-PCB ezinamandla kunye namandla okwenza i-HDI kakuhle, kwaye i-RICH PCBA ibisebenza nzima kule minyaka ingaphaya kwama-20.

Sifumene iziphumo ezilungileyo kuyilo olukhethekileyo olunjengokuchaneka okuphezulu, ukuxinana okuphezulu, i-high-frequency, i-high-speed, i-TG ephezulu, iipleyiti ze-carrier kunye ne-RF PCB. Sikwanawo amava okuvelisa atyebileyo kwiinkqubo ezikhethekileyo ezinje nge-ultra-thick, oversized, copper engqingqwa, ihigh-frequency hybrid pressure, iibhloko ezifakwe ubhedu, imingxunya enesiqingatha, uqheliso lwangasemva, izixhobo zokulawula ubunzulu, iminwe yegolide, iibhodi zokulawula ezichanekileyo. , njl.

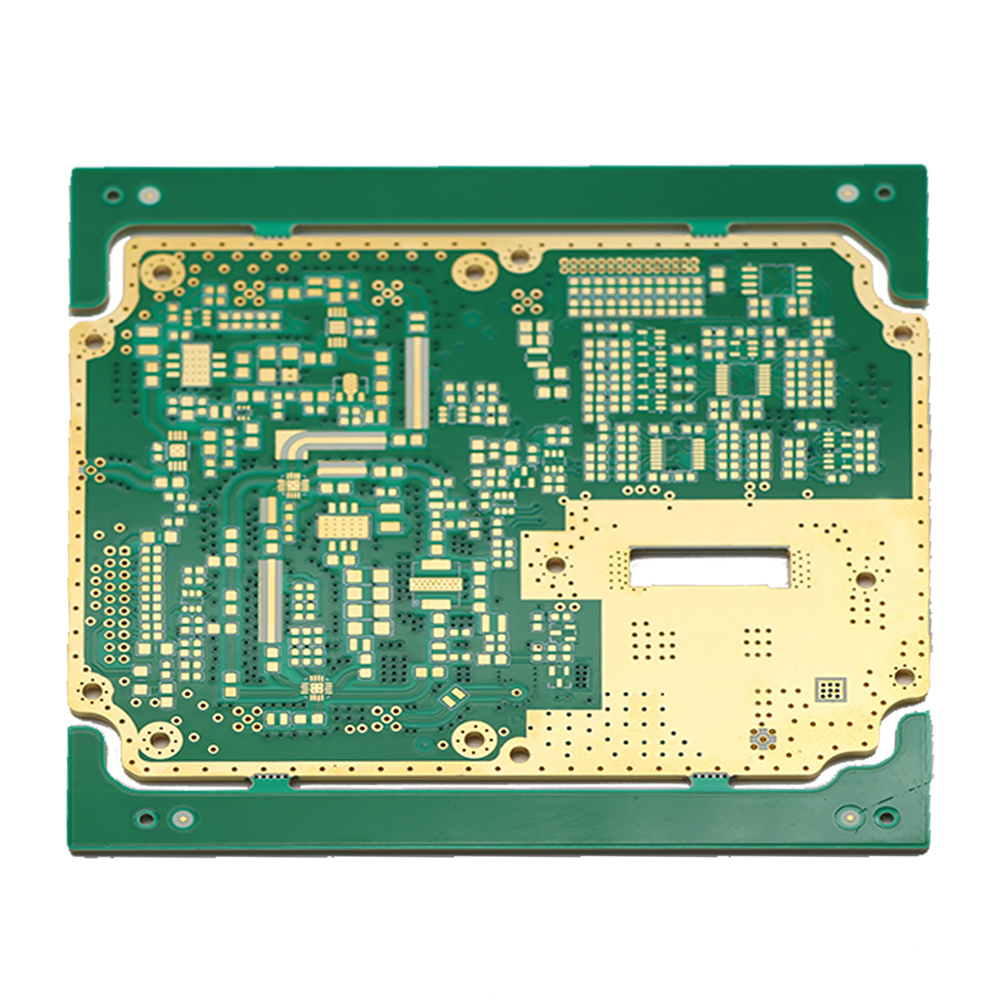

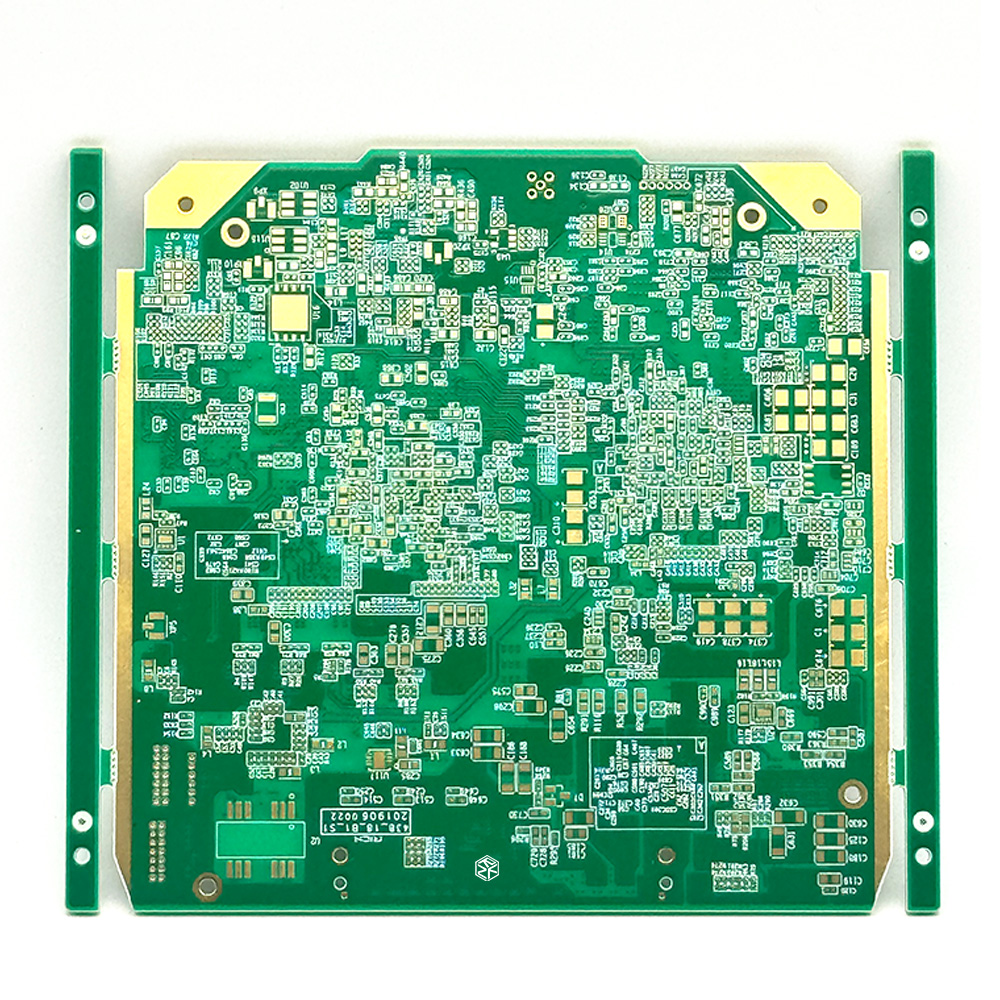

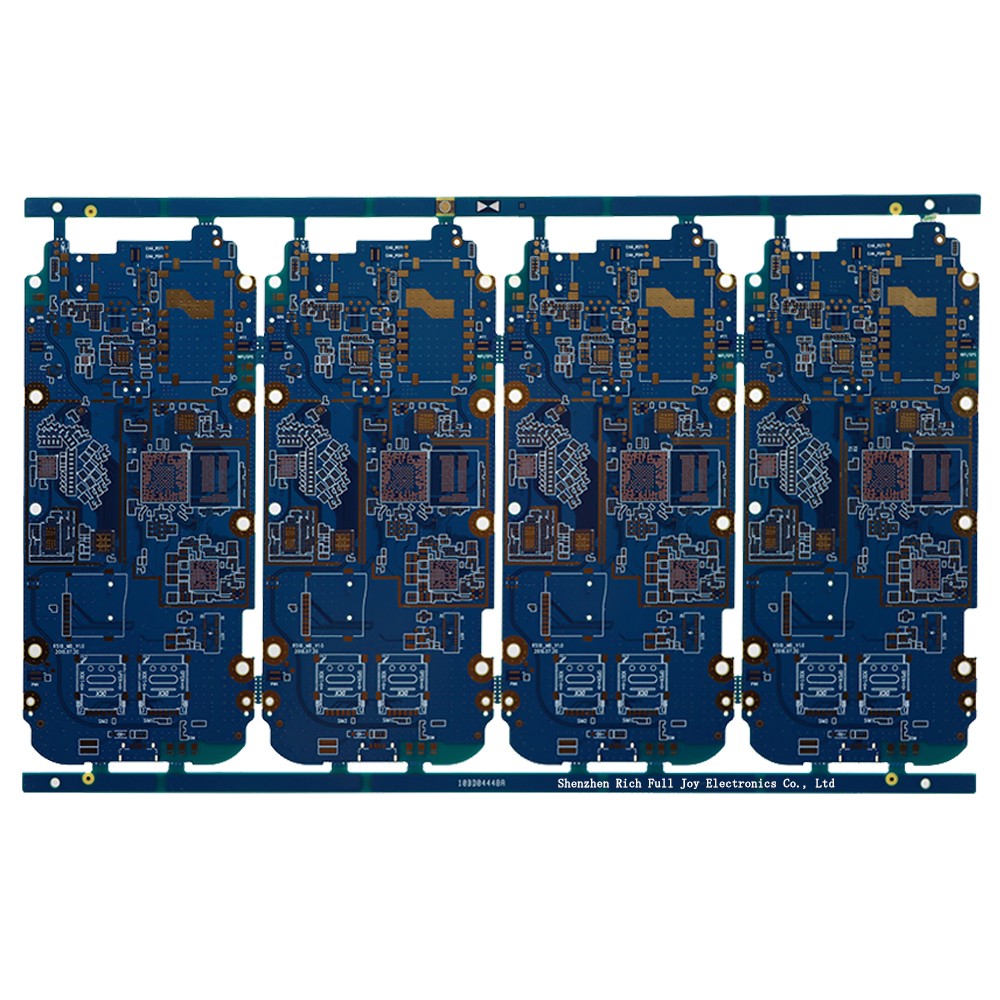

Isicelo (jonga umfanekiso oqhotyoshelweyo ngeenkcukacha)

Ii-PCB ze-HDI zisetyenziselwa kwiinkalo ezininzi ezifana neefowuni eziphathwayo, iikhamera zedijithali, i-AI, abathwali be-IC, izixhobo zonyango, ulawulo lwamashishini, ii-laptops, i-automotive electronics, iirobhothi, i-drones, njl.

Isicelo

Ii-PCB ze-HDI zisetyenziselwa kwiinkalo ezininzi ezifana neefowuni eziphathwayo, iikhamera zedijithali, i-AI, abathwali be-IC, izixhobo zonyango, ulawulo lwamashishini, ii-laptops, i-automotive electronics, iirobhothi, i-drones, njl.